Overview

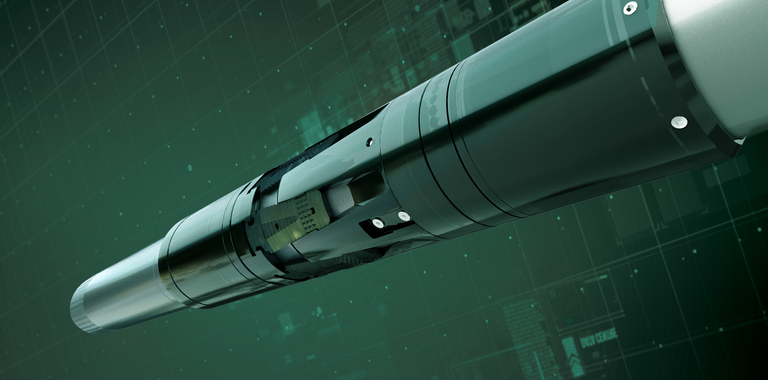

Liner hangers from Baker Hughes give you proven means to hang the liner in your previous casing string. With your liner reliably deployed to its setting depth, you can confidently cement the liner while in tension and provide a solid bottom against which to set a liner top packer.

Select from both mechanical-and hydraulic-set hangers with options for ultrahigh hanging capacity, high bypass, and rotation while cementing. Liner hangers can be deployed in moderate environments of 10,000 psi (689 bar) and up to 300°F (149°C) to extreme high-pressure, high-temperature (HP/HT) and high-pressure, low-temperature (HP/LT) conditions requiring a pressure rating up to 15,000 psi (1,034 bar) and 450°F (232°C).

The mechanical-set CMC liner hanger gives you high flexibility and reliability in most combinations of liner-to-casing sizes. The hanger’s low-profile slips lower the risk for damage during deployment while a staggered slip design maximizes bypass flow area.

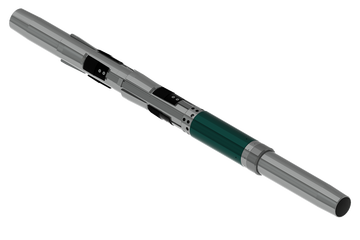

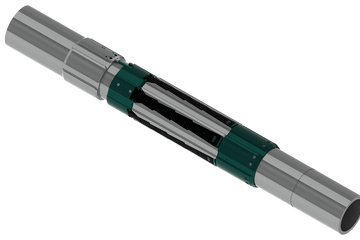

The SDD™ hydraulic-set liner hanger gets your liner to depth in rough formations. With a rugged, single-piece body design and heavy-duty slips, the SDD withstands hours of heavy rotation and reliably sets with a high load capacity.

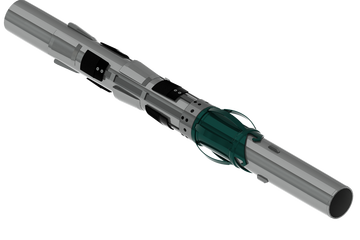

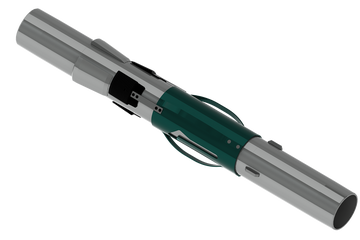

The FLEX-LOCK V™ liner hanger lets you effectively reach desired setting depth in extreme downhole conditions such as heavy drilling fluids, high solids content, and liner rotation. The latest version in the FLEX-LOCK-style hanger family, the FLEX-LOCK V offers a slip seat wedge profile and slip rail design for increased resilience to solids packing off and for greater hanging reliability.

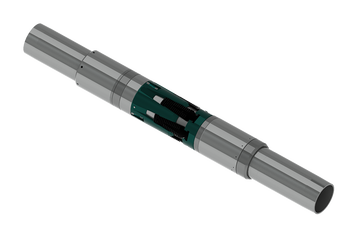

The HMC™ hydraulic-set liner hanger sets by hydraulic pressure—without reciprocation or rotation—to reliably hang your medium-length liners. And with its staggered slip design, you’re assured a large bypass area for ease of deployment and free circulation.

The Hyflo II™ and Hyflo III™ liner hangers give you an economical liner hanging solution in your light-to-medium applications. With their streamlined design and the flexibility of mechanical or hydraulic setting, these hangers deliver a reliable completions solution in a range of well applications.

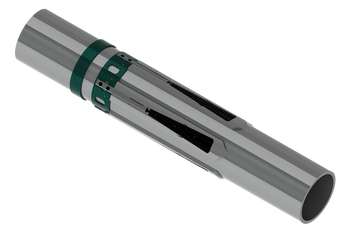

The SlimX™ liner hanger gives you assured deployment in your tight-clearance wells. With a robust body and streamlined design, the SlimX hanger is ideal for applications requiring high load capacity and minimal annular clearance.

Contact us to learn how our liner hangers can get your liner to its desired setting depth—quickly and cost effectively.