Highlights

Whatever your drilling challenge, we use our Bit Selector tool to identify the right bit for your application.

- Formation challenges

- Operating envelope

- Bottom-hole assembly

Choosing the right bit for each well helps achieve the rate of penetration, bit life, and build-up rate you need.

- Digital twin modeling

- AI-powered search engine

- Fully equipped test rig

We work collaboratively with you to define your field-specific challenges and quickly identify the right bit for every job.

- Rapid searches

- Extensive domain expertise

- Drill bits for all applications

Poor drill-bit selection results in disappointing rate of penetration, sub-par build-rate, and too many trips. To reduce non-productive time and manage costs, it’s vital to match your bit to three factors: the formation, your operating envelope, and the bottom-hole assembly.

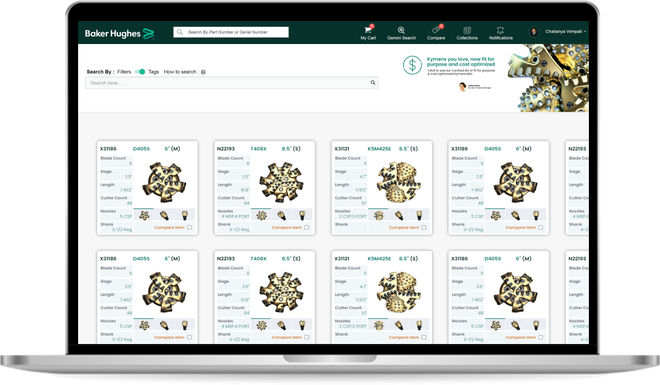

Our Bit Selector tool rapidly assesses all three to identify the perfect bit from our comprehensive product range—whatever your field-specific drilling challenge.

Leveraging advanced data-driven modeling and powerful computer simulations, our decision-making process is rooted in extensive domain expertise. With decades of experience in bit design and manufacture, we know drill bits and how they perform in any given situation.

Our artificial intelligence-powered, web-based application can build a digital-twin model that identifies the perfect bit to meet specific drilling challenges.

This isn’t just theory. It’s based on a powerful combination of advanced rock modeling and validation in our fully equipped test rig. The end result? Fewer trips, less downtime, and superior efficiency.