Reducing CAPEX and system complexityWater injection is a widely used technique to support pressure to the reservoir and enhance oil recovery. With abundant seawater available offshore, it is ideal for injection applications, but needs to be treated first. Traditionally, seawater has been treated in large-scale, heavy, topside processing plants. The Baker Hughes approach to subsea seawater treatment is to eliminate the conventional chemical clean-in-place (CIP) unit by operating the filtration membranes at lower fluxes. This greatly reduces CAPEX and system complexity, while maintaining system robustness and extending filter life. Our seawater treatment system allows seawater to be treated and injected subsea, eliminating the need for heavy, high-pressure risers and flowlines—and reducing the weight of topside equipment by more than 90%. This cost-effective solution is especially attractive in brownfields and tie-ins.

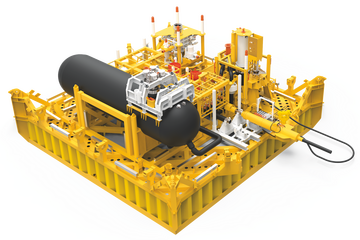

Tailored water quality and injection capacitySeawater treatment involves the removal of solids that can cause blockages or fracture the formation, as well as sulphates and other divalent ions, which can cause scaling and souring when interacting with either formation water or sulfate-reducing bacteria in the reservoir. Our subsea seawater-treatment systems are based on a modular concept that can be tailored to provide exactly the level of water quality and injection capacity you need, including standard raw seawater treatment, sulfate removal and desalination. The systems are also all-electric, so they only require a power cable to run them, and use strategically positioned subsea water-injection pumps to inject the treated water around the reservoir—optimizing water flooding and improving oil recovery.

Extended product lifeAll our seawater treatment systems are designed to be highly reliable and use many of the technologies found in typical topside facilities, including ultra-filtration (UF) and nano-filtration (NF) membranes. The UF and NF membranes are run at low flux to extend their life, and we avoid the regular use of the aggressive chemicals that are normally needed to clean them and recover their performance.

Reduced maintenanceThe UF membranes are backwashed regularly with sodium hypochlorite, which is produced subsea in an electro-chlorinator unit, ensuring that the membrane modules only need to be retrieved once every five years for maintenance. In standard raw seawater treatment, the water is filtered to remove any solids or micro-organisms using a coarse filter that removes particles down to 30 microns. The water can then be treated using ultraviolet radiation—an alternative to chemical disinfection—to kill bacteria, prevent biofouling and reduce the risk of microbiologically-induced corrosion in the injection system.

Superior three-step processOur approach to subsea sulfate removal is a refinement of raw seawater treatment that involves a three-step process before the water reaches the required quality for pumping into the injection well. The first step essentially follows standard raw seawater treatment. Then, the treated water passes through a series of UF membranes, where particles and even bacteria down to a nominal size of 0.02 microns are removed. In the third and final step, the water passes through a series of NF membranes that remove sulfates and other divalent ions, with a small boosting pump compensating for the pressure drop between the NF and UF membranes.

Tuneable salinity optionAn additional module with reverse-osmosis membranes can be added to the sulfate-removal system to remove salt from the seawater and enable tuneable salinity for injection. This provides the potential to increase recovery slightly by removing more residual oil from the reservoir. This module is placed in parallel with the NF module and the rest of the process is virtually the same as that used for sulfate removal.

Features and benefits include:

|

Overview

Get in touch with an expert.

Your request has been submitted.

Thank you for your interest. A specialist will be in touch with you shortly.