Highlights

Highlights

Benefits

- Get superior hole quality, longer laterals, and faster ROP with continuous proportional steering

- Ensure precise well placement with near-bit directional and azimuthal gamma-ray measurements

- Navigate drilling dysfunctions with high-resolution vibrati

Applications

- Wells requiring high build-up rates

- Simple or complex 3D wellbores

- Single-run verticals, curves, and laterals

Overview

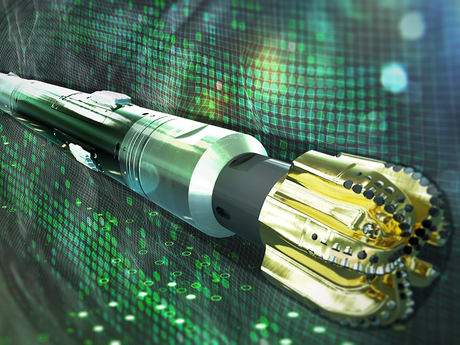

To keep your directional drilling costs down while ensuring optimal production, you need a smooth wellbore that is placed in your most productive zone. The Baker Hughes AutoTrak™ Curve Pro high build-up rate rotary steerable system (RSS) provides a solution, delivering smooth, precise, and fast drilling in your high build-up rate directional drilling applications.

Precise control in any formation

Achieve accurate wellbore trajectory control in any formation trend with the AutoTrak Curve Pro RSS’s advanced wellpath trajectory control system. The system combines azimuthal hold, inclination hold, new electronics, and firmware to automatically correct the well’s trajectory to reduce tortuosity, torque, and drag. Your drilling operation builds out better curve sections and longer lateral sections, with fewer downlinks for more on-bottom time and increased overall rate of penetration (ROP).

Maximize your well’s contact with the reservoir with the RSS’s near-bit directional and azimuthal gamma-ray measurements. These measurements give you a quick response time that minimizes the need for high doglegs to navigate back to the highly productive “sweet spot” in the reservoir. You get a high-quality wellbore that ensures more trouble-free casing and completion deployment.

Directional control and well quality are further assured with the AutoTrak Curve Pro RSS’s continuous proportional steering functionality. The system uses three precision-controlled pads to maintain a continuous proportional steering vector to drill a smooth, in-gauge hole. The system measures azimuth and inclination every millisecond and automatically adjusts steer forces for precise control, even at high ROPs.

Drilling dynamics have no impact on steering control, as the precision-controlled pads are powered by internal hydraulic power on a decoupled, slow-rotating sleeve. As a result, the pads operate independently of bit pressure, flow rates, and drilling fluid properties, giving you the ability to optimize your bit and hydraulics program as new formation challenges arise. And by combining the proportional steering with the wellpath trajectory control system, you get wide-ranging versatility and reliability in formation types from soft to hard, allowing you to drill the vertical, curve, and lateral sections in a single run.

Implement with ease

The AutoTrak Curve Pro RSS is easy to implement on your bottomhole assembly (BHA). The one-piece system is ready to pick up when it arrives at the wellsite and has only two connections to manage—one with the drill bit and the other with the rest of the BHA.

The AutoTrak Curve Pro RSS is also fully enabled for Baker Hughes Remote Operations Services. Our drilling and evaluation experts use their experience from thousands of wells, along with proprietary systems and advanced technology, to remotely execute your drilling operation with superior efficiency and consistent results.

Contact us to learn how the AutoTrak Curve Pro RSS can deliver superior directional drilling performance for your wells.