Phoenix V|tome|x L450

限定されたサンプルサイズと密度で、高度なミニフォーカス CT スキャン

Phoenix V|tome|x L300システムの次の技術的な拡張段階として、Phoenix V|tome|x L450は、柔軟性、サンプルサイズ、450 kV / 1500 W Minifocusとオプションのよび300 kV Microfocus X線管による透過力をさらに向上させ、鋳造品、大型アセンブリ、AMパーツのボイド検出、欠陥検出、3D計測に最適なソリューションを提供します。

Phoenix V|tome|x L450 は、2D / 3D コンピューター断層撮影および 2D 非破壊 X 線検査用の、大型多用途ミニフォーカスシステムです。 グラナイトベースの操作により、大きなサンプルでも高精度で処理できます。 このシステムは、鋳造物やアディティブ部品のボイドや欠陥の検出および VDI/VDE 2630-1.3 に準拠した 3D 計測に最適なソリューションです。 オプションの high-flux|target を備えた、オプションの 2 次 300 kV マイクロフォーカス X 線管により、Phoenix V|tome|x L450 をあらゆる種類の工業および科学 CT 用途に適合させることができます。

ハイライト

Highlights

User Benefits

- Great flexibility for 2D and 3D inspection on a wide application range

- Fast CT acquisition and brilliant images by next generation highly sensitive Dynamic 41 detectors

- Leading exclusive Waygate Technologies core components such as X-ray tubes, detectors, software

- Excellent software modules for highest CT quality and ease of use

- High throughput cone scatter fan beam CT

- Dimensional measuring with extremely high precision, reproducibility, and user-friendliness

- Failure detection and reproducible 3D metrology of steel parts and large aluminium castings

- Leading measurement accuracy referring to VDI/VDE 2630-1.3 for reliable revalidation of system performance and reproducible metrology applications

Key Features

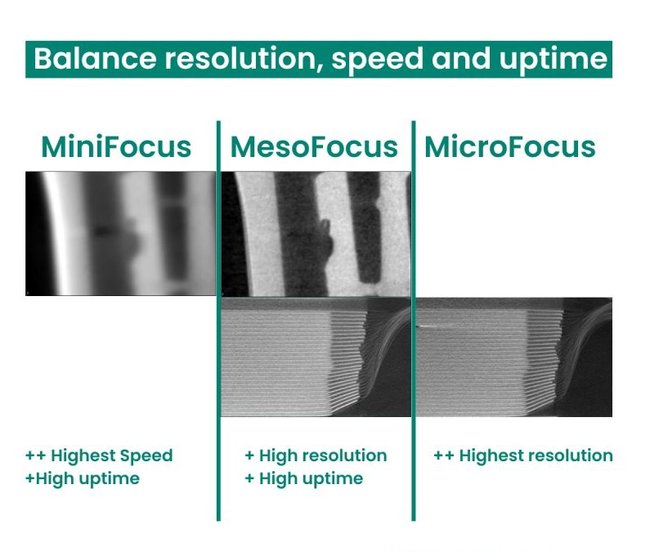

- Mini-/Meso-/Microfocus Dual|tube configuration

- Long-life|filament

- Scatter|correct technology

- Dynamic|41 technology detector

- Helix|CT

- Offset|CT

- Orbit|scan

- Multi|bhc

- Metrology|edition

- Ruby|plate

Applications

- High precision Mini-/Meso-/Microfocus CT

- Large Light alloys: Aluminum, Magnesium, Zinc (e.g. E-engine housings, gear boxes, large structure parts)

- Higher density alloys: Iron castings, titanium, nickel, cobalt

- Composite materials, large assemblies, AM parts

- Research: 3D printing, composites, battery cells and modules, ceramics, medical industry

- Reverse engineering: Metal, plastics, rapid prototyping, biomechanics

- Scientific research (plants, archaeology, animals, cultural, geo- and materials sciences)

Phoenix V|tome|x L 450 機能

- 450 kV / 1500 W bipolar Minifocus or the optional Mesofocus X-ray tube for higher resolution – specially optimized for CT applications

- Image

- Up to 10 times increased filament lifetime, ensuring long-term stability and optimizing system efficiency by Long-life|filament (optionally)

- Double CT resolution at the same speed, or double throughput at the same quality level as 200 µm pitch DXR detectors. Compared to 16-bit detectors, the optimized 14-bit technology offers the highest efficiency with a dynamic range of 10000:1 and thus saves time in use and also generates less noise in the image

- Scan even larger parts with up to ~70% larger scanning volume

- The Multi|bhc tool corrects streaking artifacts which typically occur as multiple dark streaking bands positioned between dense areas in multi-material samples

As part of the optional Metrology|edition, The Ruby|plate calibration phantom and the compensation of thermal drift effects based on the use of temperature sensors enable automated measurement sequences and precision to a new level of performance for even larger parts. The system guarantees a measurement accuracy of SD ≤ (6.8 ± L/100 mm) µm according to VDI/VDE 2630-1.3 for reliable three times faster revalidation of the system performance and reproducible measurement applications like:

- Nominal-actual CAD comparison

- Dimensional measurements / wall thickness analysis

- Reverse Engineering/Tool Compensation