Highlights

Benefits

- Enhanced performance in complex intervals

- Expanded operating envelopes

- Improved stability with less vibrations and smoother torque responses

- Increased ROP and improved hydraulic efficiency

- Predictable, reliable performance

Applications

- Complex drilling environments, complex directional profiles, and lithologies

- More powerful BHAs and rigs with increased energy demands

- Extended-length laterals

- Formations causing lower ROP or multiple bit runs

Overview

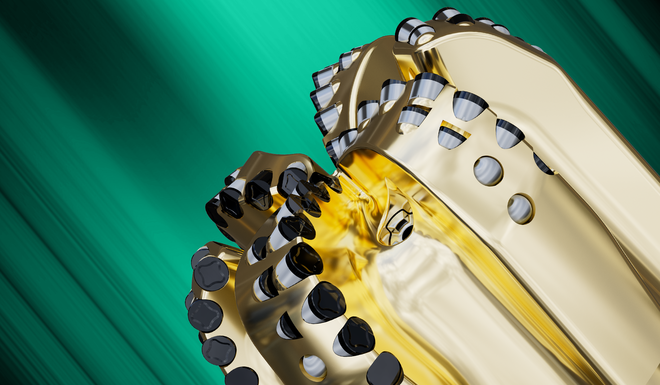

PermaFORCE™ elite PDC drill bits are designed to enhance rate of penetration (ROP) for faster drilling, while maintaining durability to complete the interval. These bits reduce well construction costs by improving drilling performance in applications where traditional PDC designs compromise performance for durability.

Make fewer trips with fewer compromises

PermaFORCE elite PDC drill bits deliver both enhanced stability and durability—improving drilling performance in complex intervals and challenging formation transitions.

- New PDC cutters demonstrate increased abrasion resistance and thermal stability with greater resistance to impact damage

- Uniquely shaped PDC technologies deliver greater durability and maintain a sharp cutting edge—expanding the operating envelope in challenging formations

- An improved stability window protects the cutting structure from premature damage in a wider variety of operating condition

Improve drilling speed and efficiency

PermaFORCE elite PDC drill bits are designed to drill faster through different formations and destroy challenging rock types more efficiently than traditional PDC drill bits. Cutting structures can be tailored to an application to deliver a truly versatile design that:

- Increase ROP potential and drilling efficiency

- Improves stability response during formation transitions for reduced vibrations

- Enhance hydraulic efficiency with expanded junk slot volumes and optimized nozzle placement

Enhance reliability under extreme conditions

PermaFORCE elite PDC drill bits are designed to perform reliably under extreme operating conditions and can be run confidently in the most challenging PDC applications.

We design and engineer our PermaFORCE bits using the proprietary Baker Hughes 3D Tetrahedron™ bit drilling simulation software. This allows designers and application engineers to:

- Analyze, predict, and optimize PDC designs by creating digital twins of the bit and drilling environment

- Deliver a solution with fewer design iterations

New matrix materials enhance the strength and wear resistance of the PermaFORCE drill bit body—improving performance under extreme conditions without compromising bit reliability.

Contact your local Baker Hughes representative to learn how PermaFORCE elite PDC drill bits can extend drilling efficiency and reliability in your most challenging formations.