Overview

Proven technology

Ranging from the first centrifugal compressor for the fertilizer industry to the most powerful high-pressure offshore units, we have installed over 5,000 centrifugal and axial compressors since 1960. Our technologies revolutionized large liquid natural gas applications in the 1990s. Today, we continue to invent and evolve as we develop new types of compressors.

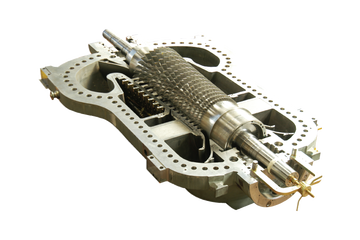

Comprehensive portfolio of centrifugal compressors

Our portfolio is in continuous evolution to cover the energy industry's most demanding requirements for pressure, flow rate, gas compositions, and plant arrangement. Thanks to close collaboration with our customers, and our focus on innovation, we have a unique history of success in the LNG sector with all processes and drivers.

Thanks to close collaboration with customers and our focus on innovation, we have a unique history of success in LNG, natural gas, and petrochemicals.

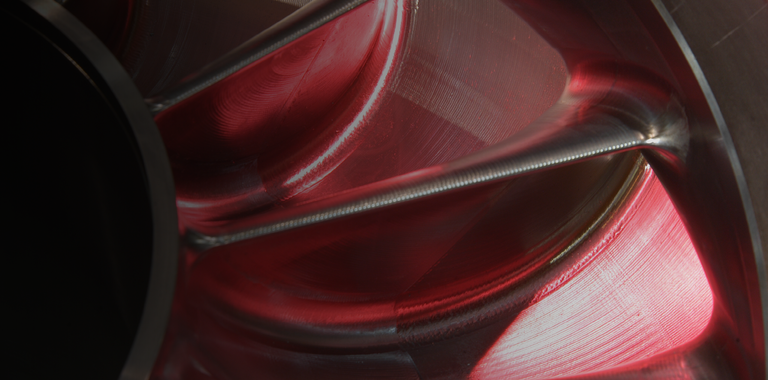

Driving increased performance

Our experts continually improve our compressor product line through extensive research and development and optimization, advanced design capabilities, and modern manufacturing techniques — enabling ever-higher performance.

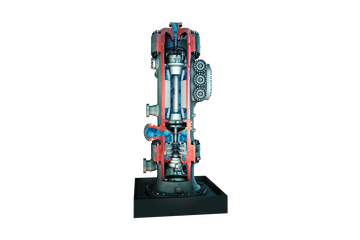

Fully integrated solution

Our compression trains can be optimized for any solution, and are delivered fully packaged with plug-and-play modularization. We have all the technologies, resources, expertise, and global capacity to deliver full trains including balance of plant and auxiliaries—as well as full integration with all electric motors, electric grid and customer assets.

Product safety

A relentless focus on safety underpins the lifecycle of all our products. We’re committed to acting with integrity and managing risk across our centrifugal air compressor enterprise — from design, manufacturing, testing, and servicing, to monitoring our global installed fleet of compressor units.

This product safety culture is nurtured through our pillars:

- Accountability and commitment

- From reactive to proactive

- Governance

- Functional and process safety

- Customer value

Product safety is everyone’s responsibility at Baker Hughes. It is entrenched in our core values — to lead, collaborate, grow, and care — and it’s a vital part of everyday life at all our facilities.

Featured Video

- In-line

- Back-to-back

- Intercooling

- Side stream

- Double flow

- In-line

- Back-to-back

- Intercooling

- Side stream

- Double flow