Ultrasonic Measuring Techniques

The main purpose of the ultrasonic testing of materials is looking for and evaluating locations in materials which contain discontinuities and whereby advantage is taken of the interference to the wave propagation by such locations. At the same time a large number of measuring methods develop which take advantage of the numerous relationships in the interaction effects between sound waves and the material for a more accurate determination of the properties of material, from the physics of solids up to the production control (see chapter 2). From this range outside the flaw locating, and which is somehow unjustly called "ultrasonic measuring techniques" various methods have gained practical significance. The basics for all methods is either the influencing of the sound velocity (sound transit time) or the sound attenuation through the material in which the sound wave travels (see chapter 2).

The well thickness measurement uses the known sound velocity to determine the wall thickness. For this there are pulse transit time instruments with either analog or digital displays e. g. Corrometer, Caliper or D-Meter. A resonance method can also be used as, for example with the "Predef-method" (pulse resonance method with delayed feed back). The development of the electronic components for directly counting out the transit time is at present in such an advanced stage that, by using them, the same accuracy can be reached as was obtained previously using an Interferometer or a corresponding method of phase superimposition.

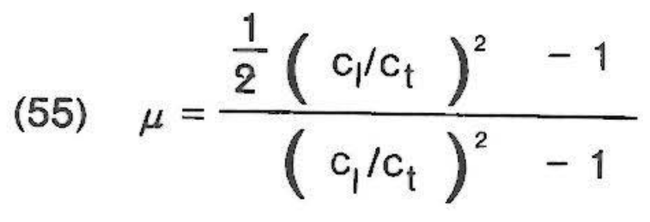

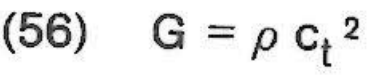

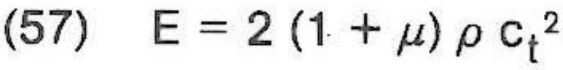

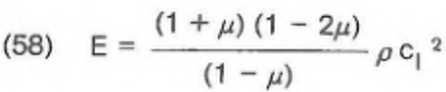

Elastic constants of materials are very closely related to the sound velocities of longitudinal and transverse waves. By transposing in equations (3) and (4) in chapter 5 one obtains the following relationships for the modulus of elasticity E, the shear modulus G as well as the Poisson ratio y. In addition to the sound velocities ctrans and ciong (m/s) all that is needed is the density p of the material (in kg/m'):

The dimension for G and E is kg/ms 2 (= Pascal) The table 1 is a survey of the acoustical data of usual materials. A special method for determining the sound velocity is the goniometer method which takes advantage of the reflection and refraction at Interfaces (see chapter 10).

Stress measurements during elastic deformation can be similarly taken by measuring the sound velocity of the transverse or surface waves.

Structure examination is an important application of ultrasonic measuring techniques — especially with castings, concrete or ceramics and where sound velocity and sound attenuation are measured. (A survey of the sound velocity of materials is given in table 7). The sound velocity is influcenced by the graphite content and formation. Similarly, with castings, ductility and hardness are related to the sound velocity. For determining the mechanical characteristics however the sound attenuation is often of greater advantage than the sound velocity because it reacts with far more sensitivity to the changes in the structure. In metallurgy and solid state physics one can confirm deformation in the plastic and elastic ranges by changes in the sound attenuation.

Measuring hardness ultrasonically is based on the different damping of the oscillations of a metal rod in an UCI hardness meter, if the Vickers indenter on top of the rod is pressed to the surface of the test specimen. (Ultrasonic contact impedance) (fig. 51). The viscosity of fluids can be determined in a similar manner.