Highlights

Highlights

Benefits

- Optimizes uptime, runlife, pump performance, and oil production

- Reduces operating and maintenance costs

- Protects ESP system equipment and allows for multiple deployments

Applications

- ESPs deployed via coil tubing

- Installation as part of a retrievable ESP assembly

- TransCoil rigless-deployed ESP production operations

Overview

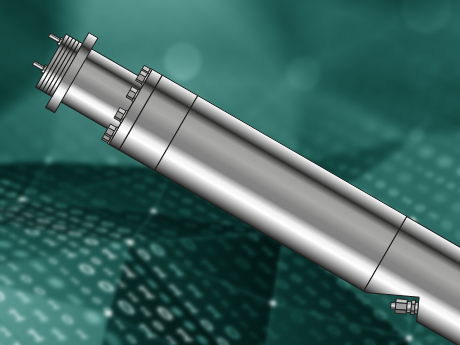

Get reliable downhole monitoring of your coiled tubing-deployed electrical submersible pumping (ESP) system with the Zenith™ E-CTD ESP gauge from Baker Hughes. Designed for the TransCoil™ rigless-deployed ESP system, the Zenith E-CTD gauge records and transmits accurate, real-time measurements of production operations. With this information always available, you’ll have a fast, appropriate, and confident assessment of your well’s production and artificial lift system performance.

Get ease of installation and reliable monitoring

The Zenith E-CTD gauge is easily installed above the motor with a connector linking the three-phase ESP power to the motor. The gauge is connected electrically via a downhole inductor assembly.

The TransCoil system also includes an intake pressure and temperature assembly below the pump, which connects to the gauge using 1⁄4-in. pressure and temperature lines.

All Zenith E-Series gauges are calibrated during manufacture and retain this calibration on board, eliminating the requirement for dedicated key at the surface.

Ensure real-time data visualization in multiple interface options

Clearly and quickly monitor downhole performance with the Zenith E-CTD gauge’s various data acquisition options:

- The Zenith interface unit (ZIU) interfaces the gauge signal to a RS232 or RS485 Modbus output for use on a drive or SCADA remote terminal unit

- The Zenith surface panel (ZSP) provides on-screen data charting, alarms and trips, analogue and data (Modbus) communication signals

Deploy the Zenith E-CTD gauges as part of the Sabio™ ProductionLink™ artificial lift monitoring solution. By applying the power of the industrial internet, this solution helps you visualize well, field, and operation-wide data for smarter deployment of resources. You’re also assured more insightful decision-making to predict issues with lift systems, optimize production, and reduce operating costs.

Contact us today to learn how the Zenith E-CTD ESP gauge can enhance oil recovery from your well.