Highlights

Highlights

Benefits

- Up to two years faster from inception to operation—including significantly fewer on-site personnel and less site time

- Lower engineering and construction costs with fully tested plug-and-play modules delivered to site

- 20-30% less CO₂ lowering the carbon footprint of the liquefaction process

Features

- Compact liquefaction modules (0.8 up to 1.5 MTPA) can be added incrementally to increase capacity while managing financial exposure

- Power-generation building blocks add to flexibility and maximize operability between power and liquefaction

Applications

- Onshore and offshore LNG

- Small to medium scale resources

- Ideal for remote locations

Featured Video

Overview

Overview

Many LNG reserves around the world (both accessible and remote) are too small to be economically viable with the traditional large-scale, stick-built approach to engineering and construction.

Our solution changes that with pre-constructed turnkey LNG modules that minimize risk and give you total control over business growth strategies.

Even the 1-MTPA range is now viable and easy. Our modules can be quickly commissioned and scaled up by one or more at a time— to meet any gas demand.

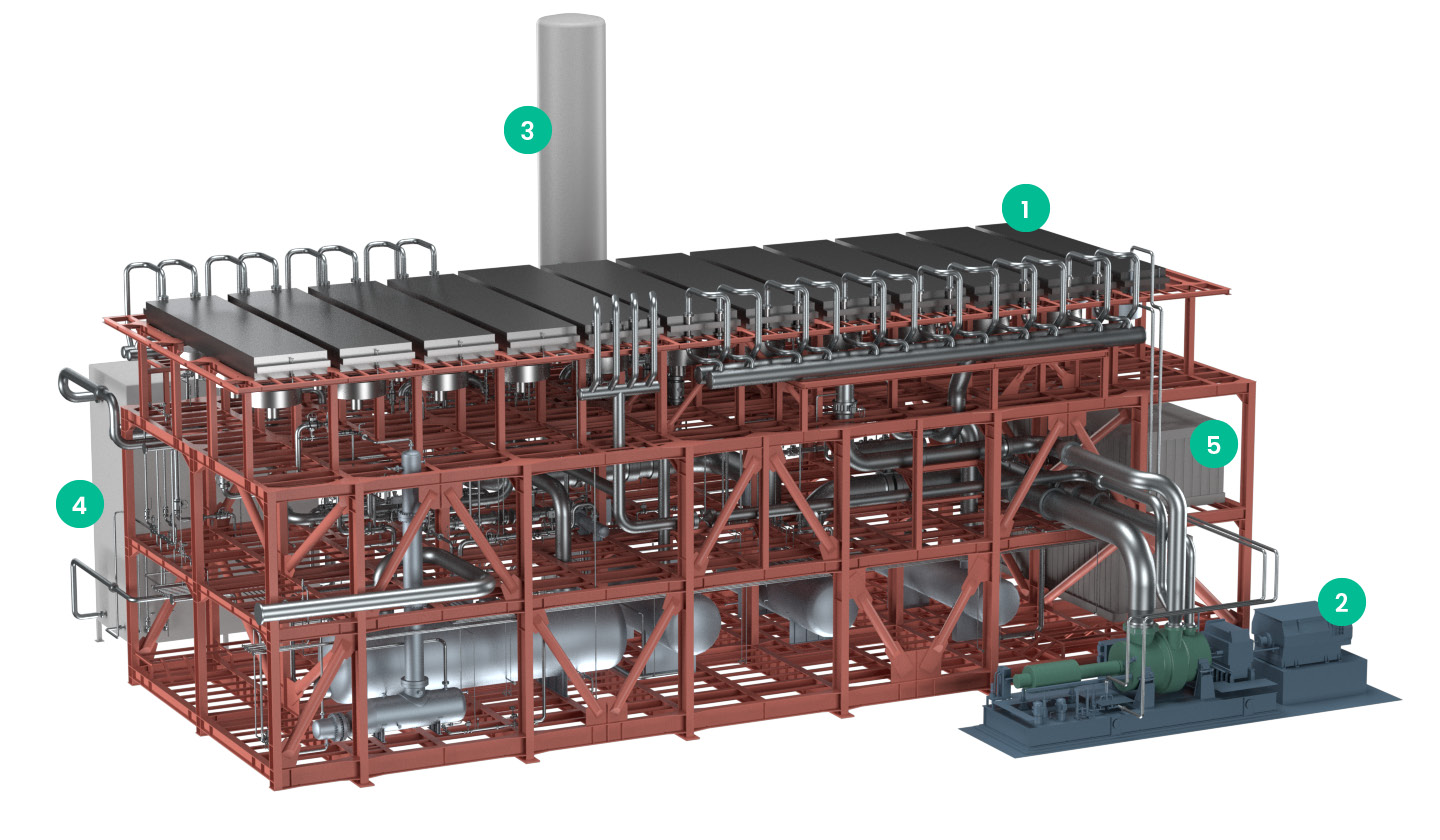

Liquefaction module

With a production capacity of 1-MTPA range of LNG, each module weighs 3,500-4,500 tons and has a total plant footprint of just 2,500-3,500 m2. Driven by an electric moto-compressor, the liquefaction process produces zero emissions.

1. Process module

- Air coolers

- Vessels

- Electrical control cabins

- Separators

- Scrubbers

2. Electric moto-compressor

- 40-50 MW class with common soft start

- Other drivers available on request

3. Surge vessel

- Refrigeration storage

4. Cold box

Brazed Aluminum Heat Exchangers (BAHX)

5. e-room

- Soft starter

Power-generation building blocks

Each block can power up to three liquefaction modules—with the proven performance of up to four LM9000 gas turbines (including spare) and one SC2-19 steam turbine.

LNG capacity (MTPA)

PG blocks

Running gas turbines

Spare gas turbines

Steam turbines

2-3

1

3

1

1

6-8

2

7

1

2

10-12

3

11

1

3

They ensure 99% availability and provide heat extraction to process. The LM9000 can meet CCGT requirements and power-generation integration with renewables.

We are currently developing a battery pack that will eliminate the need for the gas turbines spinning reserve.

Low-risk construction and installation

The liquefaction modules and power-generation blocks are all fully constructed, tested, and commissioned at our yard in Avenza, Italy, before shipping to your project site. Upon arrival, final installation is 30% faster than traditional stick-built approaches, and requires 60% fewer on-site personnel (figures are indicative; results vary depending on project specifics). These factors, along with simplified interconnections and civil works, dramatically reduce project costs.

The pre-tested, modular approach minimizes site non-conformities, enables exact replication from one module to the next, and ensures a predictable schedule with minimized risk.

Our Avenza yard has comprehensive capabilities, including:

- ~290,000 m2 and expanding

- 2 covered warehouses, 27,000 m2 combined

- 1.5 km from Carrara Port

- 4,000 tons load-out capacity

- 20 erection and testing areas

- Testing for power-generation modules at full speed and full load up to 130 MW

- Testing facilities under development for large LNG mechanical-drive trains at full speed and full load

- Avenza-Massa-Florence proximity enables seamless interaction between all our engineering, construction, and testing resources