Gas lift mandrels from Baker Hughes deliver proven performance and reliability for any completion application. Whether your installations are on land or offshore, in the frigid arctic or desert heat, you get highly engineered, high-quality mandrels to meet your most demanding well conditions.

Solutions for any service

Our mandrels are designed to meet your specific deployment and performance demands.

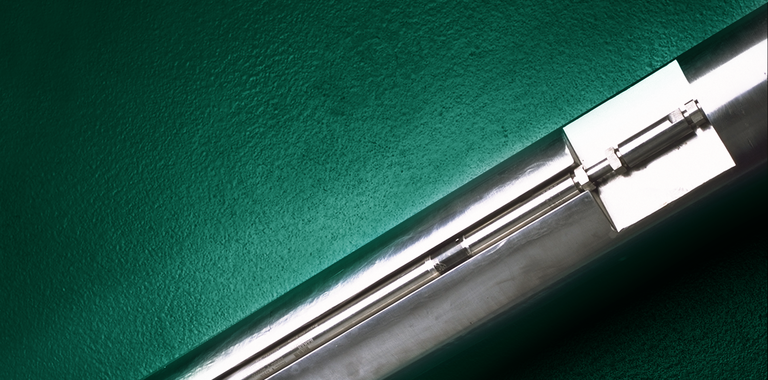

Our tubing retrievable gas lift mandrels are installed as an integral part of your production tubing for gas lift, chemical injection, or other special applications.

Our side pocket mandrels give you added flexibility by allowing valves to be installed and removed by wireline. Save time and money by eliminating the need to pull the mandrel or the tubing to repair or replace a valve.

Designed with engineering and quality processes developed over years of dedicated effort, our side pocket mandrels include several enhanced features to meet the most demanding requirements.

- An oval body design option includes both machined and forged pocket designs that are typically used in dual string completions requiring side clearance

- A round body design option is available for high-pressure environments or applications requiring special clearance

- Many designs offer full-tubing inner diameters (IDs) to allow normal wireline operations through the tubing string

- Each mandrel features a standard side pocket profile to receive gas lift valves, chemical injection valves, circulating valves, dummy valves, shear orifice and dump kill valves, and other related flow control devices

- Different pocket porting configurations are available for applications such as casing flow, chamber lift, and waterflood applications

Contact us to learn how gas lift mandrels from Baker Hughes can help optimize your gas lift system for maximum production.