Highlights

Highlights

Benefits

- Flow rate up to 15,000 m³ per hour

- 3-4% higher efficiency through dedicated options

- High reliability tailored for remotely controlled operations

Features

- Robust and compact casing design tailored for heavy duty full rating applications

- Hydraulic design which fits to pipeline profile

- Reverse hydraulics available to be operated as hydraulic power recovery turbine (HPRT)

Applications

- Main and booster water/oil pipeline

- Ammine and solution processes in oil and gas

- Cooling water and generic industrial high flow transfer

Overview

The Baker Hughes family of BB1 pumps includes three product designs to meet API610 requirements:

- DVS: single stage between bearings for heavy-duty service

- BFD: two stages between bearings for heavy-duty service

- DVE: single stage between bearings for medium duty

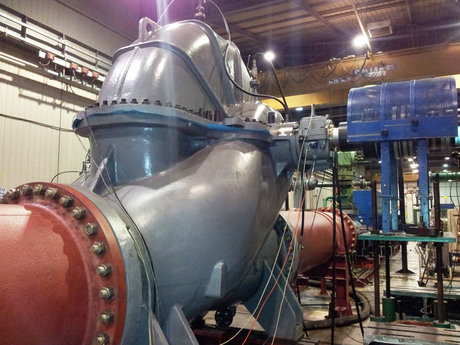

Referenced worldwide in pipeline and heavy-duty process applications, our DVS and BFD centrifugal pumps were redesigned in 2010 to deliver up to 3-4% higher efficiency and a flow rate of up to 15,000 m3 per hour. Most commonly coupled to an electric motor, they significantly reduce consumption costs and CO2 emissions in power generation. These robust units provide the pumping power needed for economical production and transportation of heavy oil and bitumen, which have particularly challenging viscosities and API gravities. The flexible, compact DVS and BFD designs are a great fit for applications with gas turbine drivers.

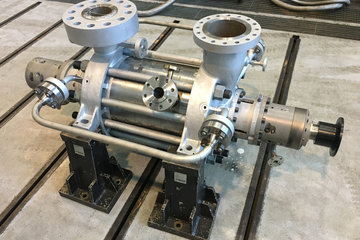

Our DVE pumps are designed to cover generic high-flow circulation in oil and gas and other industrial applications, sharing the hydraulic benefits recently introduced in the Baker Hughes BB1 portfolio. Our engineers can deliver any client’s requirement to match the installation layout, spanning from schematic and modular power-generation arrangements to restricted spaces aboard FPSOs.

Key design features

The DVS/DVE design is horizontal, single stage, double suction, double volute, and horizontally split between bearings. Key features include suction and volute channels that are specially shaped to maximize uniform flow while reducing recirculation and friction losses. The advanced impeller design also minimizes vane and disk friction losses, and optimizes blade loading.

These pumps have passed a stringent qualification process for high-value operational and environmental benefits. Running at full capacity for a year, one new DVS centrifugal pipeline pump can save the energy equivalent to the electricity consumed annually by over 200 U.S. homes, while pumping the volume equivalent of an Olympic-size swimming pool every 16 minutes.

All sizes of our BB1 units are fully tested in house—at full power in dedicated rigs—with all running parameters controlled in real time controlled to validate project design performance.