Overview

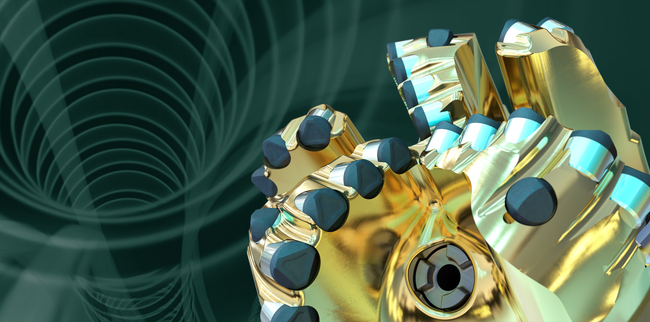

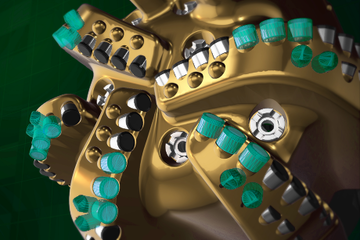

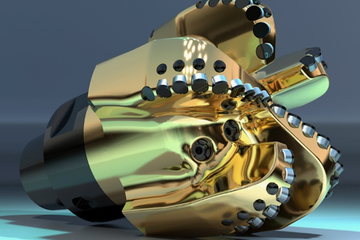

Whether it is the Dynamus™ extended-life drill bit or Talon™ Strike PDC drill bit, or our new PermaFORCE™ elite drill bit, our selection of PDC drill bits achieve maximum speed and efficiency to lower your drilling cost.

The Dynamus extended-life drill bit lets you reduce trips while using the most robust drilling equipment available. It prevents damage that shortens the life of your BHA components by smoothing out lateral vibrations and its new high-strength body extends bit life in extreme operations.

And with the Talon Strike bit, you get consistent performance, competitive pricing, and fast response times in soft to medium-hard formation toughness and moderate application complexity.

PermaFORCE™ elite PDC drill bits are designed to enhance rate of penetration (ROP) for faster drilling, while maintaining durability to complete the interval. These bits reduce well construction costs by improving drilling performance in applications where traditional PDC designs compromise performance for durability.

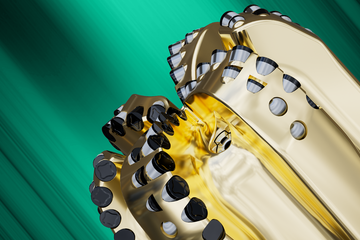

Optimize your PDC bit performance with shaped-cutter technology

The wide application range for PDC bits requires unique PDC cutter technology to get the most drilling performance in each application.

StabilisX™ shaped-cutter technology provides maximum durability for interbedded formations that can cause heavy impact damage.

The unique geometry of Shockwave™ shaped-cutter technology balances efficiency and durability and works well in interbedded formations that cause thermal damage and chipping.

CryoCut™ shaped cutters reduce friction while drilling through hard, abrasive formations where thermal damage and chipping are the dominant failure modes. These cutters provide the high efficiency and wear resistance because an engineered relief deflects cuttings away from the working edge of the cutter to keep the cutter cooler for longer.

Apex™ shaped-cutter technology provides a traditional point loading approach by distributing more weight to a smaller portion of the rock. This allows the cutter to penetrate ductile formations and maximize drilling rates.

Prism™ shaped-cutter technology delivers peak penetration rates in ductile formations as well as hard and abrasive formations without sacrificing durability.

Lancer™ shaped cutters cut with a more efficient point loading effect compared to Prism cutters. They are also more durable than Apex cutters, allowing them to be used in applications with more interbedded formations with carbonates, anhydrites, and high MW shales.

Well-engineered and well-tested

Each of these shaped cutters has been rigorously designed and tested using a structured development process to provide the most efficient cutter geometry for specific applications. And, before they are applied, our service delivery teams select the best drill bit frame for the application and establish the ideal placement of each cutter to maximize ROP and footage.

Contact your Baker Hughes representative for more information about how our PDC drill bits can help you drive performance while lowering your drilling costs.