Overview

Challenges

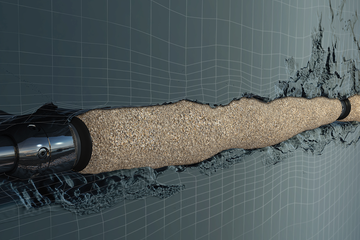

- Extremely unconsolidated methane hydrate formation

- Broad range of particle sizes from 20 to 200 μm

- Ongoing wellbore subsidence

- Low BHT of 32 to 54°F

- Test well located in water depths in excess of 3,300 ft

- Conventional sand control methods had failed in previous tests

Results

- Enabled longest-ever sand-free production test in methane hydrate

- Produced up to 0.5 MMSCFD of gas and 3,100 BPD of water

- Avoided known failure risks associated with conventional sand control methods

- Eliminated gravel packing logistics and risks

A customer that had drilled a new test well in methane hydrate off the east coast of Japan was in quest of a viable sand control solution following a 2013 production test that was terminated after only six days. The 2013 test well, which had been completed using the most widely relied on sand control method—gravel-packing—had quickly succumbed to sand production. In early 2014 a collaboration began between the customer and Baker Hughes to identify a solution that could enable sustained sand-free production from the challenging reservoir type.

The new project began with a close evaluation of the 2013 production test. The teams found that when the well was brought online, the wellbore enlarged from 8.5 to 12 in. (21.6 to 30.5 cm) as the formation depressurized. This caused the gravel in the annulus to shift, exposing the underlying sand control screen which quickly began to erode. Sand particles smaller than 100 μm entered the production string through the compromised screen, ultimately resulting in equipment failure.

Download the PDF to read the full case study.