Panametrics’ flowmeter technology supports steel mill with very low-pressure flue gas measurement

Panametrics’ flowmeter technology supports steel mill with very low-pressure flue gas measurement

Summary

Summary A major steel mill in China, with a production capacity of dozens of millions tons per annum, has a long and successful track record of using ultrasonic flowmeters. Very familiar with Panametrics products, the customer has used many Panametrics liquid, gas and flare flowmeters with great success.

However, it also used a competing ultrasonic flowmeter product for flue gas measurement. The customer found it to be unreliable, and wanted to replace it.

Challenge

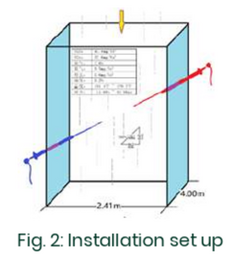

The instrument had to be installed on a 2.4m x 4m large rectangular pipe. The installation had only 1.5 nominal diameter of upstream straigth runs, leading to a non-fully-developed flow profile.

With the two nozzles being far apart, it was challenging to ensure correct alignment leading to potential large offsets and an inability to capture the signal and therefore provide inaccurate and unreliable measurements.

However, on this particular allpication there was no room for measurement errors – the data had to be precise given it fed into the continuous emission monitoring system (CEMS).

Solution

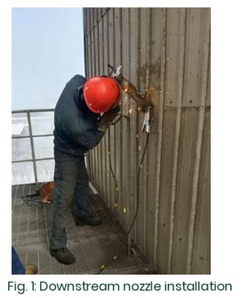

Given the very long path length, the Panametrics Team recommend its DigitalFlow XGM868i gas ultrasonic flow transmitter with T5 transducers at 50 kHz frenquency. This measured the long path with a wide beam angle to ensure an accurate measurement. In parallel, the Panametrics Services Team used a laser alignment tool to obtain an accurate nozzle alignment.

After successful installation and commissioning, the flowmeter solution provided accurate and reliable data. The customer was very satisfied – it could now properly feed its CEMS with the flow measurement data.

As a result of this success, the Panametrics Team are already discussing similar applications across other steel making facilities globally.

Specifications (OPT)

- Fluid: Flue gas

- Pipe size : 2410mm x 4000mm (7.9 ft X 13.1 ft)

- Pipe material: Carbon steel

- Process Temperature: 101 to 129 °C (214 to 264 °F)

- Process pressure: -11 Pa to93 kpa (-0.0016 to 13.5 psig)

- Fluid sound speed : ~390m/s (~1280 ft/s)

Benefits

- Low pressure measurement down to very slight vacuum capability

- No Pressure drop

- Low maintenance

- Long term stability

- Ability to measure in rectangular pipes

- Wide measuring range

Technology used:

Find out more about Panametrics solutions

📍 DigitalFlow XGM868i | Datasheet

💻 Panametrics Flow Meter Solutions