Highlights

Highlights

Benefits

- Engineered-to-order solutions, optimized to offer exceptional reliability and long life

- Our gearboxes draw on decades of engineering expertise, innovation, and support

- Manufacturing and service support in North America and Europe

Features

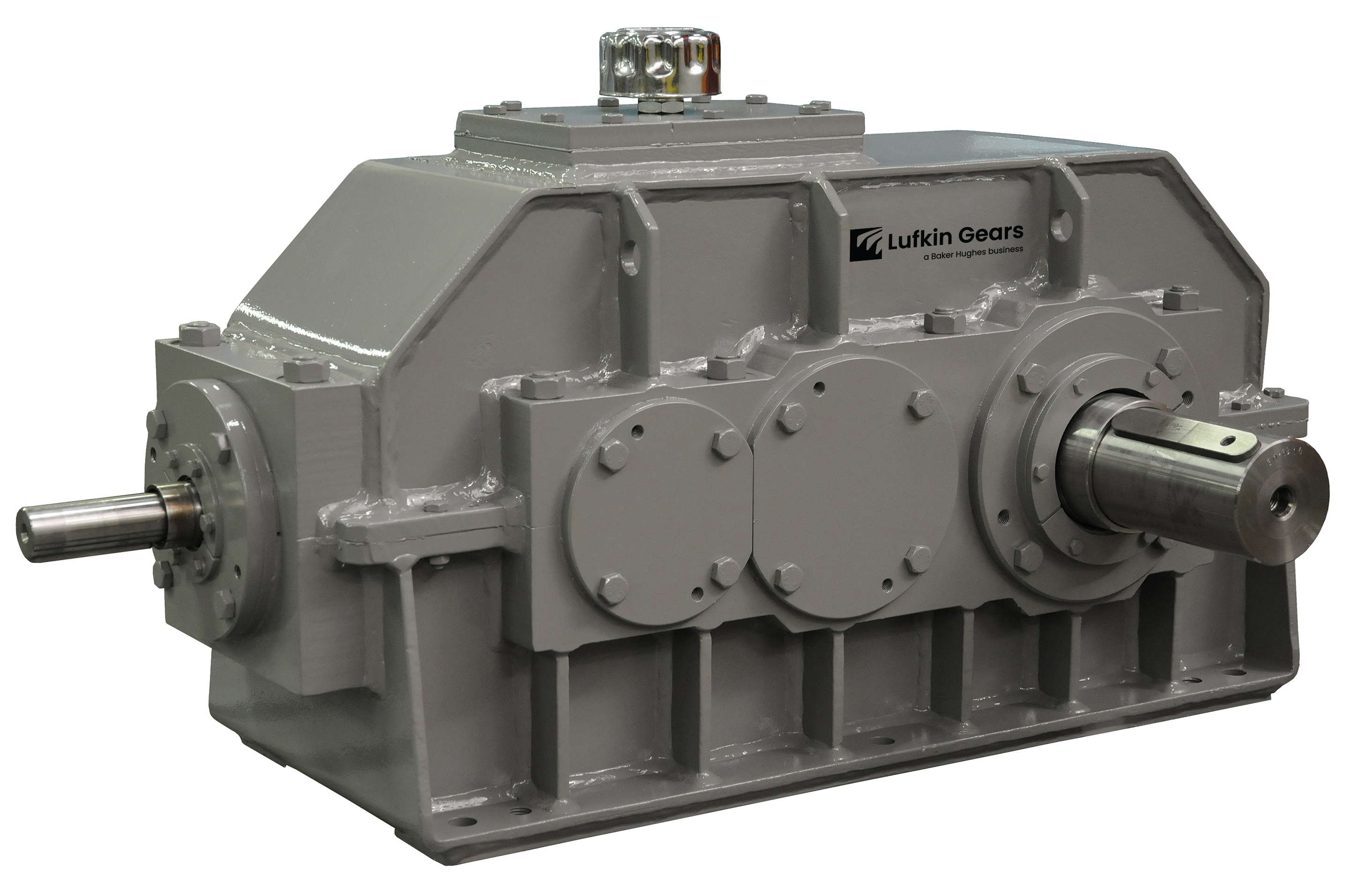

- Purpose-built to exact customer specifications and industry-specific standards

- Robust designs with rigid case construction for durability in demanding applications

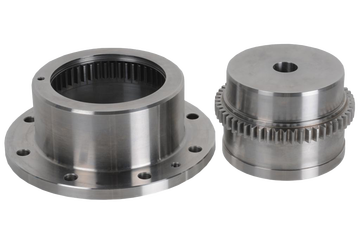

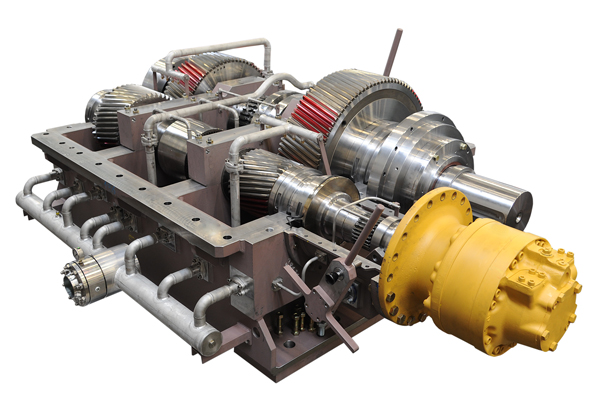

- Multiple input and output shafts and accessories available

Applications

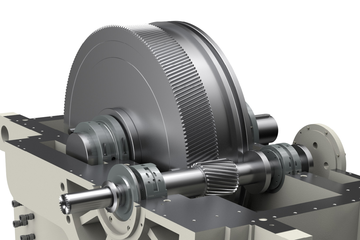

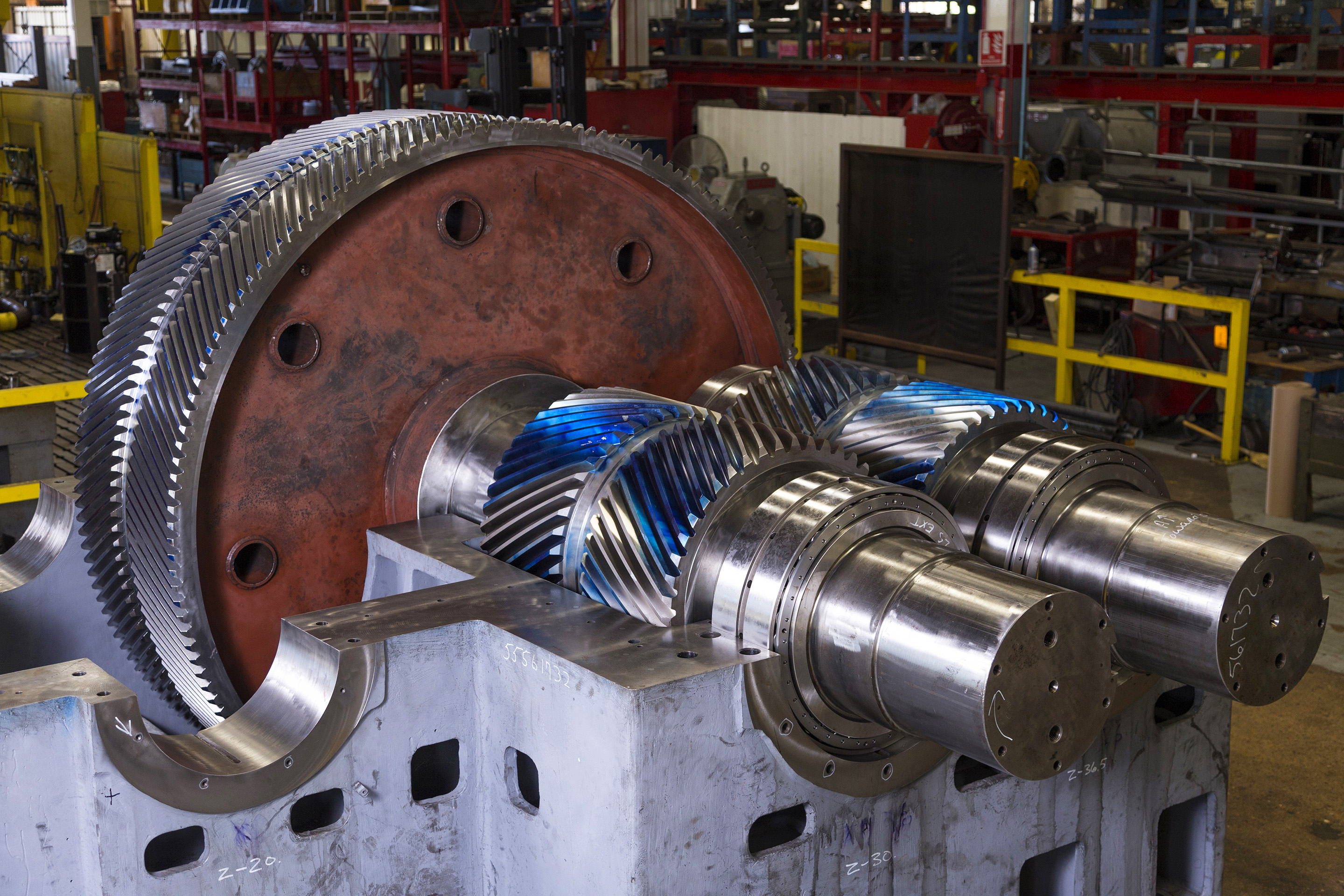

- Single and double helical gearing using carburized, through-hardened, and nitrided teeth with precision-ground finishing

- Conservatively sized anti-friction or journal bearings for longevity

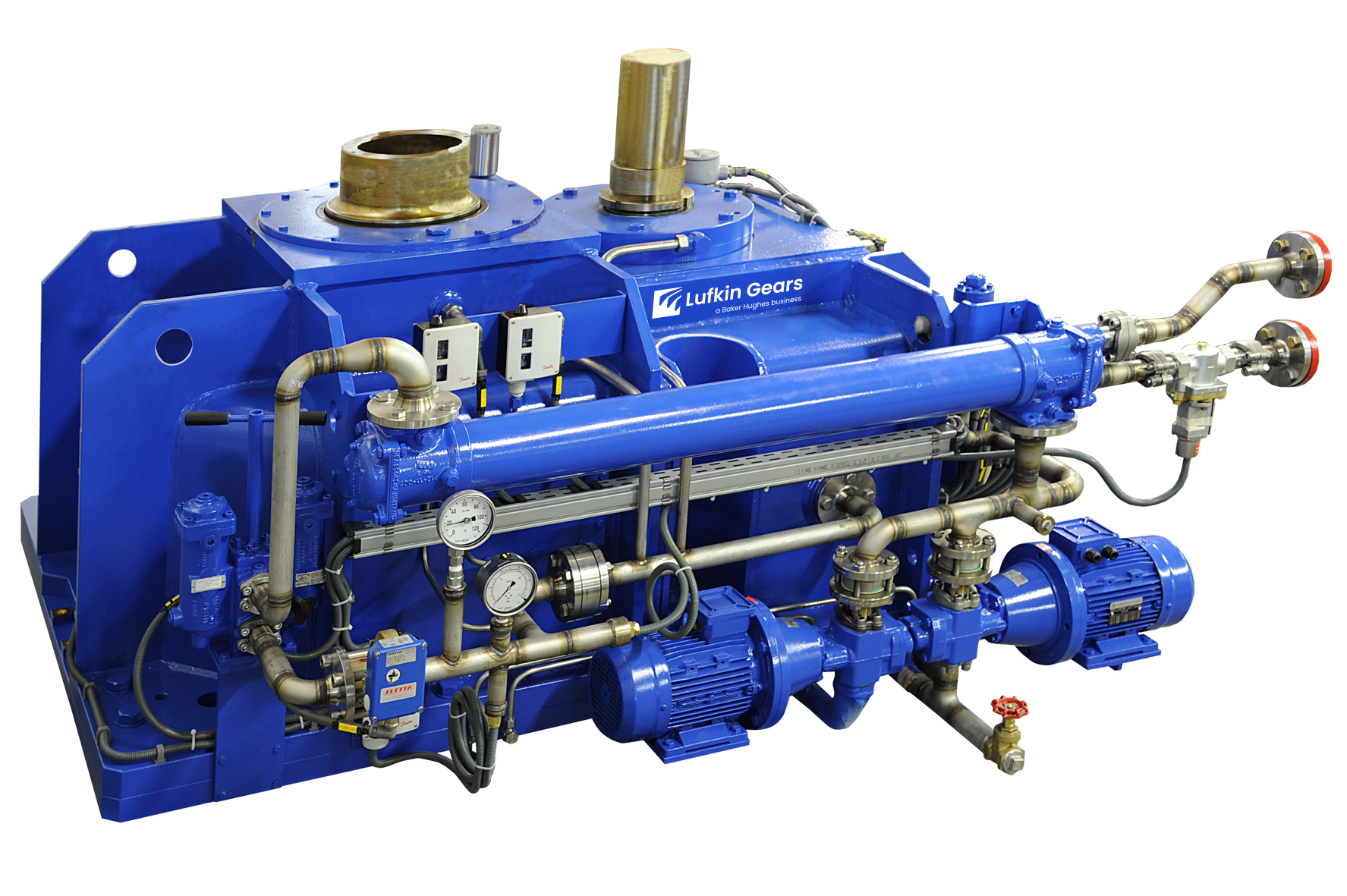

- Integrated lubrication and instrumentation monitoring systems

Overview

Overview

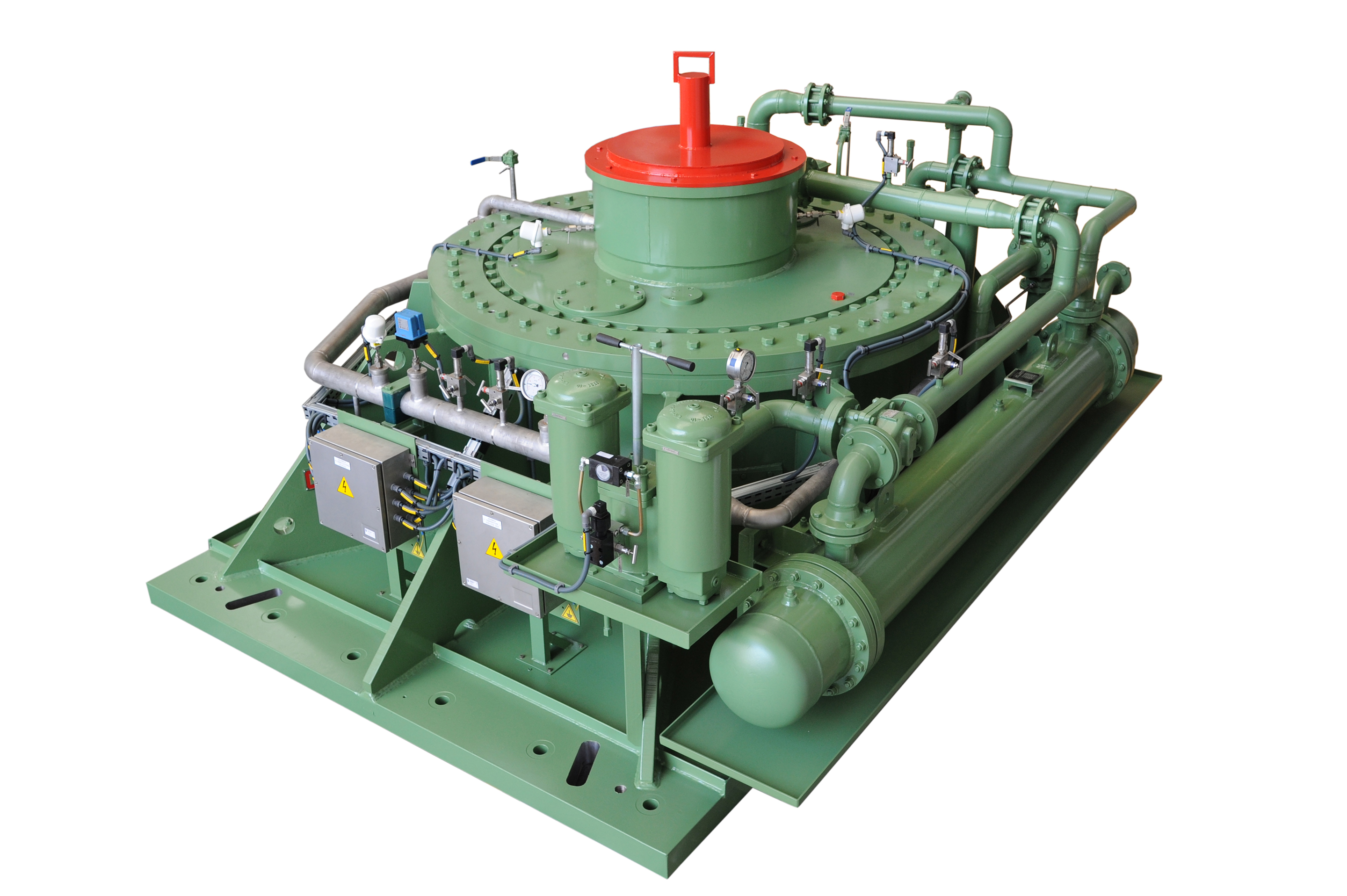

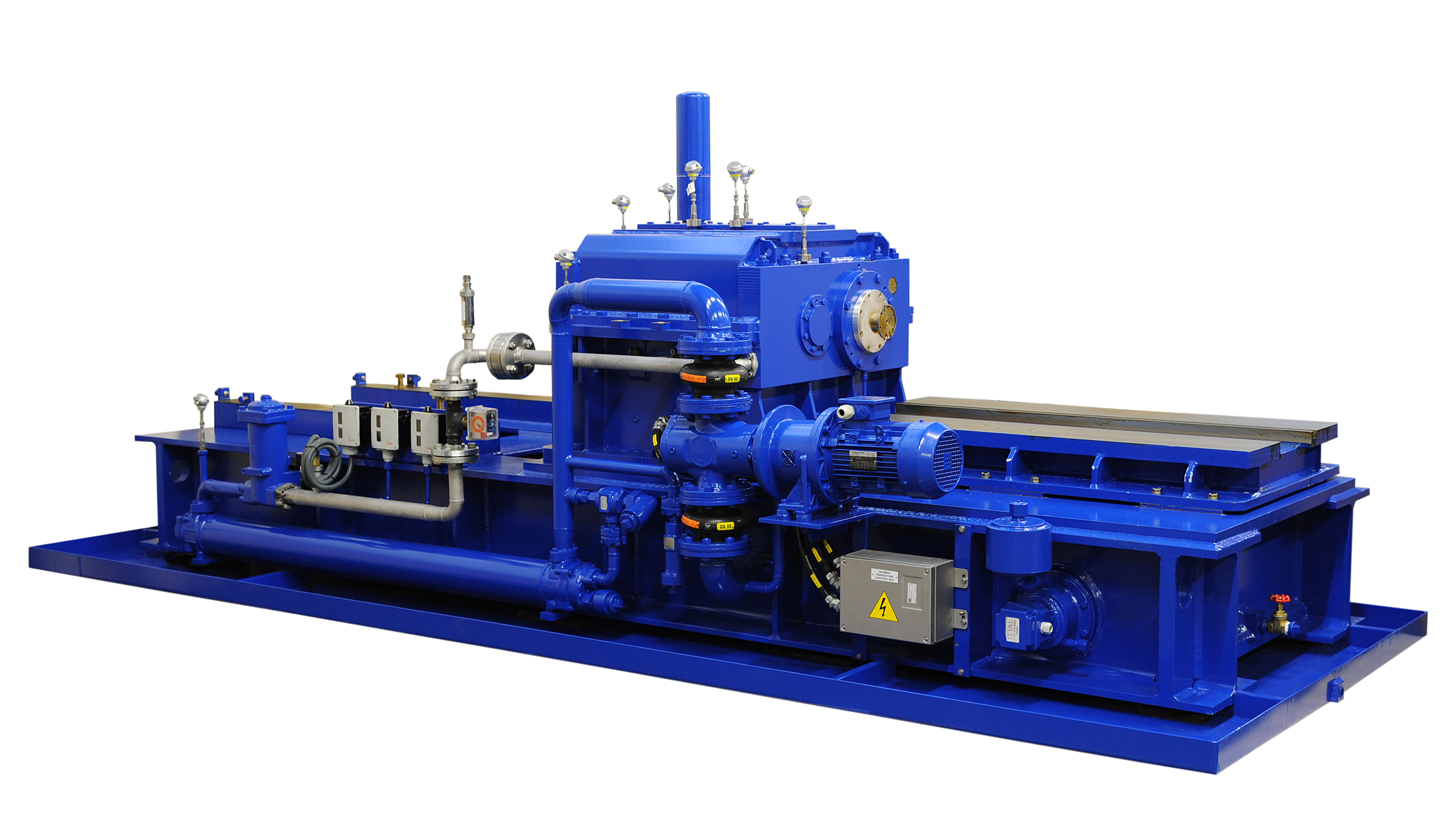

Lufkin Gears low-speed, increasing, reduction, and parallel shaft gears are widely used with turbines, pumps, electric motors, generators, and compressors in many heavy industries and are renowned for reliable performance in the most demanding applications.

Using state-of-the-art design, we adapt to a variety of industry standards such as ISO, DIN, API, and AGMA, and our gear drives can also be ATEX-certified on request. Each gearbox is individually factory-tested at full speed under no-load or loaded test regimens.

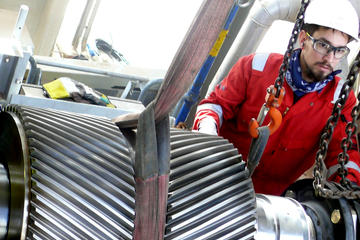

A wide range of options such as upgrade and repair services are available, including full lubrication systems, continuous monitoring vibration and temperature sensors, as well as clutch and anti-rotation systems. We also offer drop-in replacement gearboxes following customer and application requirements to reduce downtime and avoid disruptive on-site modification.

Rubber and plastics

Tire producers around the world count on heavy-duty Lufkin Gears speed reducers for batch mixers and mills. We also specialize in custom applications including extruders, calendars, and roll mills. Lufkin Gears products are well known by rubber and plastics productions for their value and reliability.

Sugar

We've supplied Lufkin Gears multi-stage speed reducers to the sugar industry for more than 50 years. Many of our mill drives and cane knives are still in operation after a half century of service. We're also able to provide customized solutions such as multi-stage parallel shaft and planetary gears for mills and cane diffusers to meet any sugar production needs.

Pumps

Lufkin Gears low-speed gearboxes are used in centrifugal pump, dredge pumps, booster pumps, and positive displacement applications in oil, gas and industrial plants around the world. We adapt to industry standards like ISO, API, and AGMA while providing optimized solutions according to each project's unique requirements. Over the years, the Lufkin Gears brand has been the industry standard for dependability in critical pump gearbox applications.

Iron and steel

Lufkin Gears technologies are used worldwide on hoisting equipment, rolling mills, and winders. With thousands of units in our installed base, we have the expertise to keep any steel production line rolling. Drawing on broad experience across the metals industry, we specialize in upgrading existing gears to increase throughput and reliability.

Cement and asphalt

Lufkin Gears products are designed to be the most reliable and robust equipment for applications such as mills, grinders, presses, conveyor drives, and kiln drives. Our units are available in parallel shaft and planetary configurations, single stage or multiple stages.

Mining and aggregate

Our technologies are well known for keeping production moving under the most demanding conditions. We provide proven solutions for crushers, pumps, slew drives, bucket wheels, blendomat, conveyor drives, and many more applications. Our gearboxes are available in horizontal or vertical parallel shaft, angular shaft, or planetary configurations with custom accessories and monitoring equipment to meet every need.

Extruders and mixers for plastics and polymer processing

We have a long history of supplying extruders and mixers for the plastics and polymer industry. Our experts regularly provide specialized gear solutions with single or twin output shafts in corotating or counter-rotating applications with integral thrust bearings.

Hydro power

Our products are known around the world for reliability in hydro-electric plants. Our low-speed Lufkin Gears parallel-shaft increasers are used for vertical, pit or KAPLAN turbine applications; and our Allen Gears epicyclic products are powering some of the largest geared hydro plants in the world. Our trusted brands give around-the-clock piece of mind to power generation plants.

Oil drilling

Lufkin Gears single-speed and multi-speed power swivel gearboxes are the industry standard for reliable performance in oil extraction. These are some of the most demanding gearing applications in very harsh environments. When downtime is not an option, onshore and offshore drilling operators count on the Lufkin Gears brand to deliver.

Test stands

Our test stand services are used by customers worldwide to prove performance, increase production, or develop new technology. We provide custom testing solutions in civil and military operations for aerospace, electric motors/engines, pumps, generators . With more than 400 proven test bench applications, we have the experience to meet any highly technical testing requirements.

Nuclear

With over 500 references and installations, Lufkin Gears and Allen Gears are key brands throughout the nuclear industry. We have decades of proven performance and reliability in reactor building, auxiliary building, cooling systems, and hoisting equipment around the world.