Highlights

Highlights

Benefits

- Assesses risk for single-run success and mitigation recommendations

- Optimizes milling parameters determined from data analytics models

- Optimizes in real-time for complete control of downhole milling conditions

Applications

- Casing Exits

Overview

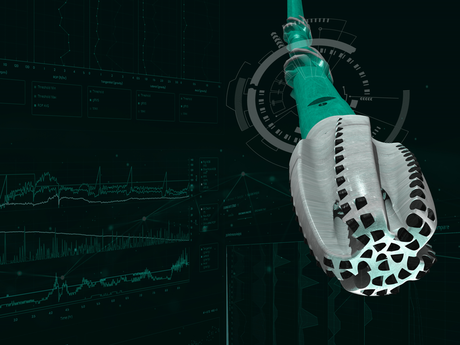

Get assured single-run window milling with reduced window drag, reduced vibration, and increased ROP for faster window milling and higher quality windows with the xSight analytics service for casing exits from Baker Hughes. xSight leverages well data analytics and an enabling cloud-based software application to add value through improved operational efficiency and consistent service delivery.

Casing exit operations provide a way to access a reservoir zone from an existing wellbore. However, milling a clean casing window in a single trip is not efficiently and consistently achieved. In more complex offshore wells, the failure rate could be as high as 20 percent, due to additional trips caused by failure of downhole equipment or suboptimal window quality that requires additional window polishing. Non-optimal milling parameters could lead to excessive vibration and other downhole milling dysfunctions –reducing milling efficiency, and in the worst cases, causing downhole tool failures.

The xSight service collects well data pre-job to conduct risk assessments and provide recommended milling parameters based on data analytics models, which have been trained from historical data sets and validated by performance improvement in the field. Data sets from historical jobs are used to develop predictive and prescriptive models. In this manner, well details, BHA details, downhole data, and surface data provide a holistic perspective on your casing exit operation. Accurate downhole measurements eliminate uncertainty and provide reliable input data for analytics modeling.

During operations, advanced analytics are used with real-time downhole measurements to enable data-driven decision making. Prescriptive analytics, coupled with real-time downhole measurements, ensure the best operating envelope while enforcing accurate control, combined with a corrective action roadmap during milling. This approach helps you optimize rotational speed (RPM), weight on bit (WOB) control, torque-on-bit (TOB), vibration, ROP, and window quality.

After the job, data is collected from the rig and downhole tools to enable post job analytics. This includes key performance indicators (KPIs) and data visualizations to describe job performance and to provide future recommendations, enabling real-time optimization and continuous improvement.

Contact us to learn how the xSight service can help you assess your next well to achieve clean casing windows in single trips, every time.