Waygate Technologies is working with the energy industry to optimize the future of power. Our power generation solutions benefit coal-fired, nuclear, natural gas, hydroelectric, wind turbine, and other power generation plants. From software that helps customers identify problems before they arise, to hardware backed by decades of ingenuity, our solutions power the energy industry to maximize asset integrity and mitigate costly shutdowns.

We maximize asset integrity and mitigate costly shutdowns

Global growth in population and investment in developing countries will drive energy demand and a need to supply it.

Availability is crucial and managing maintenance and unplanned downtime is key.

Short term changes to gas to meet overall demand will require additional resources.

Inspection of equipment in high risk areas, pressure containing equipment, and confined spaces

Increase loads and fatigue which lead to unplanned failures, difficult to access components, and limit to efficient-working time on turbines.

Cranes: $75k, jack-up: $250k/day, main bearings: $95k -$400k, and adding on top the production loss

Remote connectivity, data access, data analytics, and cloud services

Paramount to correlate variables (vibration, temperature, power, speed, pressure, oil condition, ...)

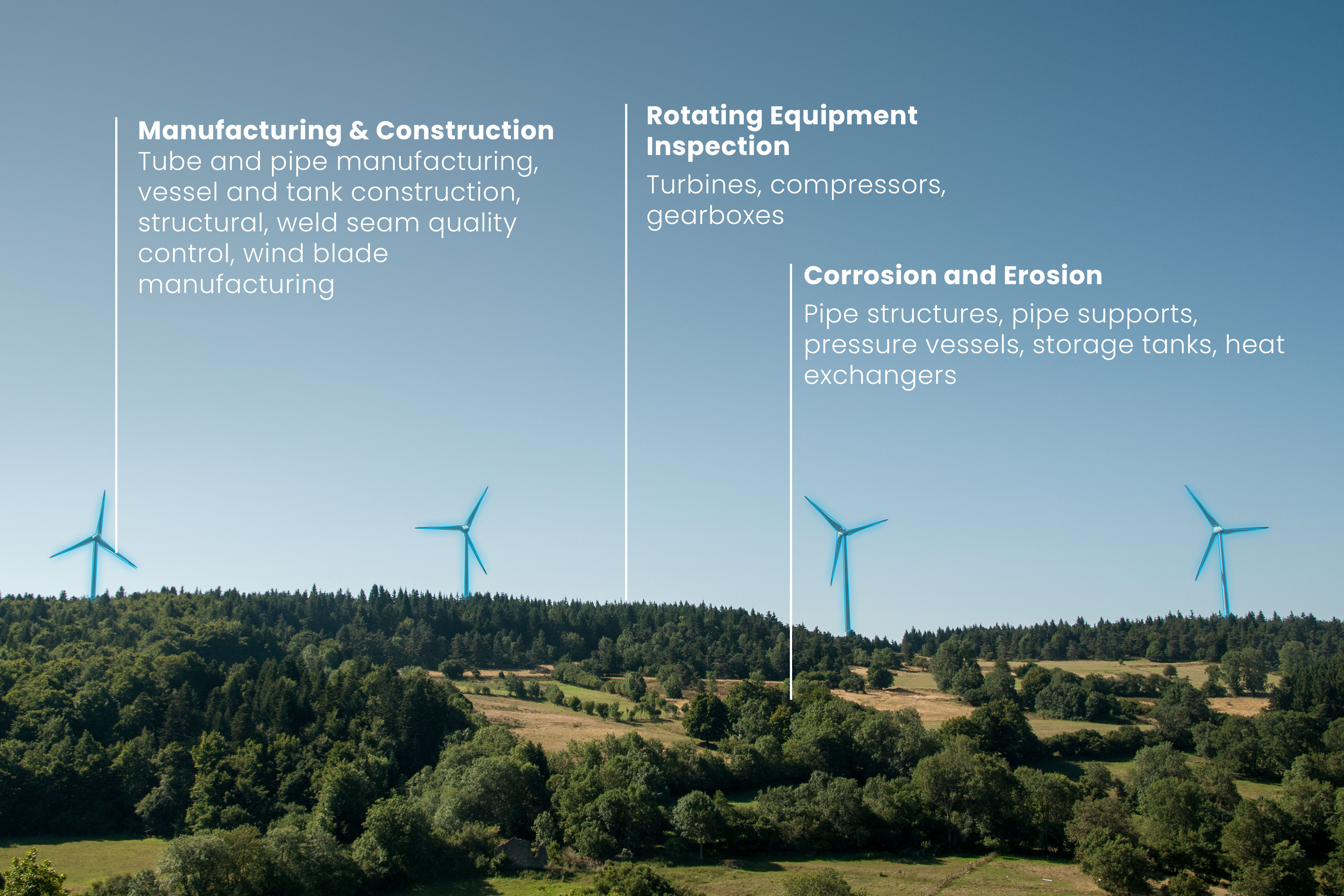

From composites to confined spaces & inaccessible areas inspection, to corrosion & erosion monitoring, rotating equipment and weld inspection

Technologies made for your industry challenges

The use of composite materials has surged across industries over the past several years, now commonly used in a variety of safety-critical parts. We can help you inspect even large parts made from composites at speeds that keep up with ever-changing needs of the energy industry. From wind to gas turbine blades, our solutions are designed to meet even the most demanding energy inspection requirements with very high throughput rates.

Throughout the state-of-the-art factories and plants across all industries, are complex, dangerous, and even impossible areas to inspect, that are crucial to their productivity. Specialized RVI devices offer a non-intrusive alternative that not only alleviate inspection limitations on areas like piping, tanks, and turbines, but offer higher quality analysis, in real time.

Identify corrosion and erosion risks before they impact your operation with a full range of advanced solutions from Waygate Technologies, from thickness gauges to tank annular plate scanning and Predictive Corrosion Management.

When time is your most valuable asset, we want to help you make the most of it. Our InspectionWorks Software Platform helps you transform inspections from a necessary cost to a critical flow of data enabling better product design and optimization.

Detecting flaws both during fabrication and in service is critical to safety. Waygate Technologies has been trusted by the energy industry for decades to deliver outstanding performance by combining a tremendous depth of application expertise with the fastest and most capable ultrasonic instrumentation available today.

Ensure the quality of critical parts like turbine blades and be confident you have the most accurate inspection data. Waygate Technologies provides the energy industry with comprehensive inspection solutions for rotating equipment including computed tomography, remote visual inspection, eddy current testing and more.

Our vast portfolio includes condition monitoring solutions for predictive maintenance and asset lifecycle optimization, sensors, software, and service, lube oil monitoring, and cybersecurity solutions

Wind turbines allow us to harness the power of the wind and turn it into energy. We deliver the right solutions for inspection to increase uptime and avoid downtime.

Waygate Technologies has the solutions the energy industry needs to inspect welds for quality. Our partners use a range of our technologies including field radiography, conventional and phased array ultrasonics and remote visual inspection to ensure weld integrity and compliance.

Get in touch with one of our Waygate Technologies subject matter experts.