向全球提供先进的放射学和 CT 解决方案

Waygate Technologies 在全球范围内提供先进的射线照相和计算机断层扫描 (CT) 解决方案,以确保无损检测 (NDT) 的准确性和可靠性。我们的系统旨在让用户高枕无忧,帮助各行业在优化生产率的同时保持最高的安全标准。

威尔盖特科技公司拥有最广泛的 X 射线和 CT 技术,可满足各种行业需求。我们的解决方案包括传统移动胶片 X 射线、计算机化和数字 X 射线(CR 和 DR)以及二维和三维 CT 系统。这些创新技术使您能够以无与伦比的精度和速度进行检测。

您还可以信赖我们对 X 射线解决方案的支持。我们功能强大的射线照相和断层扫描解决方案可无缝集成到您的生产环境中。无论您是执行复杂的检查还是日常测试,我们高效可靠的系统都能帮助您降低成本、节省时间,并在生产过程的每个阶段生产出更安全、更可靠的设备。

我们做什么?

与其他无损检测品牌相比,我们能提供更多优质的无损检测解决方案。

各种三维计算机断层扫描 (CT) 和二维解决方案,适用于各种检测应用,从实验室中的亚微米分辨率纳米 CT 和精密测量任务,到使用线性气体踏板的高能 CT(用于高吸收率的大型样品),再到生产中的高通量 CT 检测。

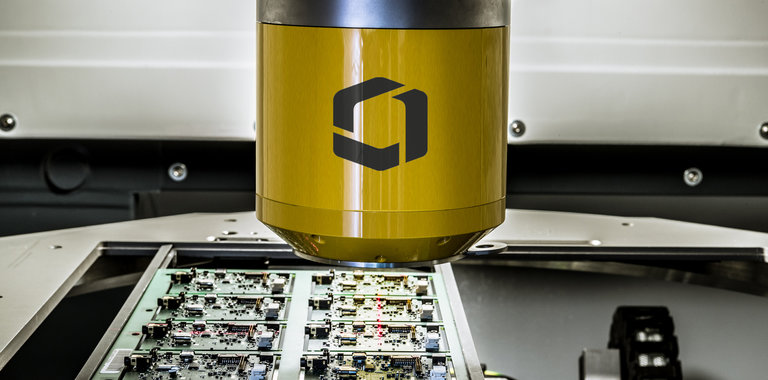

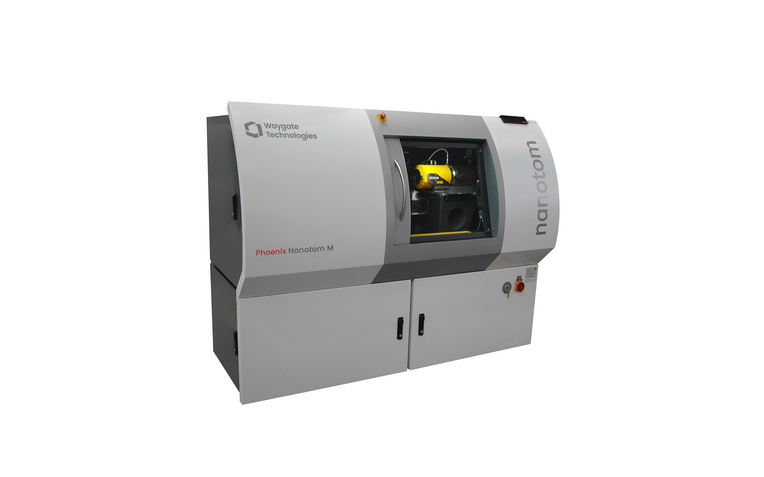

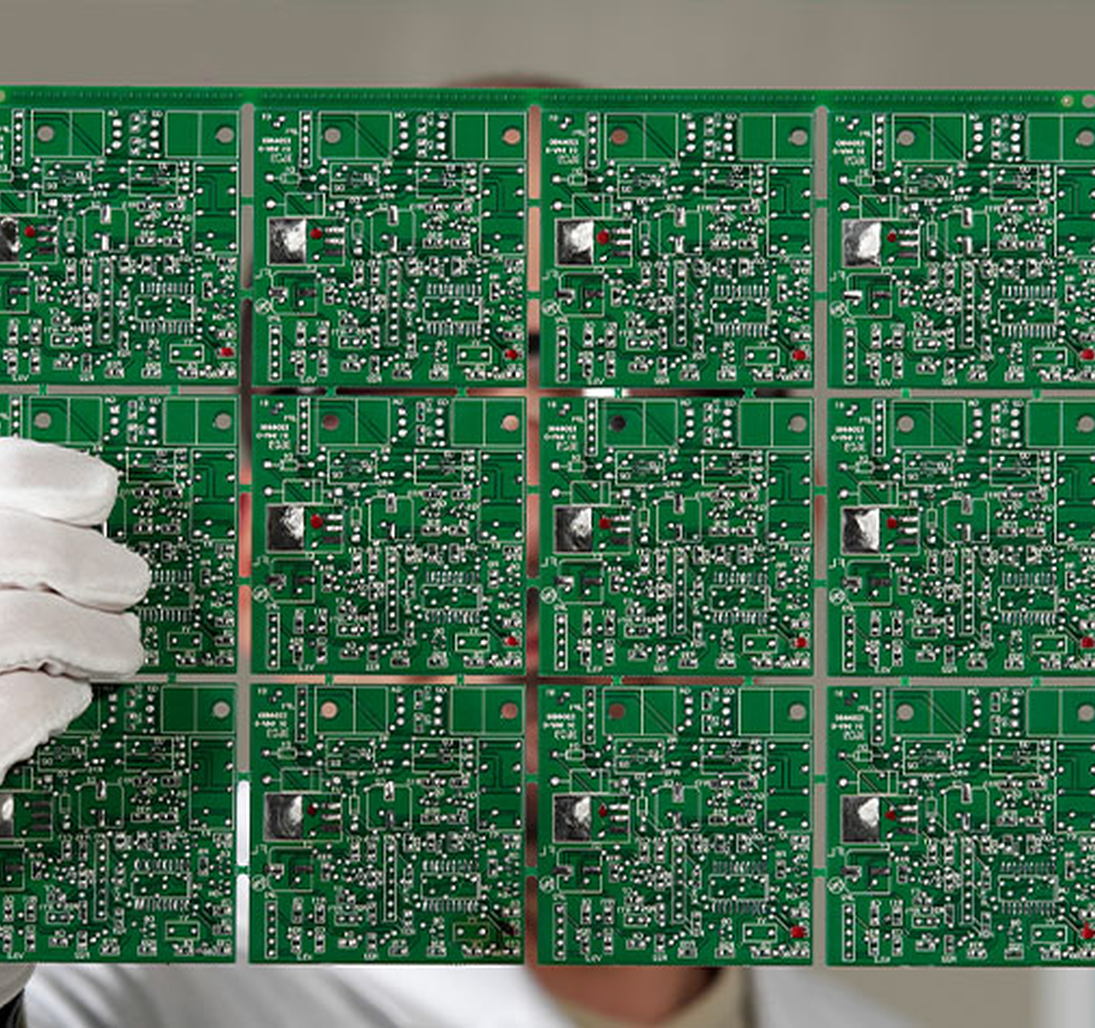

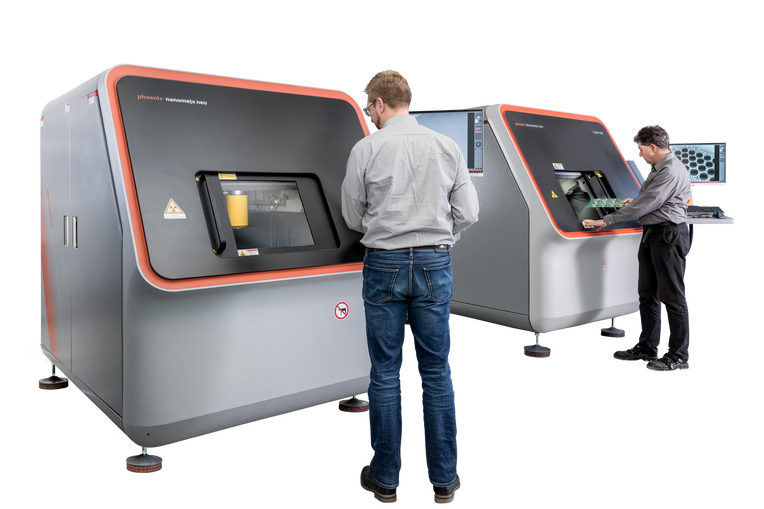

Wilgate Technology 的传统品牌 Phoenix 创立于 1999 年,是 PCBA 和 BGA 等微聚焦电子检测领域的先驱。自2002年发明第一台工业用纳米聚焦X射线管以来,威盖特已为半导体行业最苛刻的要求提供了卓越的检测解决方案,并为航空航天和汽车行业的大型部件检测提供了高通量CT解决方案。

特色

3D CT 检测和计量

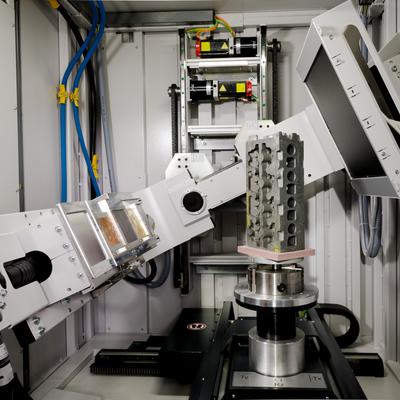

如果计算机断层扫描主要用于检查或测量,则必须将要检查的物体在 X 射线束中旋转 360 度。然后,可以根据数百张二维 X 射线图像重建 CT 体积。因此,所有的初级 CT 系统都有水平光束路径,这样样品就可以简单地固定在转盘上,并在 X 射线束中扫描。

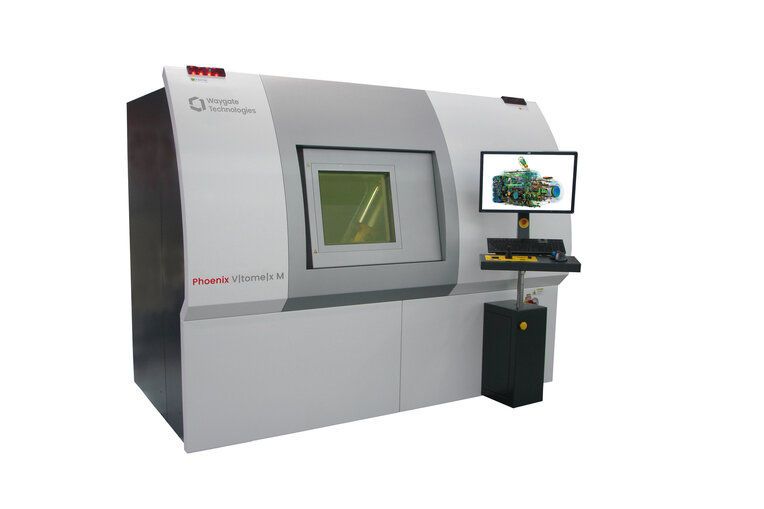

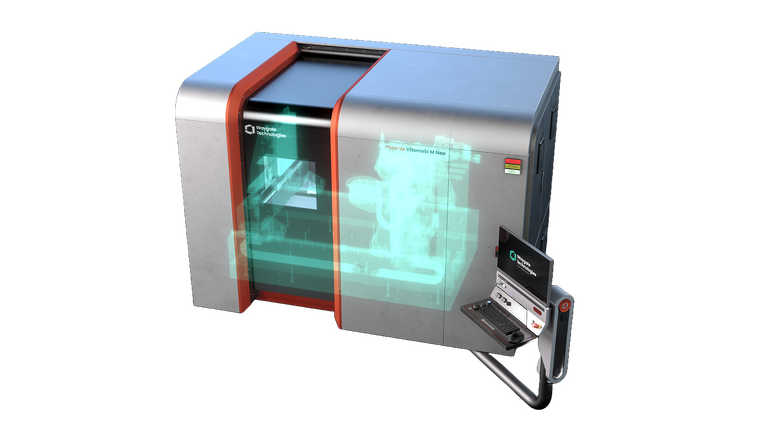

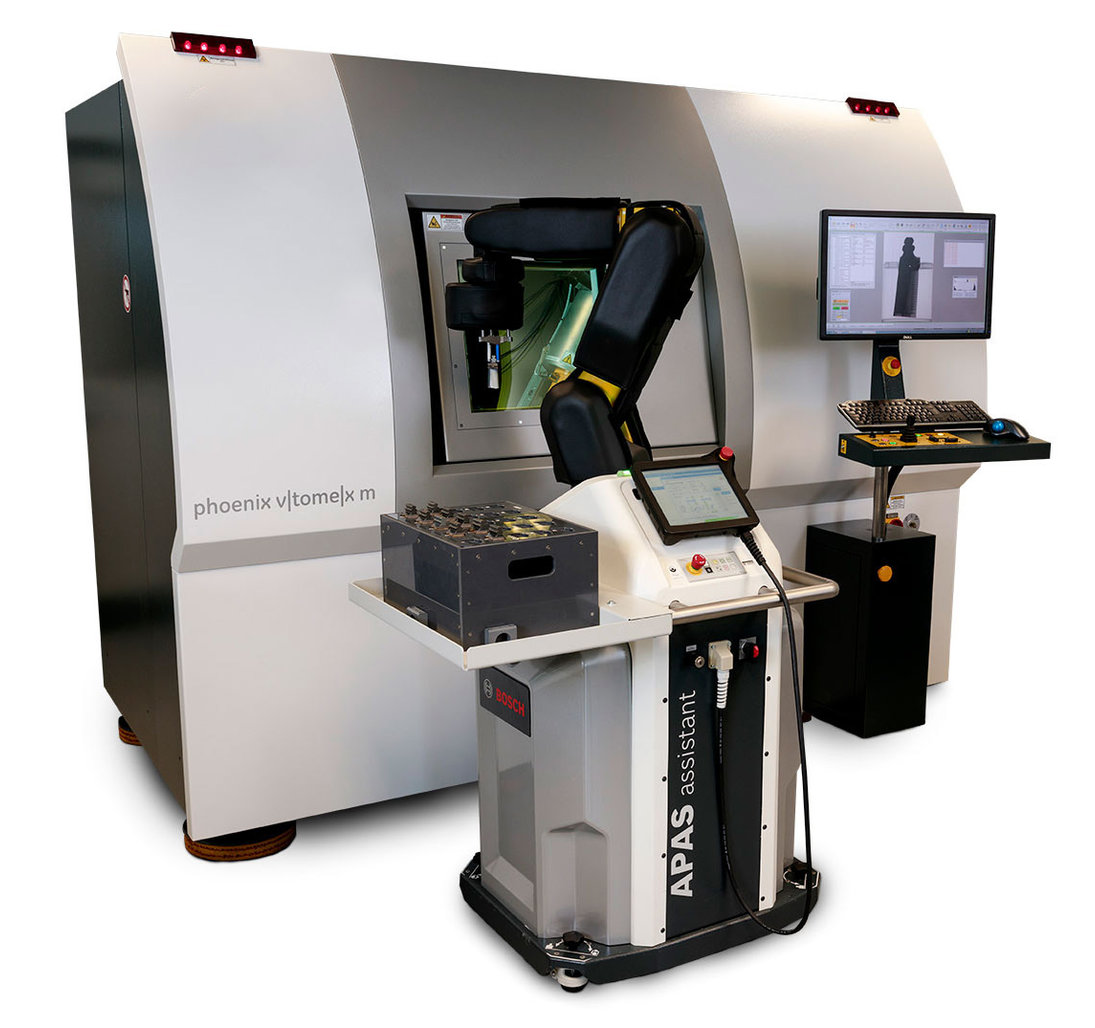

哪种系统是哪种应用的最佳解决方案取决于主要的计划应用:例如,如果系统不仅用于检测,还用于精密计量,那么它应具有特殊的校准和温度稳定功能,以及花岗岩机械手结构,并通过 VDI 2630 计量标准认证,如 Phoenix V|tome|x M 和 V|tome|x C,可用于对难以 X 射线检测的大型部件进行 X 射线检测。

特色

材料和样本量的影响

X 射线的吸收率一方面取决于被照射材料的厚度,另一方面取决于材料本身:元素周期表中元素含量越高,吸收率越低。因此,主要由碳、氢和氧组成的有机材料(如复合材料)易于辐照,而镁或铝铸件则较难辐照,但仍比吸收率高的钢铁部件轻。

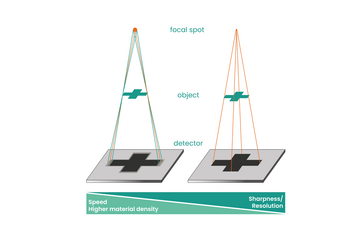

如果 X 射线管的焦斑尽可能小,使射线图像清晰地聚焦在探测器上,就能获得最佳的细节分辨能力。然而,所需的穿透能量越大,焦点就越大。因此,使用纳米或微焦 CT(Nanotom 最高 180 千伏,V|tome|x S 最高 240 千伏,V|tome|x M 最高 300 千伏)可以以极高的分辨率(最大细节检测能力小于一微米)扫描小型易辐射物体。对于较大的轻金属零件或中等尺寸的钢制零件,应使用中焦或微焦 CT 管,如 V|tome|x C(最高 450 kV)。对于直径达近 2 米的大型工件或穿透大量钢材的工件,Power|scan HE 不仅拥有 450 千伏的微焦 X 射线源,还拥有 9000 千伏的线性气体踏板。

特色

我们的射线检测和工业 CT 设备

为什么选择威曼技术

120 多年的经验

威盖特科技公司在无损检测(NDT)领域有着深厚的历史积淀,在为多个行业提供可靠、优质的检测解决方案方面拥有超过一个世纪的丰富经验。

灵活的工业 CT 扫描

Wilgate Technology 的 CT 系统具有检测小型部件和大型组件的灵活性。我们的解决方案采用双管配置,扫描直径可达 2000 毫米,可为航空航天和汽车等行业提供精确的结果。

效率最大化

Waygate Technologies 的优质 CT 解决方案可将检测时间从数小时缩短至数分钟,同时不影响检测质量。Scatter|correct 技术和 Dynamic 41 数字探测器等创新技术可为您的检测提供精确、高分辨率的结果。

适应复杂环境的解决方案

从移动 X 射线设备到先进的三维 CT 系统,威盖特技术公司提供各种射线和 CT 解决方案。这些强大而高效的工具可无缝集成到生产工作流程中,提供精确的检测,有助于节省时间和降低成本,同时确保各行业的最高安全和质量标准。

射线照相检测 (RT)/X 射线检测属于无损检测 (NDT) 的范畴,是一种通过 X 射线穿透目标样品进行检查的方法,在此过程中可突出显示材料密度的偏差,这可能是需要处理的缺陷信号。

射线照相法使用 X 射线和伽马射线生成目标样品的射线图像,使技术人员能够观察到材料厚度的任何变化、内部和表面缺陷,甚至装配细节(如焊缝、接头、连接器),以确保生产的最高质量和安全水平。

射线检测(RT)的主要优点之一是,它能为给定的目标样品生成永久的硬拷贝(以 X 射线胶片为例)扫描记录。在数字传感器/探测器的例子中,记录是数字的,可以本地或远程存储,不需要与 X 射线胶片相关的处理和存储需求。

什么是 X 射线?

X 射线是一种高能电磁辐射,波长在 1nm 到 1 pms 之间,大约比光波长小 1000 到 1,000,000 倍。由于能量高,X 射线能够穿过吸收普通可见光的材料。

一般来说,X 射线检测系统包括一个辐射安全外壳、辐射防护柜、线性排列的 X 射线管和 X 射线探测器。用户可通过一个可远程控制的操纵装置将样品置于射线束内。最终的 X 射线图像显示在显示器上,供计算机处理图像。此外,X 射线系统还可配备电子程序控制装置,实现样品的自动检测。X 射线图像根据材料密度的差异显示物体特征。

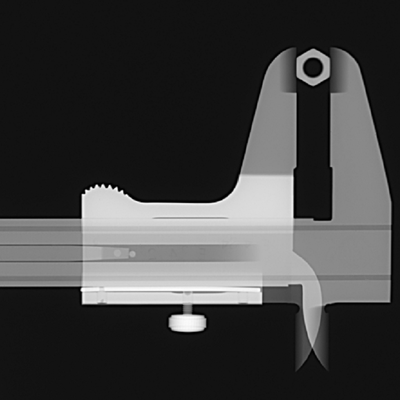

部分 X 射线光谱在穿过物体时会被吸收。物体越厚或密度越高,被吸收的 X 射线就越多,无法通过。穿过物体的 X 射线会撞击探测器,在探测器上形成 X 射线图像。根据入射光线的强度,图像由不同的灰度组成: 物体较厚的部分或密度较高的材料(如铁、铜和铅)比密度较低的材料(如塑料、纸张甚至空气)看起来更暗。

然后在暗室中对胶片进行冲洗--就像一般的照相胶片一样--胶片所捕捉到的不同程度的辐射会表现为不同的白色和黑色。未被目标样本吸收的 X 射线会导致射线探测器曝光。这些区域将显示为黑色。由于吸收率较高或材料密度较大,吸收率较高的区域会显示为浅色。

这样,目标样本中均匀密度因气孔、裂缝或错位等缺陷而发生变化的区域将显示为深色线条,从而使熟练的技术人员更容易检测到。

射线检测 (RT) 主要用于管道、压力容器、储存容器、管道和结构焊缝的焊缝检测和分级。

实际上,凡是用焊缝连接在一起、需要承受某种压力或负荷的物体都需要进行射线检测,以确保焊缝的完整性。

其他检测对象包括机加工部件、金属板或管壁(尤其是在需要考虑腐蚀问题的情况下)。

陶瓷、轻金属铸件或添加剂部件(如航空航天和汽车工业中使用的部件)也要通过射线照相术进行检测。

射线检测(RT)可通过 X 射线或伽马射线实现。X 射线是通过 X 射线管产生的,而伽马射线则是通过引入放射性同位素产生的。

这些辐射源使用的能量比电磁波高得多。

由于射线照相术检测涉及电离辐射,因此必须确保传达和遵守适当的安全准则,以防止辐射。

与其他形式的无损检测相比,射线检测(RT)具有多种优势。 其中包括

可以用胶片或数字方式保存扫描记录

能够观察整个样品

对缺陷的识别水平更高

对操作员和检查员的技能要求较低

训练有素的放射技师不仅能通过 RT 准确定位缺陷,还能识别缺陷的类型、大小和位置。

说到缺点,显而易见的是您要处理的是相对危险的材料,一旦暴露在辐射中,就会对健康造成长期的不良影响。

此外,传统的 RT 解决方案,尤其是基于胶片的解决方案,需要大量时间才能生成可用图像,从而延长了生产周期。

这也是当今许多机构采用数字探测器的原因之一,因为数字探测器可以避免传统 X 射线胶片所需的处理时间。

X 射线发生器

X 射线发生器在真空中通过电子发射产生 X 射线。在击中目标材料后,X 射线被发射出来并射入目标样品。在样品中,X 射线会根据目标材料和密度被吸收或散射。穿过目标样品后,光子会被探测器(如 X 射线胶片或数字探测器)捕获。

数字转换

如今,许多机构正在从传统的胶片射线照相术向基于数字传感器的解决方案转变,以节省时间、降低成本并提高整体无损检测性能。

超声波检测(UT)和涡流检测(ECT)是当今无损检测领域的两种主要方法,因为它们具有更高的信号质量、灵活的探测选项,而且不涉及放射性材料或危险化学品。

UT 依靠超声波探测目标样品并检测其中的任何偏差,而 ECT 则是通过目标样品中的电子电流产生磁场,从而突出显示材料密度和厚度偏差。

ECT 和 UT(尤其是相控阵超声波测试)都比 RT 安全得多,在某些应用中还可以节省时间。

便携性也是 ECT 和 UT 解决方案的一大特点,因为它们往往更小、更易于操作,因此适合在现场使用,而 RT 则更适合实验室或生产线应用。尽管如此,目前有几种便携式 RT 解决方案可以成功部署到现场。

计算机断层扫描可提供被检查物体的三维空间图像。

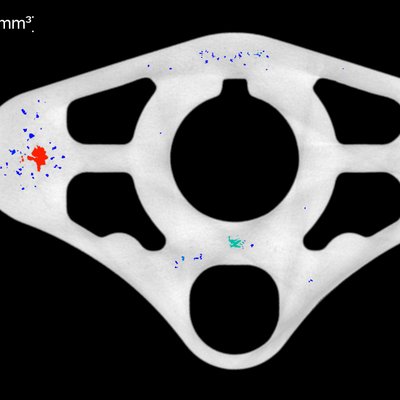

CT 图像将不同的材料显示为不同的灰色(或不同的颜色)。要生成三维图像,需要围绕一个旋转轴(360°)拍摄大量二维 X 射线图像(或切片)。

然后使用复杂的重建算法将这些 X 光图像重新格式化为结构的体积表示(三维)。