The Beginning of Bently Nevada's Reciprocating Compressor Monitoring Platform

In the mid 1970's, a Bently Nevada customer in the Netherlands had a question for our engineering team: "Could a Bently proximity probe be used to observe a piston rod as it dropped due to rider band wear?" The answer..."Well, yes it could."

That seemingly small special request marked the beginning of Bently Nevada's first monitor designed specifically for reciprocating compressors when a modified thrust position monitor became the first rod drop monitor. It also marked the start of Bently Nevada's now lengthy association with condition monitoring solutions for reciprocating compressors.

From those humble beginnings nearly 50 years ago, Bently Nevada now offers a comprehensive portfolio of hardware, software, and services specifically designed to address the special monitoring requirements of reciprocating compressors using our standard bearer 3500 and next gen Orbit 60 Series machinery condition & protection systems as well as our best in class System 1† software platform.

Today, Bently Nevada's reciprocating compressor monitoring solutions cover far more than just rider band wear with available measurements that provide advance notice on valve condition, pressure ring condition, pressure packing case condition, crosshead pin condition and many other important parameters on the health of your reciprocating assets..

As one of the oldest compressor designs, recips enjoy unique capabilities such as broad capacity control ranges, interstage cooling, the flexibility to efficiently compress gas regardless of mole weight or k value, and extremely high compression ratios. Consequently, they’re an ideal fit for selected applications such as hydrogen compression in the de-sulfurization process of many refineries and as part of low-density polyethylene production processes – to name just a few.

However, reciprocating compressors suffer from one very serious drawback: higher maintenance costs. In fact, compared to similarly sized centrifugals, recips can consume as much as five times the amount of maintenance dollars. A condition monitoring system designed to cover the most frequent causes of failure and routine wear in reciprocating compressors can help close that gap, bringing maintenance costs down to the levels associated with centrifugal compressors.

For many facilities employing reciprocating compressors, the machines occupy a critical role in the overall process flow – loss of a compressor often means a significant reduction in or loss of plant output. That lost production translates to very expensive downtime. Thus, maintenance costs are not the only driving factor that can help justify a monitoring system – lost production costs also factor heavily into the economic benefits a monitoring system can deliver.

A monitoring system for reciprocating compressors – as with any other type of machine – must first consider the types of failures and malfunctions that can occur, and then provide the specific measurements that can detect these problems. A Bently Nevada recip monitoring solution can identify many of the most critical malfunctions typical of reciprocating compressors. Including:

- Excessive Crankcase and Cylinder Vibration

- Excessive Main Bearing Temperature

- Excessive Combined Rod Load

- Faulty Cylinder Discharge Valves

- Leaky Pressure Rings

- Worn Rider Bands

- Excessive Piston Rod Flex

- Leaky Pressure Packing Case

- Excessive Bushing/Pin Clearance

- Excessive Crosshead Clearance

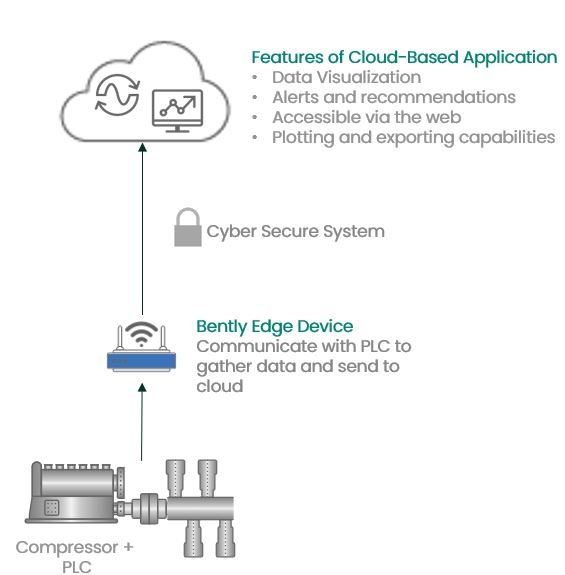

Bently Nevada can provide remote monitoring, advanced predictive diagnostics, and performance analysis for reciprocating

compressors with applications ranging from gas injection to booster stations with the ultimate goal of maximizing unrealized benefits.

With our remote monitoring recip service you get:

- Automated analytics—performance and diagnostics

- Subject matter expert data review

- Regular summary reports and coordination calls

- Intuitive HMI for data visualization and detailed analysis