We are Lufkin Gears and Allen Gears, Baker Hughes businesses.

We provide reliable power transmission technologies and services to solve the unique needs of every application across industry segments.

Overview

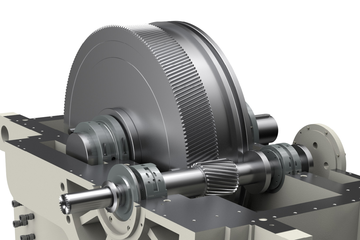

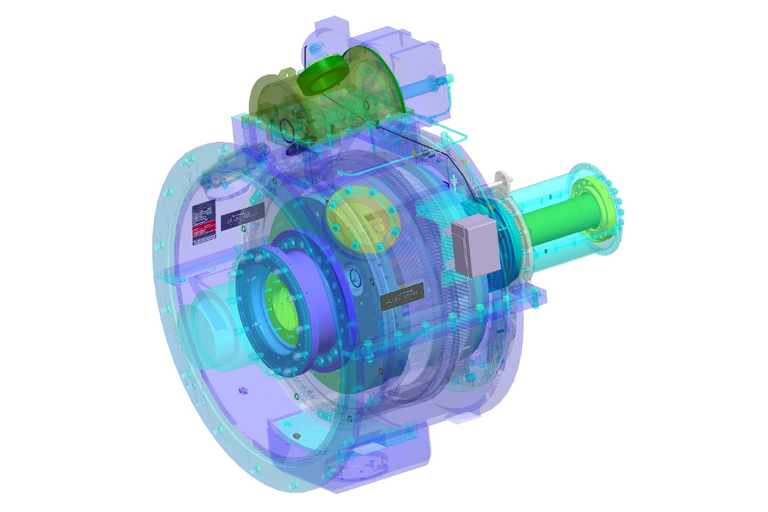

Our gearboxes transmit power from engines, servos, motors, turbines, and compressors in mechanical drive, turbo, industrial, and marine propulsion applications around the world. Our products and services are known for dependability and high performance, boosting uptime, and improving reliability while driving down maintenance costs.

Our engineers collaborate with customers to create solutions for the most demanding power transmission applications for rotating equipment. We draw on advanced materials, technologies, and manufacturing processes, to meet any challenge. Our portfolio includes high-speed parallel shaft, inline, helical, bevel, right-angle, epicyclic and integrally geared [LF2] configurations.

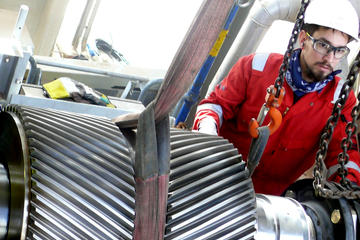

We're committed to providing high-quality equipment with competitive costs and delivery times. With 24/7 global support, our certified experts are ready to deliver unmatched service—whenever and wherever it's needed. In addition to servicing our own Lufkin Gears, Allen Gears, and Baker Hughes industrial gear products, we continue providing the same high level of service we always have for products from over 30 other manufacturers.

Product safety

A relentless focus on safety underpins our gearbox products. We're committed to acting with integrity and managing risk in epicyclic, parallel shaft, bevel, and helical gearbox design, manufacturing, testing, servicing, and monitoring.

Everyone takes responsibility for safety at Baker Hughes. Safety is entrenched in our core values — lead, collaborate, grow, and care — and is a vital part of everyday life at all our facilities.

The product safety culture in Turbomachinery & Process Solution is nurtured through our pillars:

- Accountability and commitment

- From reactive to proactive

- Governance

- Functional and process safety

- Customer value

Product safety is everyone's responsibility at Baker Hughes. It's entrenched in our core values to lead, collaborate, grow, and care; and it’s a vital part of every-day life at all our facilities worldwide.

Featured Video

Lufkin, Texas

Our flagship technologies were developed here nearly a century ago. Today, Lufkin designs and manufactures new units, and it hosts our Center of Excellence for repair, remanufacturing, and services—including drop-in replacements and upgrades for all power transmission needs.

Fougerolles, France

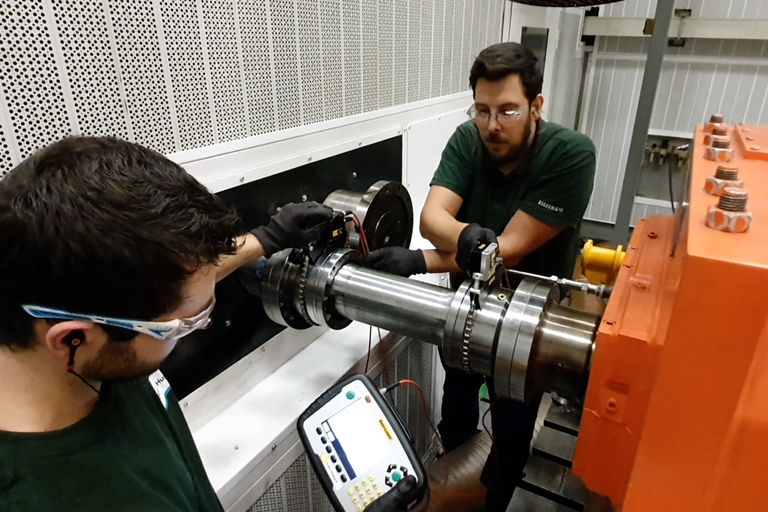

This advanced facility has been manufacturing high-speed and low-speed gears as well as couplings since 1965. The site also provides global design support, and repair services to customers in Europe, the Middle East, and Africa. We recently expanded its capabilities to manufacture our Allen Gears epicyclic gearboxes, and added machining capabilities and test stands, including one with a 2.5 MW driver.

Pershore, UK

At our Allen Gears Epicyclic Design and Field Service Center of Excellence, the engineering team designs bespoke gearboxes to the latest standards and provides upgrades and operational improvements to the existing epicyclic, helical and bevel gearbox designs and installed fleet. The field service team travels worldwide, on and offshore to support customers with routine overhauls, fitting of replacement parts, gear breakdowns, and fault finding on our own units, as well as gearboxes manufactured by other original equipment manufacturers (OEMs).

End-to-end solutions

- Custom-engineered gearbox solutions

- Customer collaboration from design to manufacturing

- High-speed and low-speed Lufkin Gears

- Allen Gears epicyclic gearboxes

- Civil and Military Marine propulsion gearboxes, including parallel, epicyclic, or bevel gears

- Parallel-shaft gears for 100+ MW

- Epicyclic gears for 35+ MW

- Combination parallel-shaft and epicyclic units

- Services on Lufkin Gears, Allen Gears, and units by over 30 other manufacturers

- Pools of gearbox-specialized field service engineers serving our customers worldwide

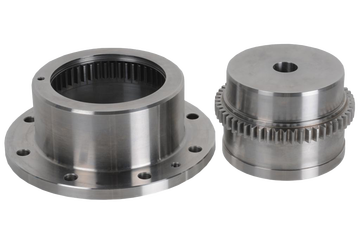

- Gear-type couplings

- High-performance bearings

- Custom gearboxes for test stands

- Multiple input shaft or output shafts/speeds

- Clutch integration

- Fixed-profile journal and thrust bearings

- Tilting-pad journal and thrust bearings

- Gearboxes for AC gearmotors/servos/electric motors

Blue Water

Medium & High Speed Diesels

Steam & Gas Turbine, & Elec. Motor Drives

Brown Water

Medium & Low Speed Diesels, and Electric Motor Drives

PetroChemical