No matter what the application or challenge, we provide a fully integrated solution to meet your needs—including motor, vessels, piping, supports and control panel. Our machines are designed for lower maintenance, operating, and capital costs while boosting performance of any operation.

A complete portfolio to fit every customer expectation

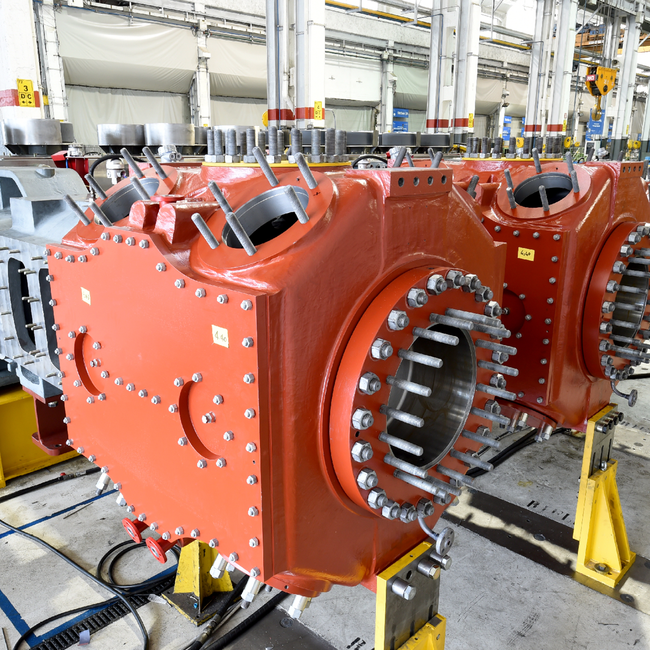

With decades of industry-leading performance, our API618 compressors live up to their reputation for low pulsation and vibration, ensuring exceptional efficiency, smooth operation, low maintenance, and low power consumption. Deployed in fullstream oil and gas applications, our proven modular design allows for up to 10 cylinders per frame, with a cylinder size of up to 1,250 mm.

Product safety

A relentless pledge to safety underpins the entire lifecycle of all our products. We're committed to acting with integrity and managing risk across our enterprise—in design, manufacturing, testing, servicing, and in monitoring our global installed fleet.

The product safety culture in Turbomachinery & Process Solution is nurtured through our pillars:

- Accountability and commitment

- From reactive to proactive

- Governance

- Functional and process safety

- Customer value

Product safety is everyone's responsibility at Baker Hughes. It's entrenched in our core values to lead, collaborate, grow, and care; and it’s a vital part of every-day life at all our facilities worldwide.

Our largest compressor ever

These compressors are the largest in our conventional reciprocating compressor portfolio, and the most powerful ever produced by our team so far. The 11x15 m footprint is larger than half a tennis court. It weighs over 330 tons, and is driven by 20-MW electric motors.

Baker Hughes Reciprocating Compressors Solutions for LDPE Platform

OA

HA

HB

HD

HE

HF

HG

1

2-4

2-6

2-8

2-10

2-10

2-10

435

2,120

5,520

10,400

28,700

34,600

66,820

117

145

236

322

607

1,140

1,980

800

1,000

800

700

800

514

514

SHM

SHMB

2-6

2-4

7,980

5,320

358

358

1,200

1,200

PH

PK

4-24

4-24 (12 cylinders per frame)

36,000

72,000

1,450

2,900

310

310