Highlights

Highlights

Benefits

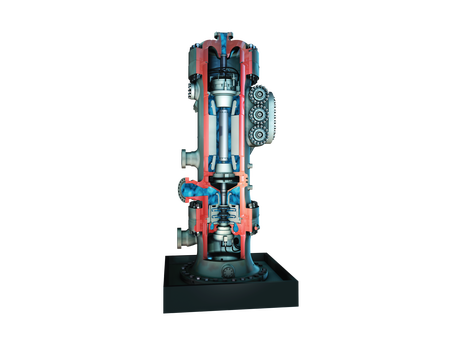

- Extremely robust and compact design with single-sealed housing to withstand extreme pressures and temperatures

- Compact and standard package eliminates high-cost platforms and enables easy and fast installation

- Vertical orientation protects electric motor from raw process gas, drains liquids. and reduces the module's overall footprint

Features

- Available with power up to 15 MW, with the same pressure and flow ranges as conventional natural gas compression applications

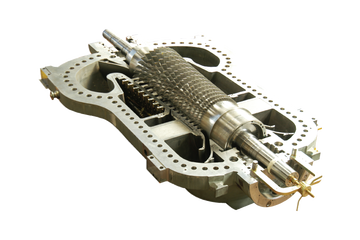

- Active magnetic bearings eliminate oil system and dry gas seal for higher uptime

- Diffuser separation system and dust removal device for wet gas compression

Applications

- Subsea gas boosting

Overview

The Blue-C™ subsea compression module is a viable solution to extract resources that were previously not economically recoverable. Driven by a gas-filled, high-speed electric motor, and stacked in a vertical orientation, the single-sealed package enables easy installation, and ensures reliable production for up to five years.

The high-tech solution for low-margin wells

The Blue-C™ subsea compression module includes a number of creative engineering solutions that have resolved the significant technical challenges associated with highly reliable yet unattended operation. For example, Blue-C™ successfully eliminates dry gas seals using a gas-filled motor, special materials, and design procedures specifically developed for this application.

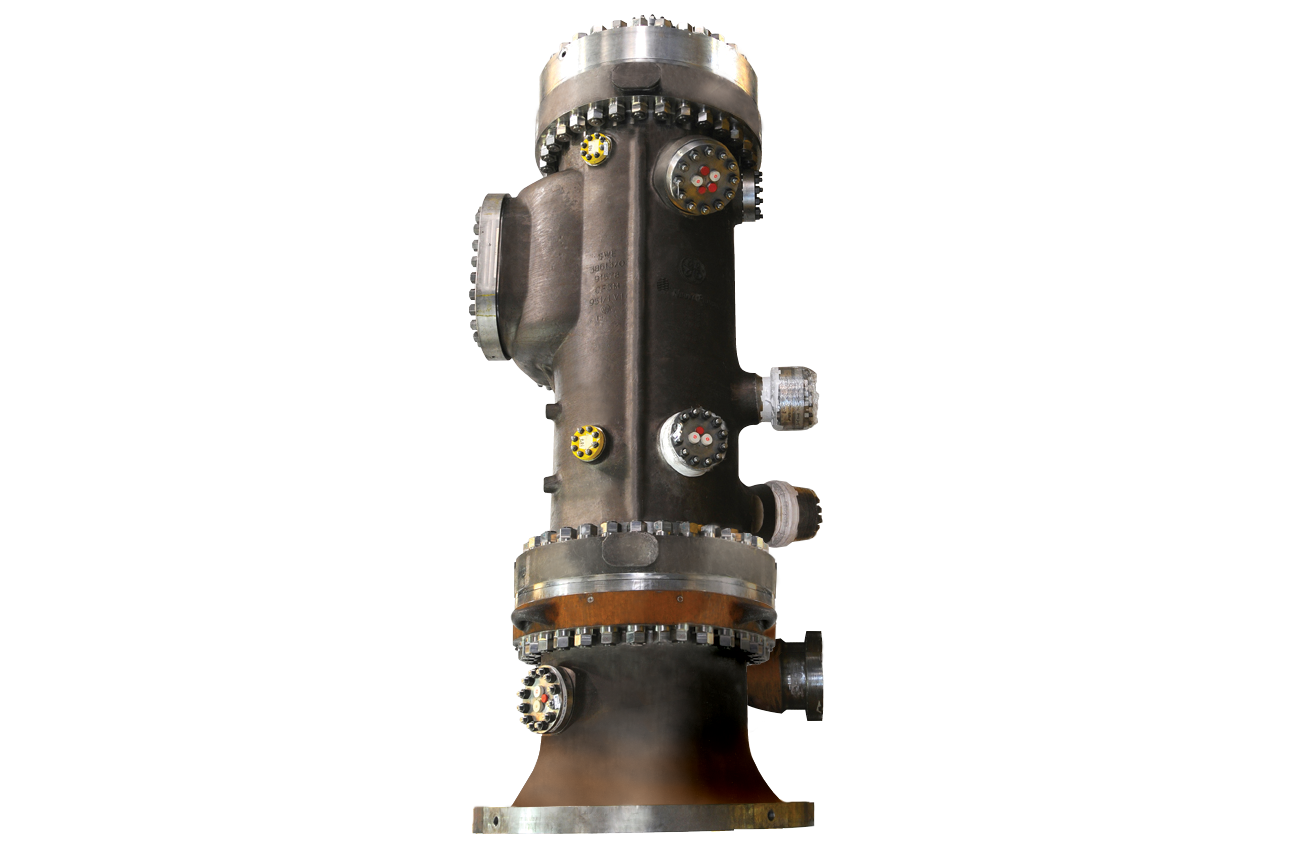

Product qualification

In 2010 at our Le Creusot facility, the first prototype successfully underwent complete factory acceptance test (FAT), mechanical running test, full-load test, and vertical landing test at full scale. In 2011, Blue-C™ was fully validated in a real gas reservoir in Nyhanma, offshore Norway, with a two-year submerged test including seawater cooler, marinized control system, variable-speed drivers, and complete endurance testing. The machine was subjected to more than 294 start-ups, ran at maximum power for more than 72 hours, and was extensively tested in both design and upset conditions for more than 280 days. Results illustrate that Blue-C™ provides excellent reliability under pressure.