Overview

Challenges

- Increase gross tripping performance in an already highly optimized operation

- Avoid swab and surge

- Minimize health, safety and environmental (HSE) risks

Results

- Saved 13.8 hours vs. plan for section

- Increased openhole running speed from 414 to 889 m/hr (1,358 to 2,916 ft/hr)

- Saved >$180,000 USD for the operator

- Experienced zero swab/surge incidents

- Delivered superior HSE performance

A European operator working in the North Sea’s continental shelf was looking for new ways to add incremental value to a development campaign that was already operating at a high level of efficiency. The Baker Hughes Integrated Well Services Team partnering with the operator on the well construction program proposed the i-Trak™ drilling automation service that incorporated the JewelSuite™ 3D Geomechanics software.

Deployed digital twins to optimize tripping speeds

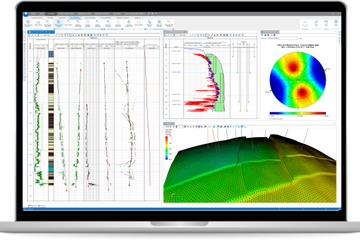

As part of the i-Trak service, the Baker Hughes team deployed a real-time digital twin that was pre-loaded with the JewelSuite software’s earth-model-derived boundary conditions including pore, collapse, and fracture pressures. The software drilling engineering package also incorporated the rig equipment’s mechanical constraints in order to be able to automatically deliver the optimum tripping velocity based on the current bit depth. The optimum value was dynamic, adapting to operational states such as pumps-off tripping, pumps-on tripping, or reaming operations. The i-Trak service provided the Baker Hughes engineers with this optimum speed and automatically alerted them, via an intuitive user interface, if the actual the observed speeds dropped below the optimum tripping speeds.