With proven and best-in-class reliability and availability, our technology and teams have what it takes to support LNG industry challenges

We’ve been committed to LNG for over 30 years

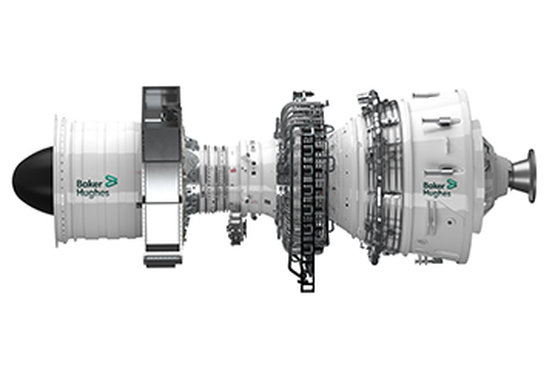

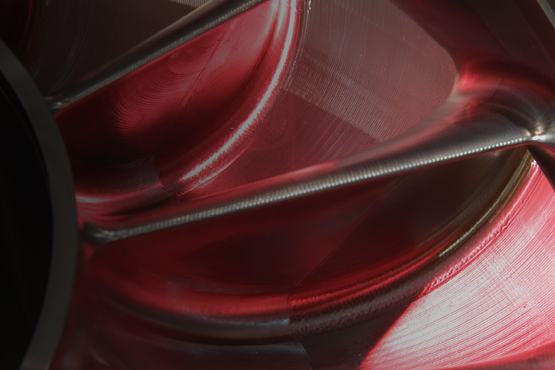

There are currently 60 LNG plants in operation or under construction around the world that rely on our turbomachinery — which drives over 440 MTPA of global installed capacity. We are the most referenced OEM for LNG plants, including large gas turbines and main refrigerants compressors.

A history of industry firsts

In 1989 at Woodside, we were the first LNG production and export supplier to use a double-shaft gas turbine train for LNG. In 2008 at Qatargas, we carried out five simultaneous major LNG facility overhauls that cut outage time in half. In 2017 for Petronas, we installed core machinery for the first floating liquefied natural gas (FLNG) facility. In 2019, we were the first to use large motors for fully electrified e-LNG in Freeport, Texas. In 2023, we were selected by Petronas to supply the most efficient simple cycle gas turbine LM9000 for the Sabah LNG offshore project.

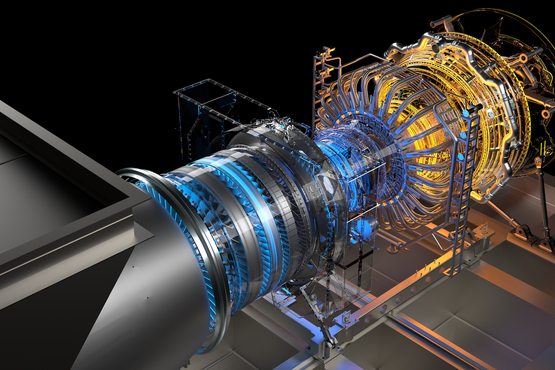

A unique portfolio serving the LNG industry across all needs

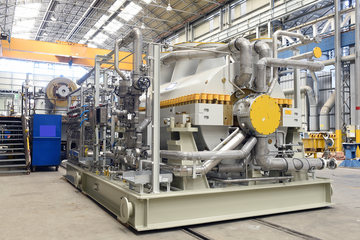

We have tailored solutions to meet all LNG industry needs. Our experience spans across all geographies and climate conditions, from gas turbine-driven to electric motor-driven solutions, from traditional stick-built to modular designs, from onshore to offshore, and with all the LNG process licensors.

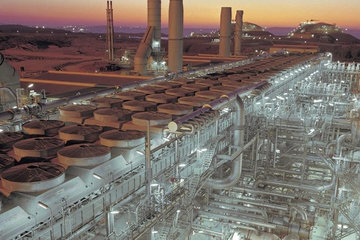

From massive to mega: the Qatargas LNG trains that changed the industry

|

Summary Following up on the three compression trains installed at Qatargas 1, we were asked a few years later to support a series of major expansion projects for Qatargas and Ras Laffan LNG Company—designing and installing a total of six new liquefaction "mega-trains" with an unprecedented production capacity of 7.8 mtpa each. Since then, we've continued evolving our gas turbine and compressor train technologies, and honing our service approaches to keep our customers, and the industry overall, moving forward. Read the full case study today. |

Supporting 440+ million tons of capacity

Our combination of innovative technologies, flexible service models, performance-based service agreements, and extensive data analysis from our installed LNG facility fleets and from LNG shipping, show we have a proven record of improving LNG plant and LNG trade performance. With best-in-class reliability and availability, our power generation plant technology teams have what it takes to support global LNG projects.