Executional excellence around the world

At Baker Hughes we offer global support with a quick turnaround time, ensuring your operations run smoothly and efficiently. As the original designers of the equipment, we understand it better than anyone else. With access to all engineering know-how and original drawings, our team is uniquely qualified to maintain and service your equipment to the highest standards.

With OEM-trained engineers stationed worldwide and spare parts ready 24/7/365, we provide unbeatable response times, unrivaled knowledge, and global reach.

All our support packages (including performance plans, maintenance parts kits and inspection plans) can be tailored to your specific requirements.

Our Aftermarket Services

Field Service

Our Field Service Engineers are specifically trained on BRUSH Power Generation equipment, following a meticulous maintenance schedule designed to maximize performance and minimize downtime. Plus, our exclusive RoGIS inspection process provides a thorough assessment to ensure your equipment remains in peak condition. When you choose our Field Service Support, you're choosing expertise, reliability, and excellence.

- Stator end winding refurbishment

- Stator overhaul

- Stator rewind

- Rotor-end/retaining rings inspections

- Bearing replacement

- Oil seal replacement

- Cooler repair

- AVR health checks

- AVR Tuning

Repairs

Reliable On-Site and Off-Site Repair Services to Minimize Downtime

The quickest way to keep your installation or equipment running smoothly is to perform repairs—major or minor—on-site whenever possible. With our proactive maintenance and inspection services, we can often identify potential issues before they become critical, allowing us to schedule necessary repairs in advance and minimize unexpected outages and downtime.

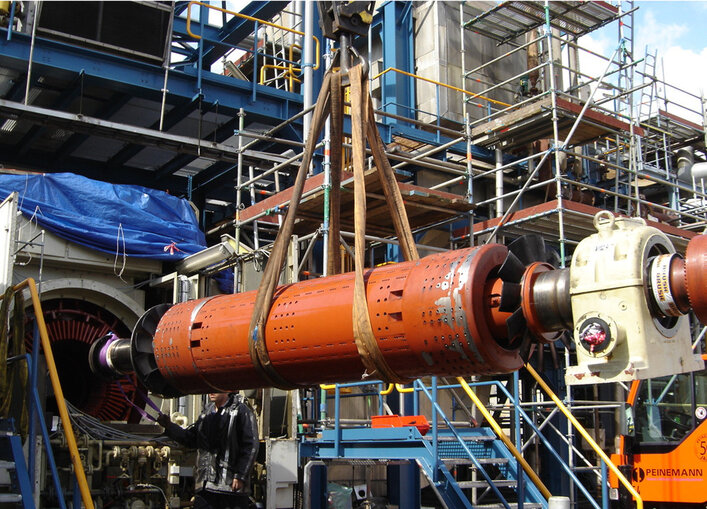

When on-site repairs aren’t feasible due to space limitations, unsuitable environments, or lack of resources, we ensure seamless transportation of your equipment to one of our specialized factory facilities at our manufacturing bases.

We have wo OEM Level Service Centers: Europe: Plzen, Czech Republic America: Pittsburgh, Pennsylvania

Our comprehensive repair services cover a wide range of needs, including generator and controls field repairs, service shop repairs, high-speed balancing, and repairs for equipment from other OEMs. You will get the expertise and flexibility needed to keep your operations running without interruption.

Parts

Extend the Life of Your Equipment with Our Premium Replacement Parts

Maximize the performance and longevity of your equipment—whether manufactured by us or another original equipment manufacturer (OEM)—with our comprehensive replacement parts support service. We provide a complete range of high-quality components, from essential individual items like diodes and fuses to integral parts such as wedges, coils, laminations, and retaining rings. We also offer major equipment assemblies, including replacement rotors, stators, and exciters, which are designed to be mechanically and electrically interchangeable with your existing equipment.

Our replacement parts are engineered to ensure perfect fit, form, and function, maintaining the reliability and efficiency of your machinery. With worldwide availability, we offer everything from essential components like keys, spools, and bearings to critical parts that keep your operations running smoothly. Choose our replacement parts service to extend your equipment’s life and maintain peak performance wherever you are.

Capital Spares: Tailored Solutions to Minimize Downtime

We offer capital spares designed to minimize downtime and keep your operations running smoothly. Our capital spares include critical components such as spare rotors and stators, which are custom-built to meet your specific needs. Unlike off-the-shelf parts, these are made-to-order, ensuring that each component is crafted with precision to match your exact specifications.

By opting for our capital spares, you benefit from a streamlined replacement process. When a component needs to be replaced, we provide a high-quality, custom-built spare and handle the swap out efficiently, reducing the impact on your operations. Our approach not only helps you avoid prolonged outages but also ensures that your equipment performs reliably over its entire lifecycle.

Service24 - Supporting you 24/7/365

Service24 provides end users and channel partners with 24/7/365 access to our BRUSH Power Generation trained engineers who know the machines inside and out.

Service24 improves response time for operational technical assistance and emergency machine breakdown support.

Florence Training Center

Welcome to our Florence Training Center, where we provide hands-on training designed to give you all the information you need to operate, maintain, and optimize your equipment confidently. Our immersive, practical training sessions offer a unique opportunity to learn directly from experts, gaining the skills and insights required to get the most out of your equipment. At Baker Hughes we believe that the best way to ensure your success is by sharing all the knowledge and expertise we have to offer about BRUSH Power Generation products and solutions.

Find out more by contacting your Regional Sales Manager.