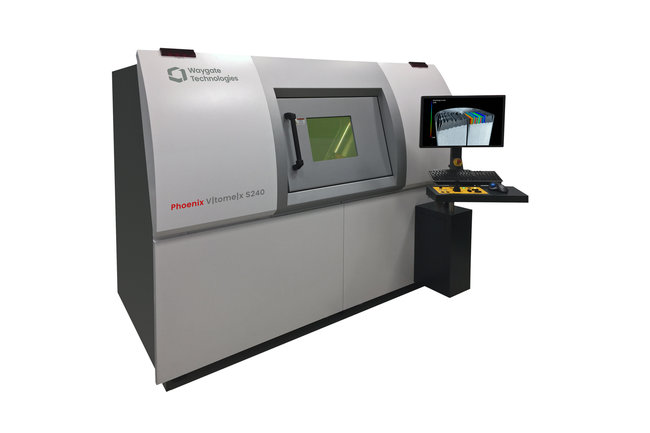

Phoenix V|tome|x S 240

Advances in inspection technology have yielded a highly versatile high-resolution system for 2D X-ray inspection and 3D computed tomography (microCT and nanoCT®) and 3D metrology. CT scanning of smaller assets is now more efficient than ever thanks to up to two times faster microCT scans and doubled resolution.

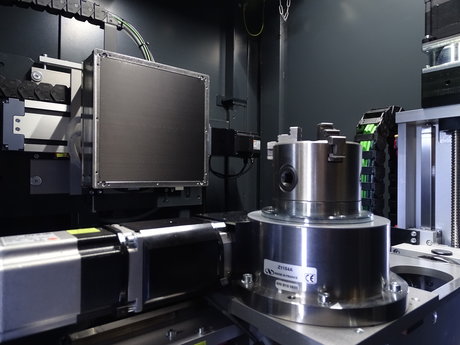

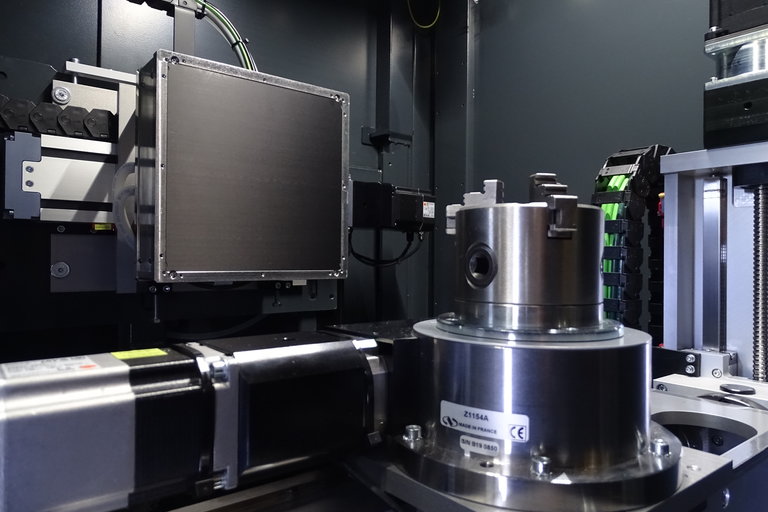

The Phoenix V|tome|x S 240 is one of the few CT systems worldwide combining the highly efficient Dynamic 41 detector technology and High-flux|target — enabling high image quality as it scans much faster, or with improved accuracy, and truly revolutionizing inspection.

Whether you need to increase speed, detection detail, or do both, the Phoenix V|tome|x S240 Waygate Technologies, a Baker Hughes business, can be formatted for any 3D industrial or scientific microCT task. This CT scanner is ideally suited to meet inspection challenges in the electronics, R&D, scientific, and automotive industries.

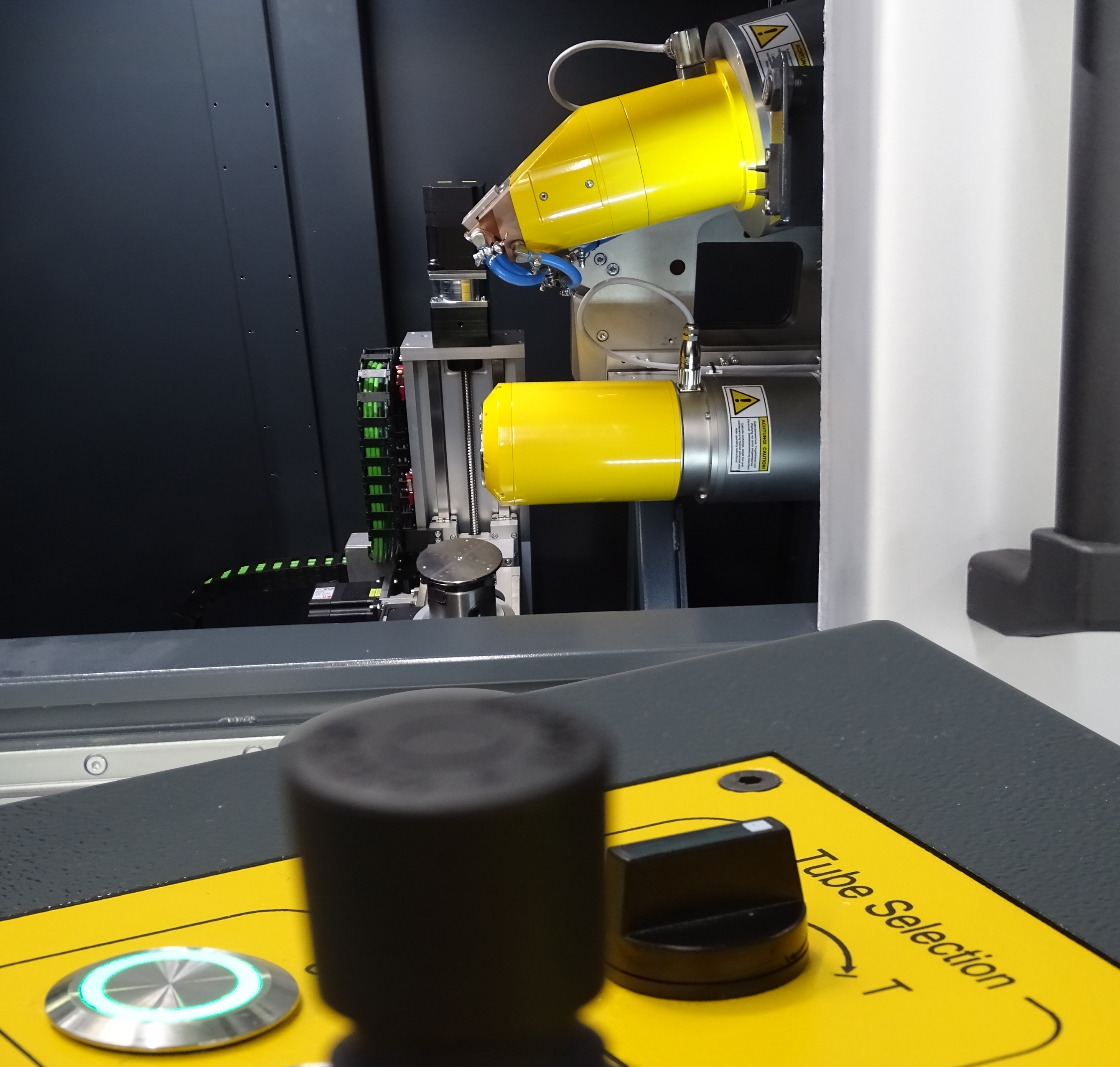

To allow high flexibility, the V|tome|x S240 may optionally be equipped with both, a 180 kV/20 W high-power nanofocus X-ray tube and a 240 kV/320 W microfocus X-ray tube. Due to this unique combination, the system is an ideal tool for a wide range of applications from extreme high resolution nanoCT scans of low absorbing materials with best detail detactabilty of 0.2 micrometer as well as for 3D analysis of higher absorbing objects of up to 15 kg weight and 500 mm in diameter with microCT.

Highlights

Benefits

- Multiple configurations possible. Flexible open nanofocus-microfocus dual tube combination possible (e.g. 180 kV/20 W high-power nanofocus X-ray tube)

- 3 different detector options depending on the inspection task, e.g. DXR S100 Pro with 2,500x3,000 pixels at 100 μm pixel size for superior resolution

- Ultra-reliable. Up to 10 times increased filament lifetime, ensuring long-term stability and optimizing system efficiency by long-life|filament

- Increased speed without compromising image quality. Up to 2 times faster data acquisition at the same high image quality level by Diamond|window

- Maximized scan flexibility with optional Offset|scan und Helix|scan capability

- High throughput at high result quality thanks to the highly efficient Dynamic 41 detector technology and High-flux|target

Features

- Dual|tube: 240 kV / 320 W microfocus X-ray tube - specially optimized for CT applications optionally combined with a high power microfocus X-ray tube

- Helix|CT: Scan longer parts with improved image quality to increase probability of detection (POD) with efficiency and ease

- Offset|CT: Scan even larger parts with up to ~70% larger scanning volume

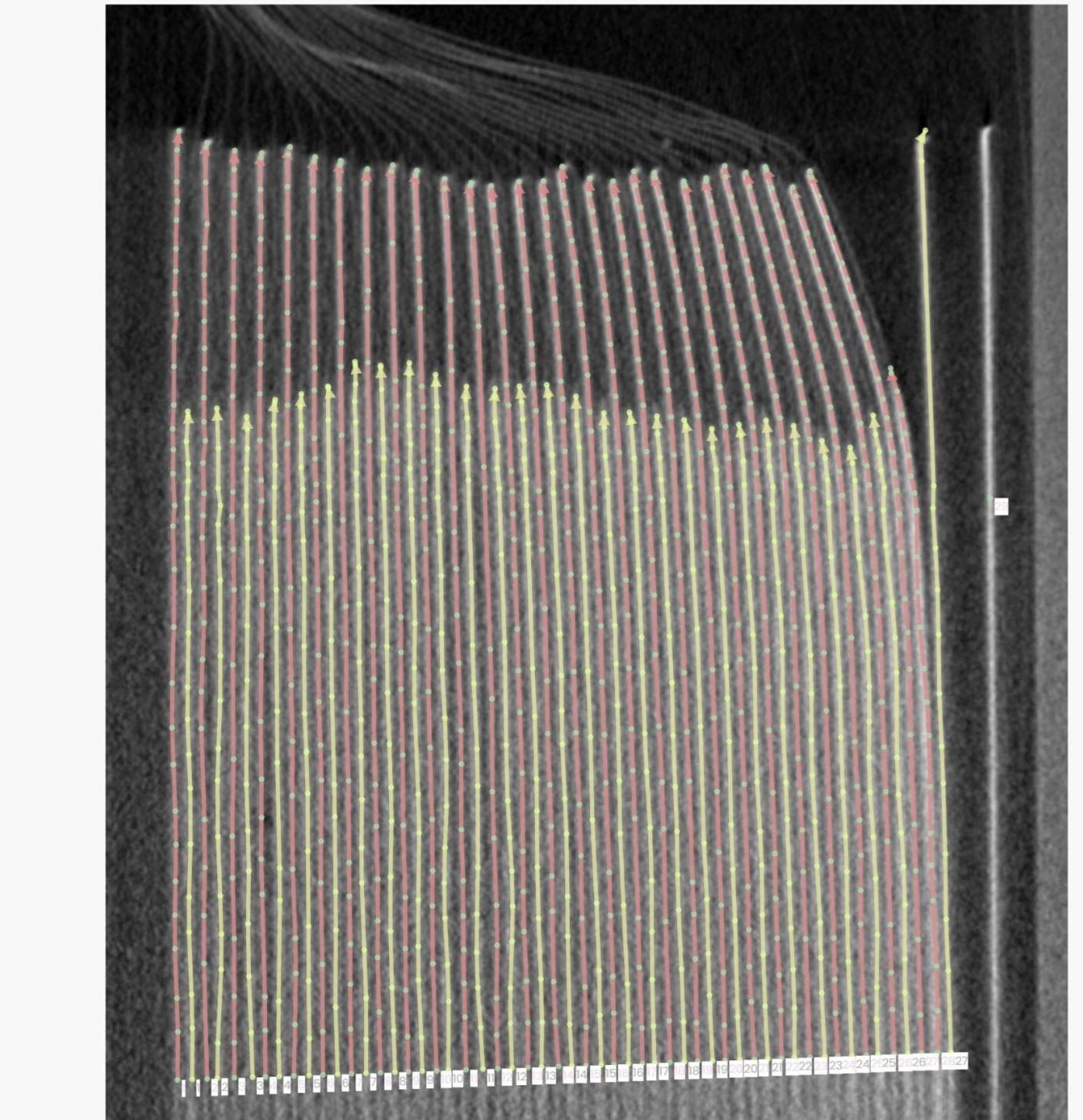

- Orbit|scan: Define a virtual scan rotation axis for ease of scan adjustment and flexible ROI CT scans

- Long-life|filament: Up to 10 times increased filament lifetime, ensuring long-term stability and optimizing system efficiency by Long-life|filament

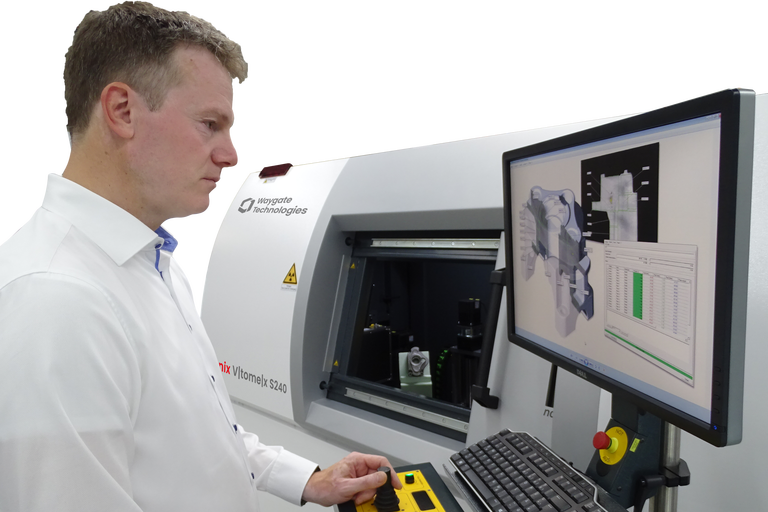

- Phoenix Datos|x CT software: Fully automate your data acquisition, volume processing, and evaluation with ease

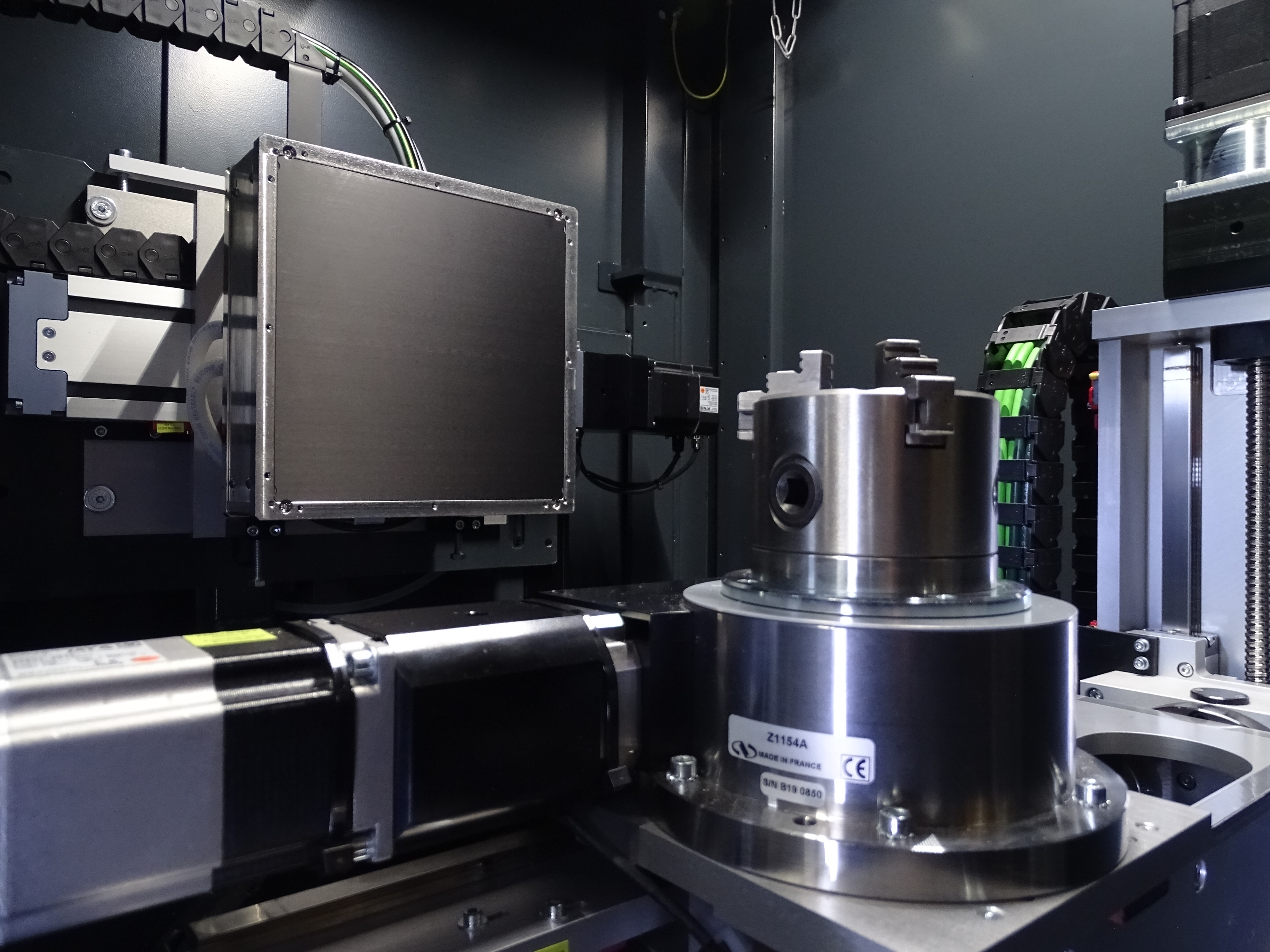

- Full 2D inspection capability: Manipulator tilt axis (+/-45°) for fully flexible radiographic inspection

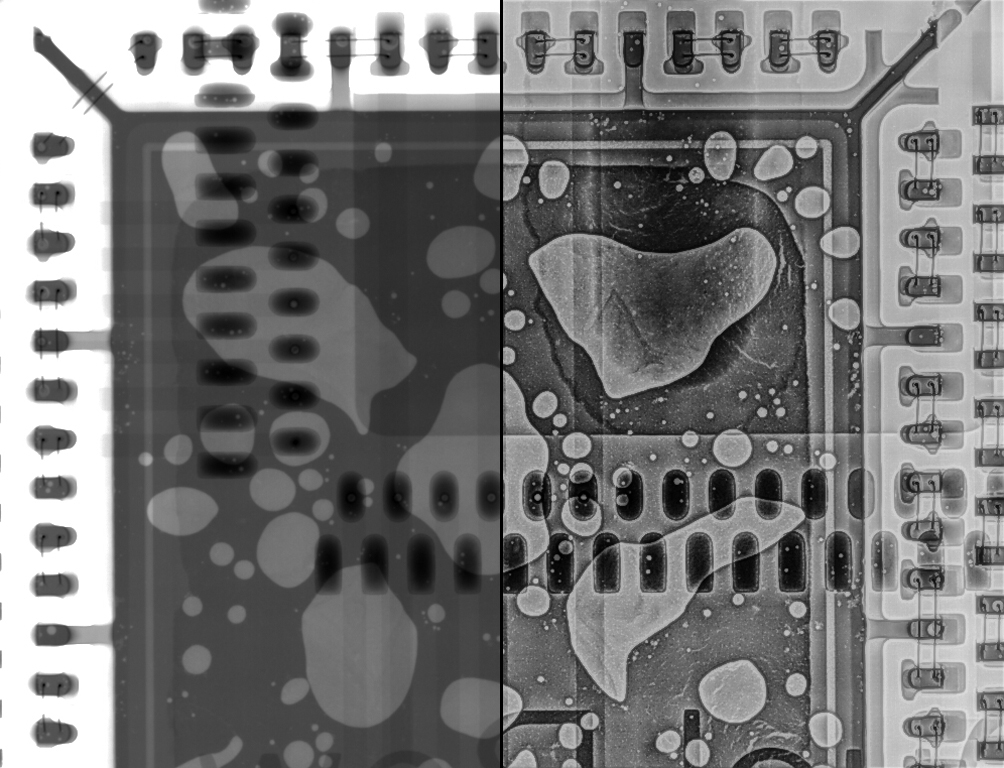

- Flash! image optimization: Next generation of superior defect detection, optimized for 2D electronics and casting inspection

Applications

- Internal defect analysis

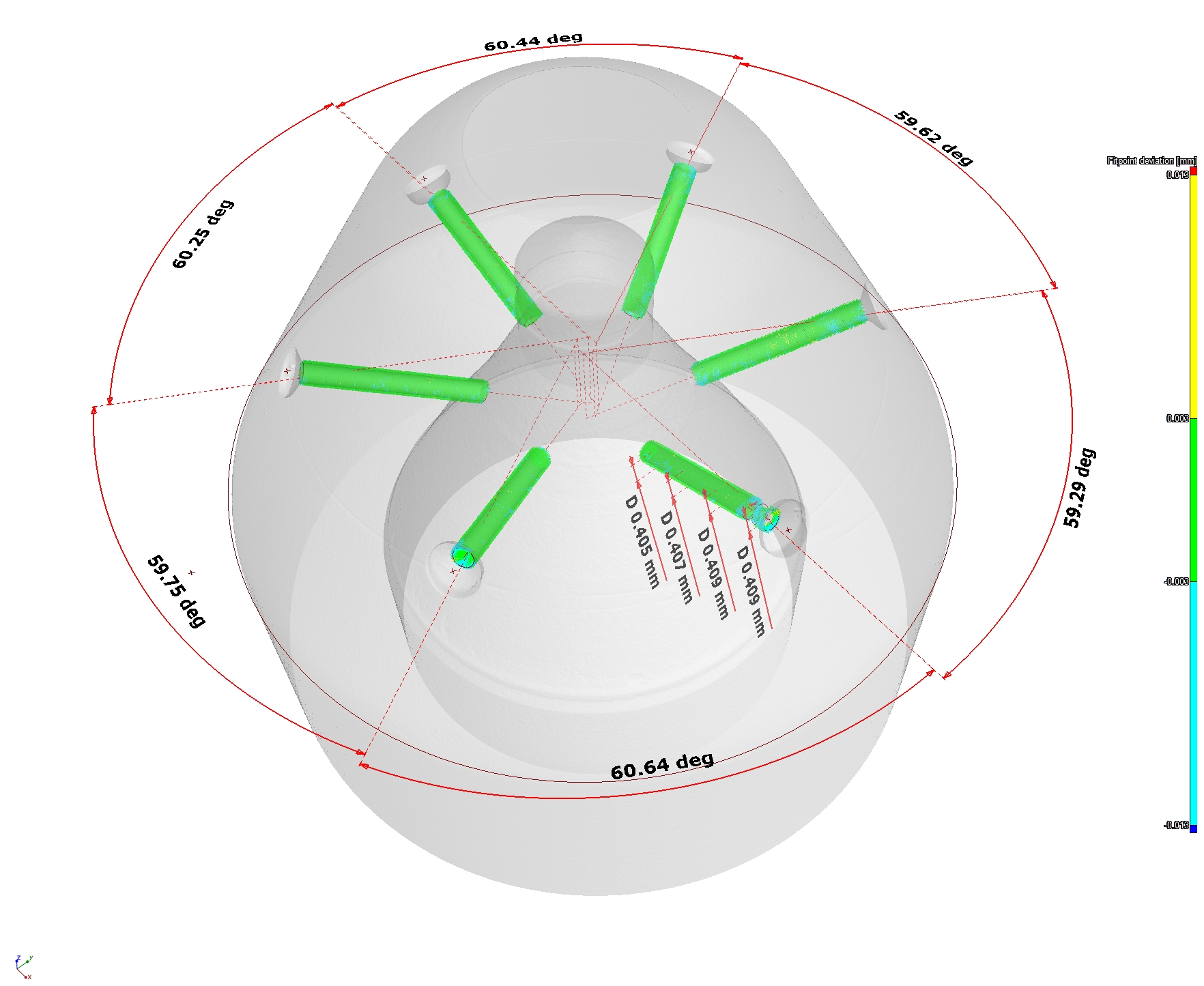

- 3D quantitative porosity analysis

- Flexible 2D X-ray inspection

- nanoCT enabled materials structure analysis

- Assembly control

- CAD Data nom/act comparison

With approximately 500 units sold, the Phoenix V|tome|x S is the dual-tube CT system with the widest installation base worldwide, offering an unique flexibility from 2D radiographic inspection to micro- and nanoCT. With the recent launch of the next V|tome|x S generation, the system is better than ever before.

Choose the best detector option depending on your individual inspection needs:

- Temperature stabilized Dynamic 41|200p+ large area detector with superior image and result quality, 410 x 410 mm (16” x 16”), 200 μm pixel size, 2036 x 2036 pixels (4 MP)

- DXR S100 Pro detector, 100 μm pixel size, 2,500 x 3,000 pixels for superior resolution and outstanding detectability on a 300 mm x 250 mm large active area - optional with 1.3x virtual detector enlargement

- Temperature stabilized DXR 250RT detector array with 20 fps for real-time inspection, 200 μm pixel size, 1,000 x 1,000 pixels on a 200 mm x 200 mm large active area with 2x virtual detector enlargement

The patented High-flux|target makes CT scanning more efficient due to up to two times faster CT scans or doubled resolution. Review results faster than ever thanks to Accelerated 3D CT reconstruction by Velo|CT and automated generation of first article inspection reports available in one hour or even less.

With its 5-axes manipulation for 2D and 3D inspection of samples up to 10 kg and up to 500 mm in diameter, the Phoenix V|tome|x S is a compact allround system, especially in its optional Dual|tube configuration, combining the submicron detail detactability of the 180 kV nanofocus X-ray tube with the inspection power of the 240 kV microfocus tube. Fast and easy tube exchange just by a push of a button.

The 3D Measurement package powers reliable precision results while simplified software and fully automated execution of CT scan, reconstruction and analysis process makes capturing and reproducing high-quality inspection images easier than ever.

Proprietary machine learning (ML) based algorithms deliver exceptional Automated Defect Recognition (ADR) across various flaws for e.g. battery anode overhang analysis or typical casting defects. Our AI and data science based ADR library yields greater accuracy and enhanced ease of use compared to conventional ADR approaches, eliminating the need for expert parameterization skills.

Waygate Technologies offers X|approver, the next level and premium ADR platform consisting of the full and intuitive workflow management as well as a comprehensive ADR library running in the background of your production delivering automatic decision making. On top of it reporting functions are provided to see potential negative trends in production at a glance. Any authorized operator can parametrize scanned samples (e.g. for highly accurate overhang issue detection), and the algorithms get more accurate over time.

For advanced 2D inspection, the Phoenix V|tome|x S includes X|act inspection software with industry leading Flash!™intelligent image processing technology for optimized failure detection. Users benefit from two versions:

- Flash! (for general NDT use such as casting inspection)

- Flash! Electronics (optimized for Electronics inspection)

Technical Specifications

No additional options are needed. The V|tome|x S already includes the manipulator tilt axis (+/-45°) and the quality|assurance NDT software for autopositioning (CNC) and digital image processing in the standard version.

V|tome|x S can be ordered in a Dual|tube configuration. This setup expands the application range significantly and allows the user a fast and easy switch between 240 kV/ 320 W microfocus X-ray tube and 180 kV / 20 W nanofocus tube, just by a push of a button.

Down to 2 µm for the 240 kV / 320 W microfocus tube and down to < 1 µm for the 180 kV nanofocus tube

10 kg for full 2D radiography and 3D CT. Higher load up to 30 kg depending on sample shape and application on demand.