"Space exploration streamlined"

How spacecraft manufacturers can transform their operations and optimize data management on a global scale

In 2022 alone, the global aerospace industry generated a turnover of 546 billion euros – and the trend is rising. The industry is booming, but production processes are complicated and involve long lead times. This is where non-destructive testing and digital solutions come into play. By integrating the Krautkrämer USM 100, Waygate Technologies helped a spacecraft manufacturer achieve significant efficiency improvements. These resulted in reduced inspection time, lower cost per inspection and improved quality standards across all production facilities, contributing to further success in the industry.

Benefits

• Decreased inspection durations, resulting in substantial time and cost reductions.

• Streamlined data organization, accessibility and sharing between sites.

• Increased operational efficiency, freeing up inspectors for other tasks and ensuring consistent quality across all sites.

Challenge

Like many others in the industry, the spacecraft manufacturer faced a number of challenges in its testing procedures:

• Manual data transfer process was time-consuming

• No centralized data repository

• Data managed independently at each site

• Retrieving and analyzing data across sites was cumbersome

• Slow manual data capture process caused bottlenecks

• Lack of visibility and coordination across sites

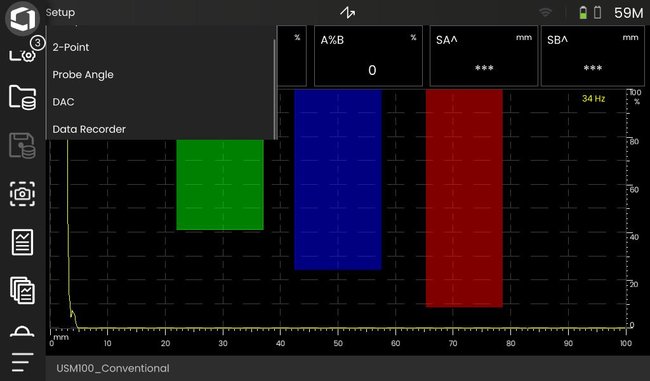

Additionally, the company was using multiple UT devices for thickness and defect detection, resulting in complex and inefficient inspection procedures. To simplify workflows and streamline testing, the company needed a single instrument that could cater to these needs and effectively perform both thickness and defect testing. The solution came in the form of the Krautkrämer USM 100, a portable, highly versatile flaw detector with smartphone-like features. The instrument is ergonomically designed with a large touch screen and buttons that allow seamless ambidextrous operation for unmatched ease of use. Digital features include a world-class user interface that simplifies set-up, training time and updates. In addition to flaw and sub-surface crack detection, the unit also offered thickness measurement capabilities, meeting the need for versatility in inspection tools. The spacecraft manufacturer was able to increase efficiency by reducing inspection time, capturing more accurate data for a given inspection.

Solution

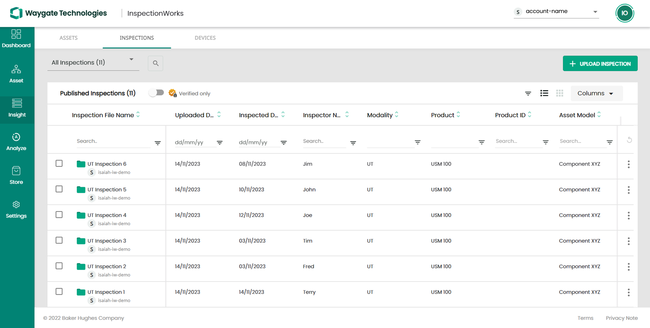

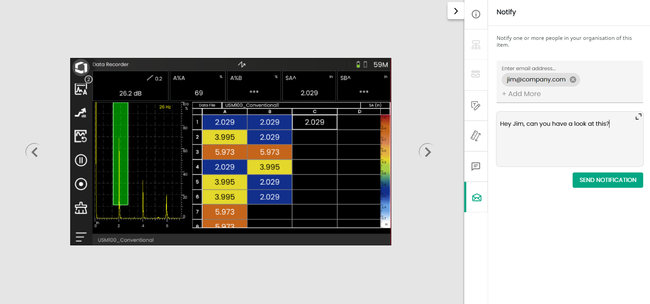

Designed for an interconnected world, USM 100 boasts a range of connectivity features, including apps to customize workflows and a best-in-class user interface. The deployment of the device resulted in significant time savings for the spacecraft manufacturer. To ensure consistency and efficiency across all their facilities, the solution was standardized successfully. Future plans include the integration of InspectionWorks (IW) Insight – a secured, agnostic cloud inspection data management environment that can ingest data via PC upload. This data transfer is made seamless with InspectionWorks-enabled devices such as the USM 100.

• Engineers and inspectors can easily view and analyze stored data.

• Streamlined data collection and transfer processes result in significant time savings.

• Inspection data can be easily shared with other personnel for collaborative review and analysis.

This combination allows engineers and inspectors to easily view and analyze stored data. It also overcomes the challenge of inspectors and engineers needing access to all captured data at different locations.

“At Waygate Technologies, we are proud to be at the forefront of advancing space exploration through innovative solutions. Our collaboration with spacecraft manufacturers has not only streamlined their operations but has also contributed to the success of their space exploration endeavors. We remain committed to providing cutting-edge technology and expertise to empower our partners in reaching for the stars.“

Alexis Herve

Director Global Operations - InspectionWorks

Waygate Technologies

A particularly favored feature among the team was the touchscreen’s capability to move and size gates, greatly optimizing gate programming and further reducing setup time.

Digital features of the USM 100 include a user interface that simplifies the setup process, reduces training time and efficiently handles updates.

Through InspectionWorks Insight, data can be stored centrally, and inspections can be conveniently viewed by different inspectors.

Results

These benefits provide the customer with key elements of success, including freeing up inspectors’ time to focus on critical activities and consistent quality standards across all manufacturing facilities, which strengthen the spacecraft manufacturer’s reputation and reliability. The implementation of the USM 100 not only optimized inspection processes but also had a broader positive impact on operational efficiency and cost-effectiveness, contributing to the client’s further success in the industry.

“By partnering with with Waygate Technologies, we’ve

methodically streamlined our inspection processes,

resulting in significant time and cost savings. This

heightened operational efficiency has allowed our

inspectors to redirect their efforts while maintaining

consistent quality standards across all our sites. This

partnership has undoubtedly propelled us forward in

our quest for cosmic exploration.”

Customer Voice