Highlights

Highlights

Benefits

- Proven designs with high availability, up to 98.8% efficiency, and lower total cost of ownership

- Engineered solutions for any turbine up to 350 MVA including aeroderivative gas turbines, heavy frame gas turbines, steam turbines, and turboexpanders

- Fast startup option for hazardous areas—with no need for purge and pressurization cycle

Features

- Modular generator architecture reduces lead time, and proven designs for custom projects

- Quick installation—rotor is typically installed in unit during transportation

- Flexible heat exchanger options: open air vent, CACA/TEAAC, CACW/TEWAC

Applications

- Industrial

- Oil and gas

- Geothermal

- Concentrated solar

- Independent power producers, utilities

- Mobile

Overview

Overview

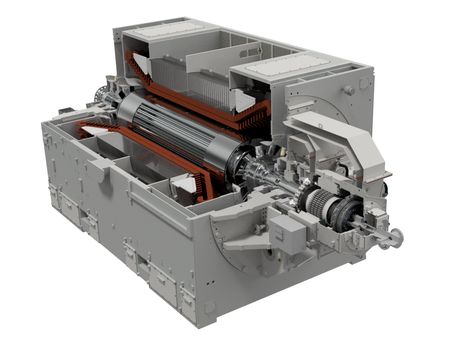

Our BRUSH™ Power Generation 2-pole DAX air-cooled generators can be driven by steam or gas turbines providing power outputs from 20 to 310 MVA (including BDAX with brushless excitation control, and YDAX with brushed/static excitation control). With over 3,500 active installations, our proven units are specified by leading industrialists, EPCs and facility operators.

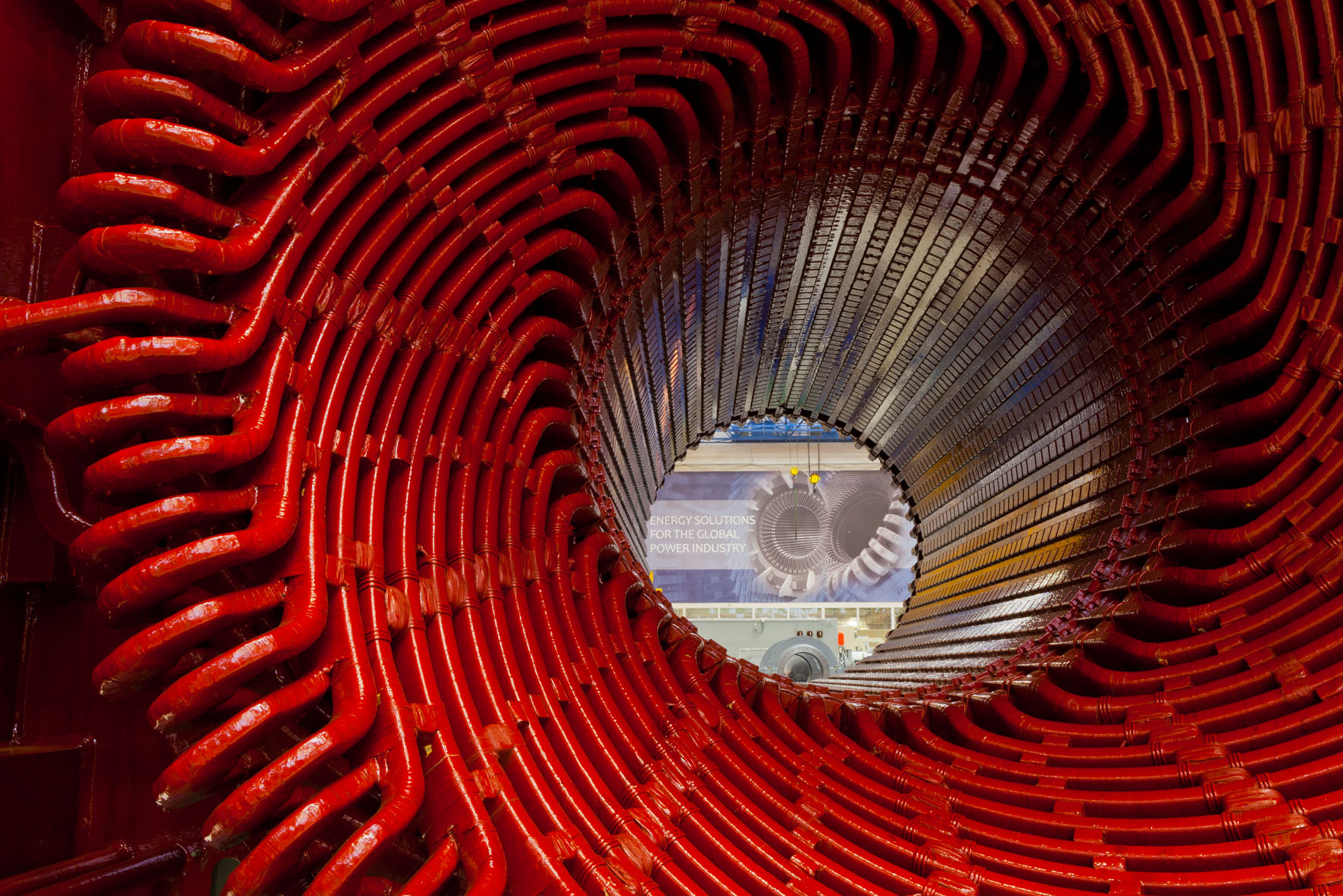

Stator

The stator frame is designed to withstand mechanical stresses under fault conditions. The windings are insulated with a resin-rich mica glass tape that provides excellent insulation performance at temperatures up to class F.

Rotor

The rotor is fabricated from a one-piece forging of degassed nickel chromium molybdenum, which provides excellent tensile properties. The rotor winding conductor material is high conductivity copper/silver alloy strip with each turn insulated with Class F insulation. The end-windings are held in place by retaining rings manufactured from austenitic non-magnetic 18-18 manganese chromium steel.

Excitation

Brushless excitation consists of three-phase, rotating armature, alternating current generator, with a shaft-mounted fused rotating rectifier. An alternative to brushless excitation is static excitation which is accomplished by routing power from the generator through transformers through a controlled rectifier to the main field through slip rings.

Specifications

Voltage

Up to 20 kV

Excitation

Brushless or static

Insulation

Class F

Frequency

50 or 60 Hz

Output

20 to 310 MVA

Drive

Single or double-end drive

Driver

- Aeroderivative gas turbine

- Heavy frame gas turbine

- Steam turbine including geothermal

- Turboexpander

Design standards

IEC, IEEE, CSA, ATEX, IECEx, ABS, DNV and Lloyds compliant

Options

- Low-temperature operation

- Low noise

- Lightweight

- Hazardous area operation

- Multiple heat exchanger options

- Double-end drive

- High inertia

- Low inertia

- Harsh environment

- Capable of synchronous compensator operation