Rasmus Wood Fired Plant - Scrubber application

This customer supplies district heating and electricity for the region of Sønderborg. The plant processes about 70.000 tons of waste a year. For one of their waste applications a MAG meter failed within 6 months, and was successfully replaced with a Panametrics Aquatrans AT600.

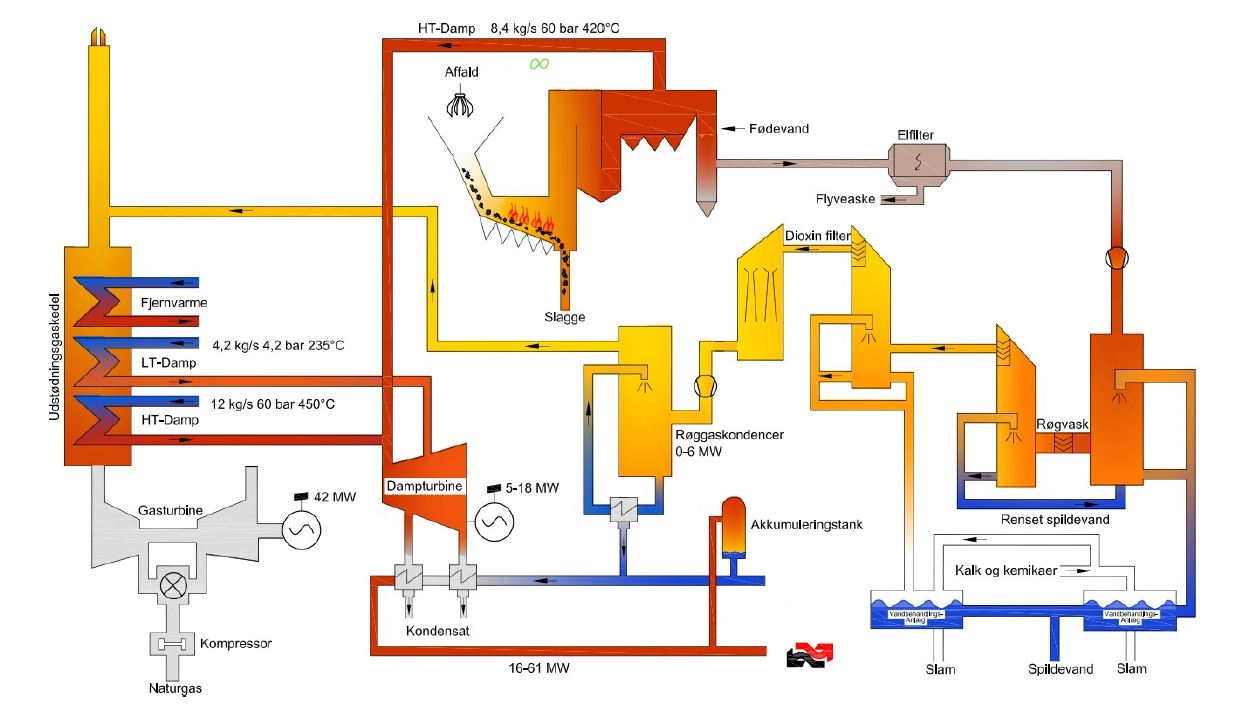

This is a “cogeneration” plant that runs both on waste and natural gas. Cogeneration basically consists of two units; a waste incineration plant where the energy from the waste is converted into electricity and district heating, and a gas turbine generator plant that produces electricity and district heating based on natural gas from the gas extraction areas in the North Sea.

Historically, incineration of waste has been developed as a method of reducing the amount of waste that is or should be landfilled. After the incineration process, the weight of the waste is reduced to approximately 21% and its volume is only about 6% of the original.

The cogeneration plant has recently been extended with a Geothermal plant and a Gasification furnace. The picture to the right shows the pipeline from the Geothermal plant to the existing cogeneration plant. The Geothermal plant sources water with a temperature of 48°C from a depth of 1200m. Heat pumps are used to extract energy from this water for district heating. The geothermal plant in combined with the heat pumps, and produce heated water for the district heating grid. The gasification plant burns the gassified wood pellets, and then heats district water as well. Meaning, the 2 plants are only connected via the district heating grid. A Panametrics AquaTrans AT600 was supplied to control the heat pumps.

The Gasification furnace runs on biomass. Wood pellets are heated to a temperature where they release their gas. As mentioned above, all energy used for heating of district heat water. The flue gases from the combustion of waste are purified by a scrubber that "scents" the smoke for acidic components and heavy metals as well as SO2 and Dioxin. The wash water from this scrubber is purified in the plant's own wastewater treatment plant.

Benefits: • Easy to install • Not affected by contaminates • 4-20mA output

Initially a MAG meter was installed on the water from the scrubber. After half a year it stopped working. The installation was done with a remote electronic on the wall, and when the electrician performed an on-site check nothing showed on the display. Upon opening the display, water came out of the electronics. They found, that the glands around the electrodes in the MAG meters were etched and water had entered into the surrounding housing of the MAG meter, traveled inside the cable going from the MAG meter to the remote display, and finally destroyed both the MAG meter and the electronic unit on the wall. The water from the scrubber is acid and contaminated with particles from the flue gas.

For the heat pumps water flow at high temperature (>140°C), the customer requested to perform the measurement without any process shutdown. Plastic pipes were installed in the previous MAG meter positions, a Panametrics AquaTrans AT600 meter replaced the MAG meter and has not had any issues since.

• Aquatrans AT600 with high temperature transducers were successfully used for the heat pumps water lines • Heat pumps: from 100°C to 150°C (212°F to 302°F) Water from scrubber: 30°C (86°F) • Heat pumps: DN400 (16") Water from scrubber: DN50 (2")