Highlights

Highlights

Benefits

- Back off premium threaded casing with high-torque breakout capacity

- Reduce thread damage by eliminating over-torquing of tool joints

- Increase flexibility by using with tubing as a workstring

Applications

- Back off casing at a known or desired coupling location

- Run as an alternative to a casing patch during a casing repair

Overview

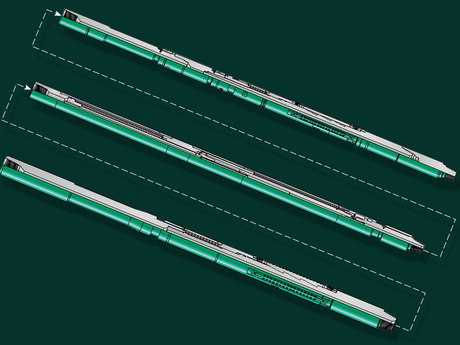

Eliminate blind casing backoffs during your casing repair jobs with the hydraulic casing backoff tool from Baker Hughes. As an alternative to running a casing patch, the casing backoff tool gives you assured casing backoff at a known or desired coupling depth and location.

The typical hydraulic casing backoff tool assembly consists of one stand of drill collars, mechanical collar locator, lower anchor section, backoff section, upper anchor section, pump out sub, several stands of drill collars, and workstring. Normally, the casing is cut and pulled, then the hydraulic casing backoff tool is used to remove the stub.

The casing backoff tool includes several features that improve the efficiency of your casing backoff operations.

- Back off premium thread capacity with the tool’s high torque breakout capacity

- Withstand torque output and make firm bites into the casing’s ID with anchor sections with special carbide insert slips

- Maintain full casing integrity and reengage with new casing string by ensuring an intact threaded connection

- Eliminate restricted ID after repairing casing by maintaining original wellbore

- Minimize well site requirements by requiring no left-hand workstrings for backoff

- Reduce thread damage and deformed connections by eliminating over-torqueing of tool joints

- Increase flexibility by using the tool with tubing as a workstring

Contact us today to find out how the Baker Hughes hydraulic casing backoff tool can help you back off casing efficiently.