Highlights

Highlights

Benefits

- Our high-efficiency designs ensure optimal refrigeration and expansion energy recover for compression service

- Zero-leakage design with oil or magnetic bearing, including optimized AMB footprint and weight layouts for offshore application

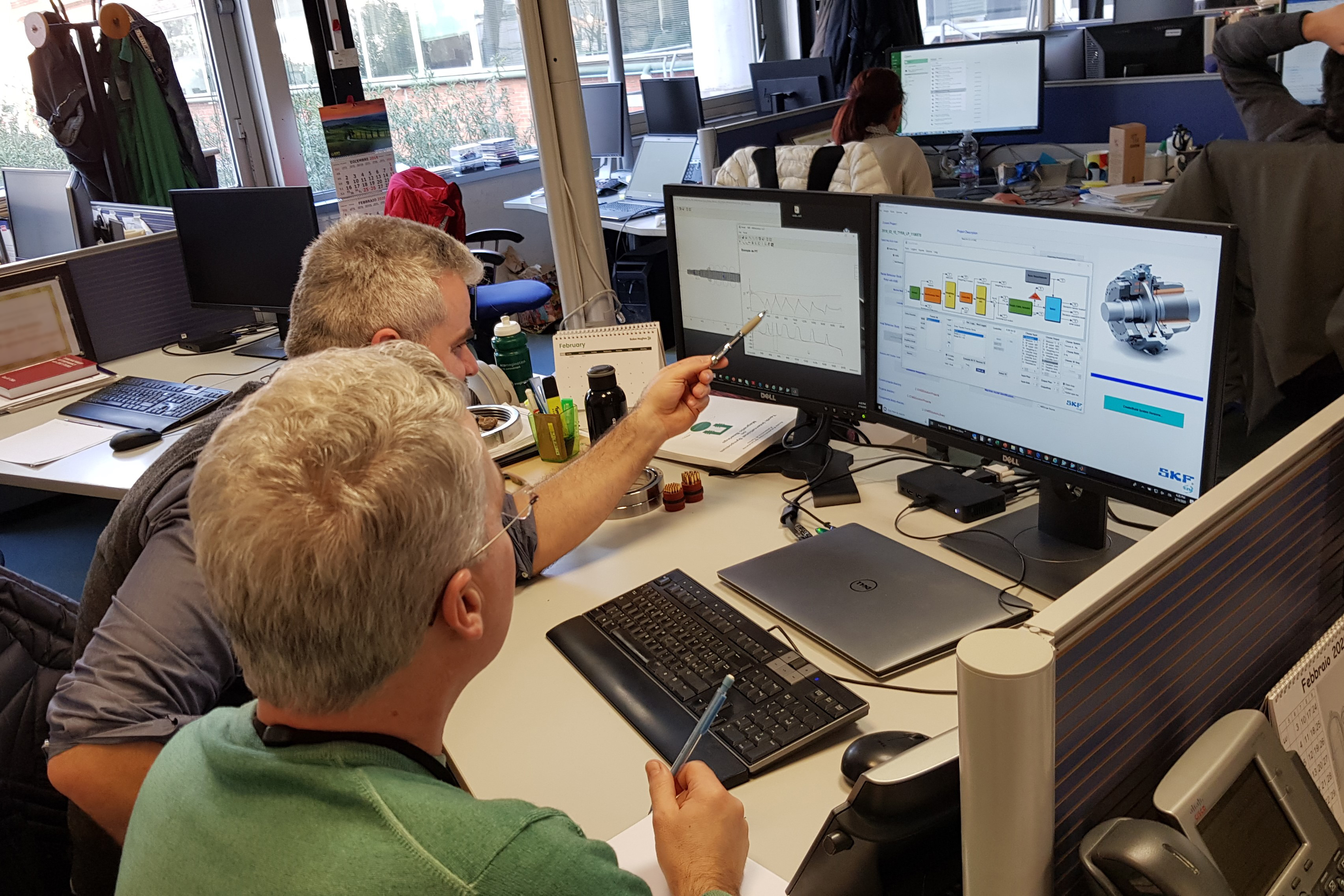

- Strong collaboration with SKF for continuous AMB optimization, enabled the first AMB for 5.5 MW floating LNG

Features

- Advanced and proven design with broad range of verified wheels up to 1,000 mm diameter for large capacity machines

- Wide range of sizes up to 15 MW supported on AMB or oil bearings with optional dry gas seals for aggressive gas applications

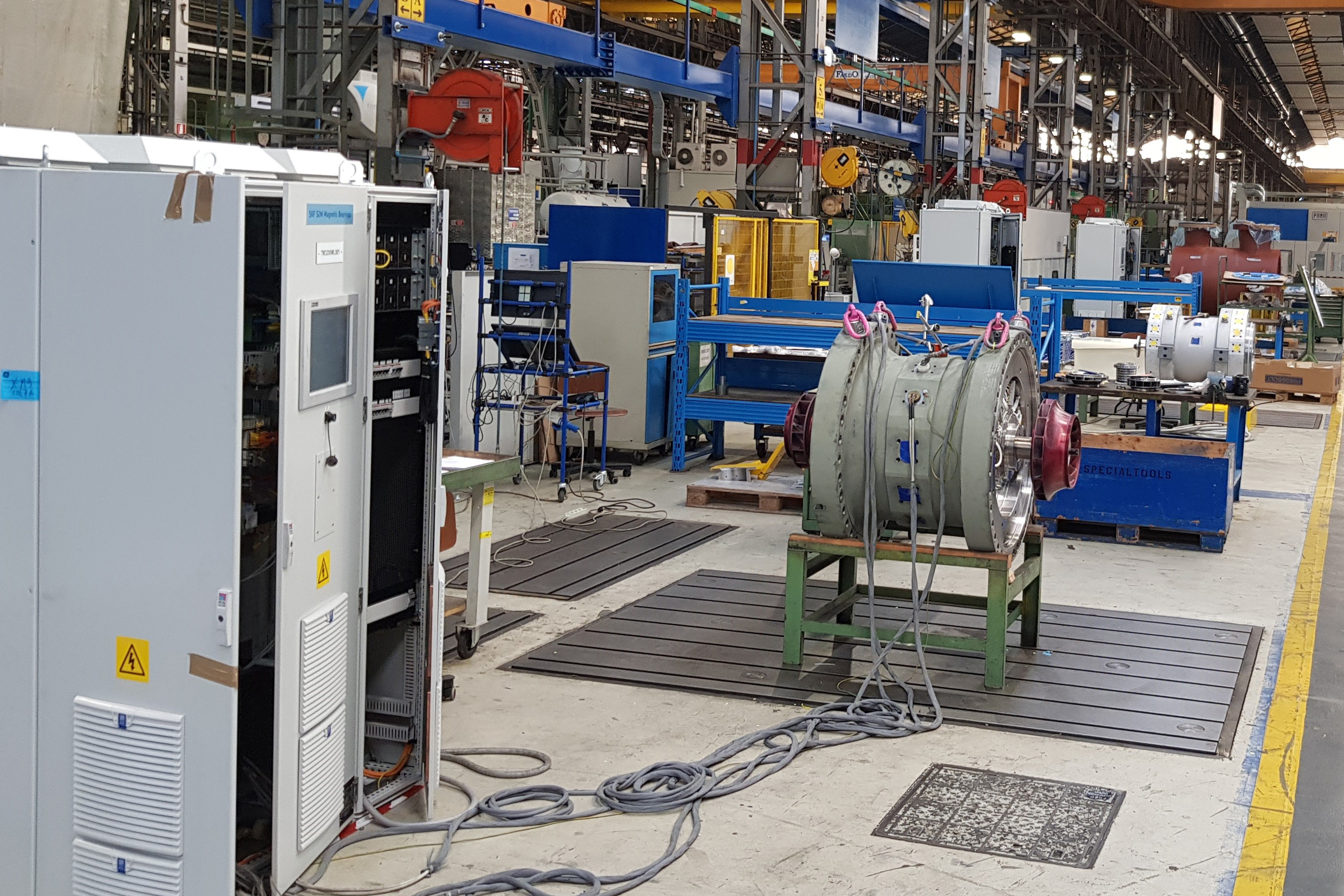

- We can manage all turbomachinery through equipment installation, full-load string testing, start-up, commissioning and service

Applications

- LNG feed-gas treatment (onshore and floating)

- Cryogenic gas treatment: dew point control, LPG recovery, refrigeration

- Petrochemical: ethylene, syngas, H2 rich process

Overview

Baker Hughes's turboexpander-compressors are available in a wide selection of frames and sizes to best match any demanding cryogenic application. Extensive in-field experience and state-of-the-art design features ensure the highest performance for simultaneous refrigeration service and energy recovery.

Complete in-house capabilities

For a 2019 offshore platform project in the North Sea involving seven of our single shaft, high-speed moto-compressors with active magnetic bearings (AMB), we also delivered two AMB expander-compressors with dry gas seals (DGS). Service is characterized by high H2S content not compatible with magnetic bearing. Hence, the DGS solution was the only way to enable oil-free configuration in sour service. The turboexpanders and moto-compressors were completely assembled and tested in-house, leveraging our internal capability for magnetic-bearing tuning and testing resulting from the agreement with SKF.