Overview

Challenges

- Deploy the completion to depth successfully ensuring all tools operate as designed

- Provide reliable isolation and integrity downhole to successfully execute the frac job

- Reduce the risk of losing stages due to hole stability issues causing casing deformations

- Improve the completion efficiency by increasing the stage count per day compared to a plug-and-perf operation

- Avoid long well interventions to mill frac plugs

Results

- Deployed a total of 74 sleeves covering the horizontal section of the well, the longest FracPoint cemented MP system in Latin America

- Performed an average of 8.1 frac stages per day as compared with the 6.8 using conventional plug-and perf completion methods

- Achieved a record of 9 stages in a day

- Eliminated the need for wireline during frac operations, saving time and costs

- Reduced risk associated with having simultaneous operations and more personnel involved in the frac operation

- Delivered reliable solution for hole stability issues during frac operations

A customer operating in the Vaca Muerta formation in the province of Neuquen, Argentina, needed to hydraulically fracture two wells as efficiently and cost effectively as possible. The operator wanted to improve the frac performance that the traditional plug-and-perf technique delivered, and reduce the risk of losing stages due to casing deformations caused by well stability issues during the frac operation.

The operator faced limitations to frac a lower number of stages per day due to the time spent in intermediate operations needed for plug-and-perf. The deployment of frac plugs and contingencies like coiled tubing interventions needed on the plug-and-perf technique combined to reduce the efficiency of the completion, compounding in too much time and money needed to complete the wells. In addition, wellbore instability that could potentially collapse or deform the casing during frac operations or outright losing stages proved too great a concern with the conventional plug-and-perf technology.

To compare fracture completion technologies, the location also included two other wells that were planned to be completed using the plug-and-perf technique.

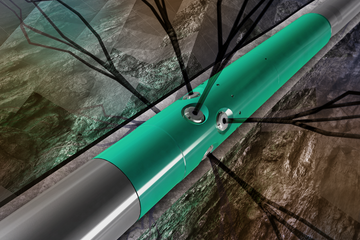

With extensive experience in the country deploying frac sleeve systems, Baker Hughes recommended the FracPoint™ Cemented MP system, which provides a multi-stage cemented completion consisting of an Adjustable Alpha Sleeve™ pressure-actuated toe sleeve and 72 FracPoint™ Cemented MultiPoint ball-actuated sliding sleeves covering 7,546 ft (2300 m) of horizontal section. The robust ball-actuated FracPoint MP sleeves provide multiple entry points per stage to maintain the limited entry design the operator used with the plug-and-perf technique but enable a much more efficient hydraulic fracturing operation. Because there is no need for firing perforation guns, setting frac plugs, or pulling out of the hole with the wireline assembly after setting the frac plug, the ball-actuated frac sleeves save significant time. The dissolvable frac balls eliminated ball pileup in the pipe during production and subsequent production loss and wellbore intervention.

Download the PDF to read the full case study.