Horizontal pumps from Baker Hughes give you proven surface pumping solutions that extend your artificial lift run time and save you money.

Improve surface pumping with less cost and risk

Our HPump™ surface pumping systems deliver longer run life and lower maintenance costs than positive displacement and progressive cavity pumps. And with some of the shortest lead times in the industry, our horizontal pumps help you react quicker and save time when scaling up or down as needs change.

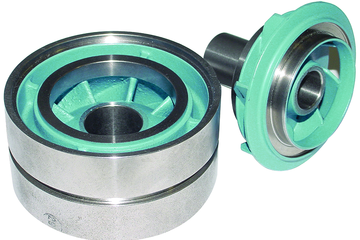

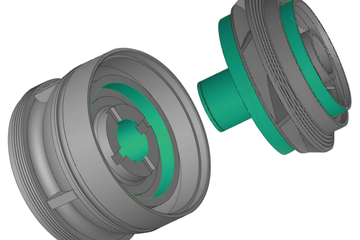

Based on our oilfield-rugged CENtrilift™ electrical submersible pumping (ESP) system design, our horizontal pumping systems out-produce less powerful pumps. This energy-efficient technology can be your best choice for any job involving fluid transfer, fluid injection, and pressure boosting. Regardless of the application—upstream, midstream, or industrial—HPump surface pumping systems help you control fluid transfer costs and protect the environment.

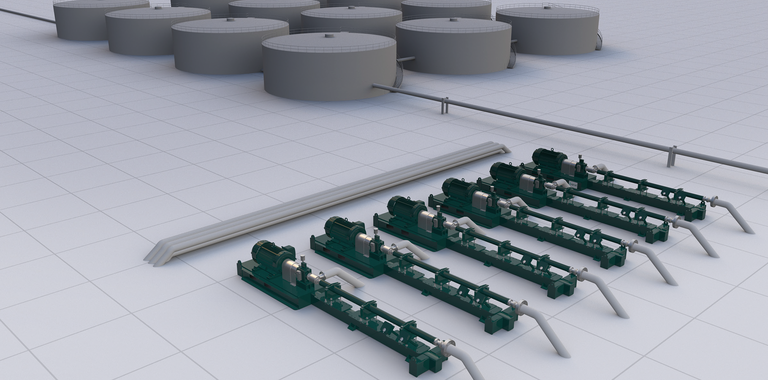

HPump systems combine a multistage centrifugal pump, a thrust chamber, and an efficient electrical motor in a single sturdy skid. This simple design speeds up manufacturing while delivering maintenance cost reductions of up to 88% compared to other pumping systems.

The design is also rugged for installation in unsheltered, unforgiving environments. It can handle hot and cold conditions, hot fluid temperatures, and solids up to 100 ppm.

Our horizontal pump systems are designed to scale up or down depending on your needs. You can easily upgrade and replace what you need with off-the-shelf components, cutting downtime and maintenance costs dramatically. And, if you need additional flow, simply combine multiple HPump systems for greater flexibility.

Contact us today to learn how horizontal pump systems from Baker Hughes can optimize your surface pumping needs.