Highlights

Benefits

- Reduce intervention risks and costs

- Maximize well production and reservoir recovery

- Cut carbon emissions by avoiding heavy workovers

Applications

- Subsea, dry tree, extended-reach drilling, and land ESP wells

- Late-life gas-lift wells with high water cuts

- Wells with heavyweight kill fluid that must be removed before flowing naturally

Retrieving a conventional electrical submersible pumping (ESP) system from a deep offshore well can cost you millions in workovers and expand your field’s carbon footprint.

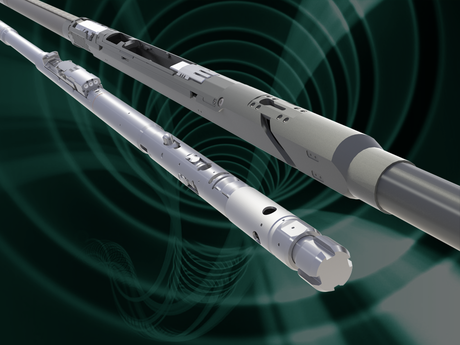

The AccessESP™ retrievable ESP system from Baker Hughes offers an efficient alternative that avoids the need for a heavy workover rig. The system comprises just three main components—a permanent completion assembly, an UpCable™ power cable, and a retrievable assembly containing the pump and an ultra-reliable permanent magnetic motor (PMM).

The retrievable assembly is easily removed and redeployed through tubing with industry-standard, light intervention equipment. While conventional tubing-deployed ESP and gas-lift completions require expensive, heavy interventions with a rig, the AccessESP system delivers tens of millions of added value over the life of a well—and with far lower emissions and fewer personnel on board.

The PMM incorporates unique design features to give you unmatched power density and reliability downhole. Conventional induction and PMMs must be stacked to achieve high horsepower (hp), making them longer, heavier, and less reliable in the process. But our PMMs achieve power density ratings up to 1,200 hp in an ultra-long life, single-section design. You get optimal power output to boost your well’s production, with significantly lower logistics and inventory costs.

With several years of failure-free performance, the AccessESP system is field-proven to reduce risk, lower total cost of operations, and cut carbon emissions in high-value wells, both offshore and on.

Contact us today to learn how the AccessESP retrievable ESP system can help you capture the full value of your producing wells, in less time and with lower risk.