Waygate Technologies Launches Mentor Visual iQ+ Video Borescope

Waygate Technologies, a Baker Hughes business, Launches Mentor Visual iQ+ Video Borescope

- The latest evolution in the Mentor product line features an upgraded central processing unit (CPU) that boosts inspection productivity

- New Blade Counter 2.0 feature automates inspections, utilizing machine learning and an integrated turning tool for streamlined gas turbine inspections across multiple sectors

- Voice control and improvements in steering and articulation enhance user experience

HUERTH, Germany, February 7, 2024 – Waygate Technologies, a Baker Hughes business and market leader in non-destructive testing (NDT) solutions for industrial inspection, has introduced Everest Mentor Visual iQ+, the latest version of the highly successful Everest Mentor Visual iQ VideoProbe™. Utilizing advanced analytics for novel inspection approaches, the new state-of-the-art flagship video borescope technology harnesses the power of Artificial Intelligence (AI) and machine learning to enhance data quality and reduce inspection time for critical inspections across multiple sectors, including aviation and power generation.

Improved performance with longer battery life

Everest Mentor Visual iQ+ (MViQ+) is equipped with an upgraded central processing unit (CPU) that allows for simultaneous execution of advanced analytics, tools and features, coupled with a 10% extension in battery life.

Its functionalities encompass:

- high-definition visual inspections

- simultaneous recording of HD video and

- images

- generating 3D asset representations with precise measurements

- stitching multiple 3D views

- blade counting

- object and defect recognition

- streaming video with control on iOS or Android devices

- Wi-Fi and Bluetooth connectivity for local and cloud data transfer as well as hands-free use

The MVIQ+ also introduces updates to the steering and articulation engine supporting consistent performance over time. The high-power steering motors not only extend the articulation range and performance, but also ensure consistent response and feel tied to user input. The solution offers a diverse selection of interchangeable probe diameter and length options, providing flexibility to meet a variety of inspection needs.

Optimized efficiency in gas turbine inspections

With no setup requirements, MViQ+ utilizes machine learning to automatically identify blades and other components within a gas turbine. Moreover, a two-way turning tool integration allows motor control directly from MViQ+, streamlining the entire inspection process. The integrated tool offers on-screen options, facilitating rotation control directly from the borescope handset. This adds substantial value to gas turbine inspections, catering to both aviation and power generation applications.

“Hey Mentor” and voice activated commands

Enhanced ease-of-use and performance are seamlessly integrated through voice control, enabling inspectors to execute common tasks hands-free while maneuvering and steering the probe. Using a purpose designed, built-in, far-field microphone array and specialized audio system, adjusting brightness, initiating measurements, and more commands are available with a straightforward verbal prompt starting with “Hey Mentor,” unlocking a multitude of possibilities. Additionally, the Learn More content is directly embedded into the MViQ+ operating system, offering users convenient access to training materials for further guidance and assistance.

High measurement- and image quality

MViQ+ retains all the proven features of its predecessor. Leveraging TrueSight™ Imaging, users can capture high-resolution live video and still images with a 1.2-megapixel sensor enabling robust digital zoom. Enhanced by high image resolution, precision optics, and features such as HDR, DarkBoost and adaptive noise reduction significantly improves the likelihood of detection.

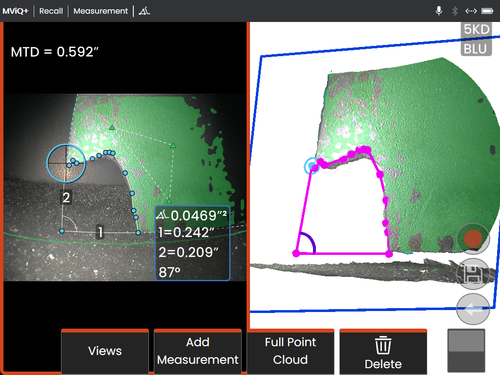

Moreover, Real3D™ Measurement provides on-demand measurements with real-time cursor adjustment within the full-field point cloud. It facilitates the creation and measurement of larger areas through 3D stitching, offering up to twelve measurement types, including automated measurements to assist the inspector, for accurate and efficient results, including new capabilities such as Missing Corner for providing the area of a missing blade and Surface Angle for measuring deflection of tip curl during blade inspections.

Easy setup and automated processes

This innovation extends to the entirely revamped design of MViQ+. The lightweight and durable construction is achieved through a military-grade magnesium housing, featuring a modern touchscreen interface that complies with IP65, MIL-STD-810H, and MIL-STD-461G standards. Hardware enhancements also include a pole mount kit, an expanded storage capacity from 32GB to 160GB, and new hardware ports that facilitate HDMI connectivity and warm swap battery replacement.

###

Learn more and about the industrial inspection portfolio from Baker Hughes Waygate Technologies:

- Everest Mentor Visual iQ+ Product Page and Video

- Waygate Technologies Remote Visual Inspection Solutions

- Waygate Technologies LinkedIn Channel

- Waygate Technologies YouTube Channel