Overview

Challenges

- Conventional cased-hole workover options had become uneconomic

- Multilayer reservoir with significant variance in thickness of sand layers

- Wells required sand control and isolation of gas-water contacts

Results

- Provided an effective alternative to single trip multizone operations

- Completed three zones in a single trip

- Reduced operational time by six days, saving $4.8M USD

- Enabled precise zonal isolation and selective production

- Enabled economic, high rate sand-free production of gas

An operator in Indonesia had completed 11 wells in a deepwater multi-layer gas reservoir using conventional cased-hole multizone gravel packing operations. They were looking for an economical single-trip solution that would offer similar or better sand control productivity, despite having intervals of varying lengths.

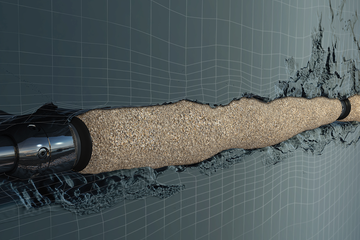

They reached out to Baker Hughes to explore utilizing the GeoFORMTM conformable sand management system. The GeoFORM system was successfully deployed by the same operator in the Adriatic Sea to realize significant efficiency gains and reductions in rig time. The GeoFORM system’s modularity and flexibility lets you customize the completion and stimulation design to best match the reservoir. Unlike conventional sand control techniques, the GeoFORM system leverages unique shape-memory-polymer (SMP) material— a filtration media that expands downhole and conforms to the borehole wall. GeoFORM system deployment is faster and offers much greater completion design flexibility compared to conventional multizone gravel or frac-pack completions.

Download the PDF to read the full case study.