Technology Sessions

These 1-hour sessions led by Baker Hughes domain experts provided deep dives into a range of our latest technologies and solutions, as well as market and application trends. Some popular sessions this year included turbomachinery solutions for LNG and FPSO, our path to reduce carbon emissions in the oil and gas value chain, and artificial intelligence for digital transformation.

Aptara: modular solutions to radically optimize subsea systems over life of field

Aptara™ subsea system enables a Totex-lite approach to subsea production systems, with 50% lower TCO, through effective life-of field design, unlocking value through increased flexibility. During the session we will present how we have worked with the industry to develop solutions such as the lightweight compact tree, the modular compact manifold, controls and the digital tree cap.

Cogeneration as a flexible way to support energy transition

Cogeneration is one of the most efficient solutions to generate power and heat. The cogeneration sector is investing in new technologies to become more efficient and flexible, and to integrate the fuels of the future. This session will focus on the new technological developments in the cogeneration sector, including hydrogen gas turbines and how they will enable a resilient, decentralized, and climate-friendly energy system.

Collaboration and turbomachinery standardization to optimize FPSOs

This session looks at how Baker Hughes Turbomachinery & Process Solutions (TPS) business is partnering with general contractors and operators to optimize and standardize turbomachinery solutions for FPSOs and meet growing requirements for larger crude oil and gas production, while complying with stringent technical and regulatory requirements for the deep-water industry.

Creating a digital transformation culture

Digital transformation programs require the right people, the right skills, and the right ecosystems of partners. This session explores the ways in which leading operators are tackling culture and talent challenges, from new work spaces and incubators to innovation hubs and education programs for industrial workers.

Driving efficiency, lowering HSE risks through remotely managed drilling operations

Baker Hughes and a key customer will recap the operational results from drilling 50+ directional wells and over 1.5 million feet in the Permian Basin—using both conventional drilling motors and rotary steerable technology. The campaign used no directional drillers or MWD personnel at rig sites—thereby reducing HSE risks, and driving rapid improvements in drilling speed and efficiency. We’ll detail the underlying technology and processes that made these results possible, and discuss how this approach can be expanded upon in the future.

Enabling data-driven production decisions with intelligent completions

The industry is beginning to see the real value that fiber-optic data can bring to operations. As this trend continues, “intelligent” technologies become a critical component in well planning and completion designs. This session will discuss how distributed downhole data and remote-actuated tools can drastically improve to how operators respond to changing reservoir conditions, and further drive full asset characterization.

Flare.IQ: revolutionizing flare system management

Introduction to the Baker Hughes flare management platform designed to lower emissions through improved combustion, protect assets, improve system uptime, and reduce HSE risks.

H2 and carbon capture: drivers for oil and gas decarbonization, enablers for renewables

This session will discuss the role of carbon capture and H2 in decarbonizing upstream (e.g. EOR and blue-hydrogen) and downstream (e.g. e-fuels, green ammonia) sectors, and in renewables to enable green H2 production. We’ll also look at challenges for adoption at large scale.

Immediate shareholder value through novel plug and abandonment technology

Recent Baker Hughes technologies and techniques have radically streamlined P&A operations to significantly reduce overall project costs. This new portfolio enables operators to establish a new baseline cost for well abandonment and decommissioning—resulting in a significant improvement to the customer’s bottom line.

Industrial transformation is here: case studies of process plants realizing savings through digital valves

This session covers our Valve Lifecycle Management (VLM) platform for plant startup and commissioning, operational optimization, and turnaround management. Case studies explore where customers have recognized savings and efficiency gains by using VLM. We’ll analyze the profit impact of improperly tuned control valves, see how VLM’s early detection capabilities minimize costs, and identify the critical 3-4% of valves in a fleet that need immediate attention.

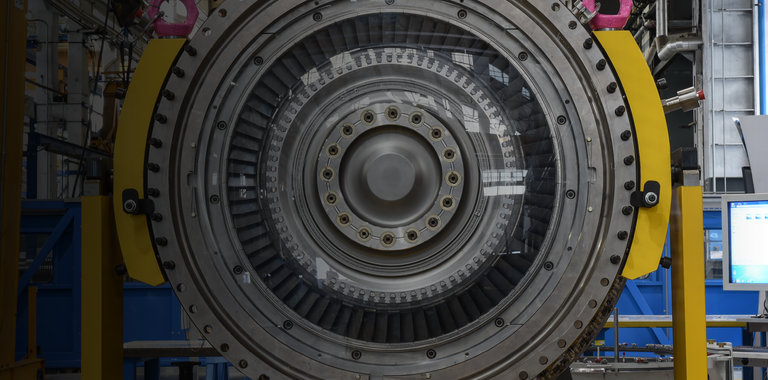

Innovations and advanced manufacturing for turbines and compression solutions

Our Turbomachinery Process and Solutions (TPS) workshop in Florence meets the needs of various segments, including onshore and offshore production, LNG, pipeline, refining, petrochemical, and industrial. You’ll see how the digital revolution is affecting how we design, manufacture, and service turbines and compressors. The tour includes additive manufacturing, sensing, advanced materials, and combustion laboratories that complement our dynamic manufacturing techniques.

Innovations in pipeline pre-commissioning to drive safe and efficient installation

The session will showcase our collaboration on the Turkstream offshore pipeline project, looking at how our latest pipeline pre-commissioning solutions, including innovative dry pre-commissioning, contribute to overall project value.

LM9000 and aeroderivative gas turbine technologies

Our turbomachinery facility in Massa focuses on packaging and machining of turbocompression technologies. The facility host automated manufacturing lines, as well as advanced assembling and testing areas. This tour includes a visit at the test bed dedicated to the 67MW+ LM9000 gas turbine, the ideal equipment for LNG mechanical drive. As part of the campus visitors will see the service shop completely dedicated to aeroderivative gas turbines. Total duration is about 4.5 hours including transportation.

LNG solutions to reduce costs and environmental impact

Traditional LNG models are evolving, with players expanding across the value chain, and new business models appearing. More attention on the environment, faster time to LNG, flexibility, and cost-per-ton reduction are key factors driving project development decisions. This session provides an overview of LNG market trends, new business models, and ways technology can cope with the challenges of meeting future demand and environmental regulations while reducing total cost of ownership. Modularization, standardization, driver efficiency are key topics.

Make your turbomachinery and plant more profitable thanks to advanced digital services

Unparalleled Baker Hughes digital offerings turn big data into smart data by enabling reinforced intelligence processes through OEM-based analytics, deep learning methodologies, and engineering/industry expertise from our Turbomachinery & Process Solutions (TPS) Service Engineering department. We create high-fidelity digital twins and associated services in continuous collaboration with operators and their organizations to improve reliability and performance up to plant level.

Reducing Pipelines carbon footprint: solutions to enhance efficiency and productivity in Midstream

As energy demand keeps growing, traditional fossil fuels must prove their sustainability. Pipeline and storage operators already face increasing challenges such as complex safety and environmental regulations. Alternative fuels such as hydrogen and syn-gases are re-shaping the industry’s future. Baker Hughes has innovative solutions to help midstream project developers and operators increase efficiency and productivity, while driving safety and eliminating emissions.

Scaling AI for safer, cleaner, more efficient energy

Speakers from the BakerHughesC3.ai joint venture and Microsoft explore the potential impact for equipment and process reliability, production optimization, energy management, and overall use of big data for predictive intelligence.

Storage Connect: an integrated solution for faster, safer, more reliable underground gas storage

This interactive technical workshop will explore the major challenges for UGS development, and discuss how Baker Hughes technologies (which are used in more than 80% of underground gas storage (UGS) facilities worldwide) can radically transform the economic and technical business drivers—reducing project risk, cost, and development time; while maximizing deliverability and working gas capacity.

Subsea technologies that enable reduction in topside infrastructure and carbon footprint

This session will highlight the latest innovations in subsea processing and all-electric systems and the industry challenges these solutions are addressing . Solutions highlighted include: all-electric subsea production system, a barrier-fluid free modular compact pump, and an innovative chemical-free seawater treatment solution.

The Fourth Industrial Revolution: technology for the next phase of industrial automation

The next phase will see an integration of intelligence at the edge, and scalable artificial intelligence. With high-fidelity sensors and edge analytics, it won’t be long before we see controls systems, manufacturing, and closed-loop automation. Enabled by machine and deep learning, systems can automate to become safer, more reliable, and more efficient.

The path to Net-Zero: a comprehensive roadmap for quantifying, goal-setting and reducing carbon emissions in the oil and gas value chain

This workshop will take a comprehensive look at building and enhancing corporate emissions reduction programs. The session will discuss quantification and goal-setting, and technical case studies for tackling the largest categories of oil & gas carbon emissions: flaring, venting & fugitive emissions, power generation and energy use. Bring your ideas for a lively discussion and sharing session.

Unlocking previously unproducible reservoirs with new drilling liner technology

Conventional drilling and liner technologies did not allow ConocoPhillips to access the reservoir through the highly unstable overburden section on the Greater Mooses Tooth project in Alaska. This technology gap would not allow successful completion of development wells. But recent advancements have made it possible to drill, evaluate, and place a liner in a single run, enabling cost-efficient development in the most difficult drilling environments. In this session, Baker Hughes and ConocoPhillips will discuss how the first deployment of a new-generation steerable drilling liner with LWD helped unlock the energy potential of a critical asset in ConocoPhillips’ Alaska portfolio.