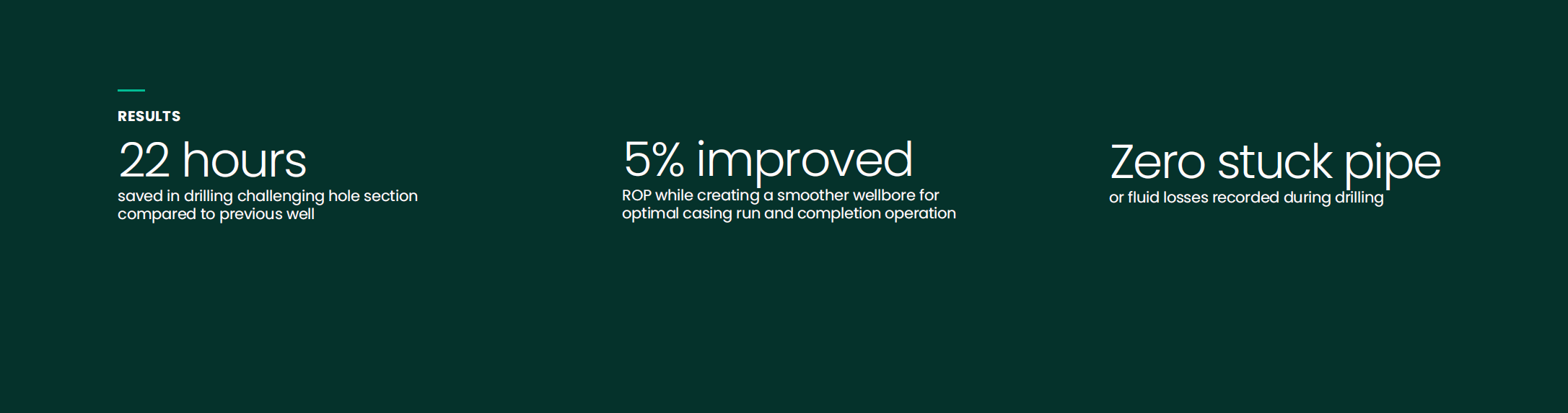

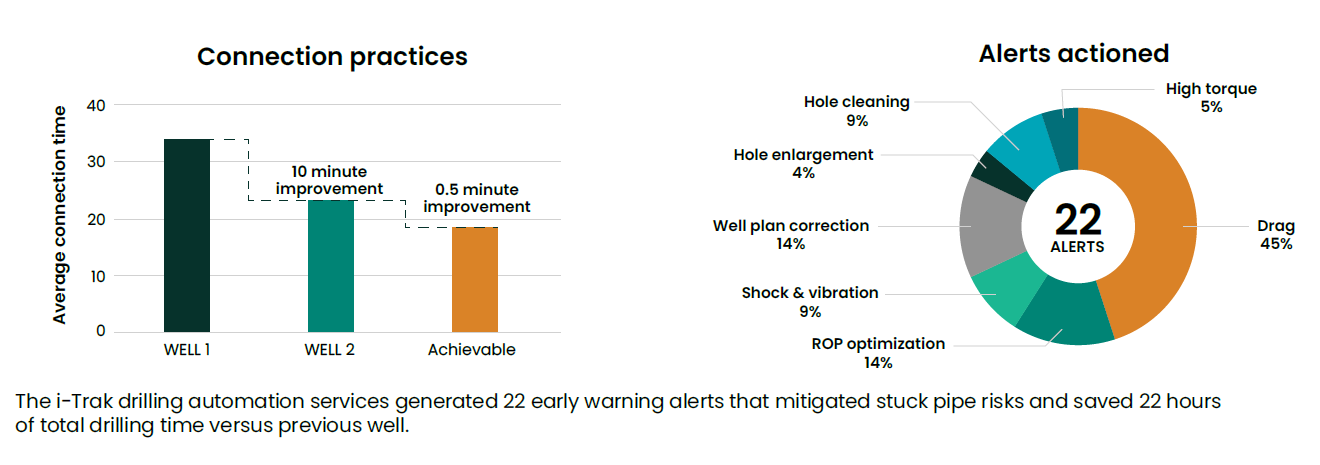

i-Trak drilling automation services maximize ROP and save 22 hours in challenging hole section

Jul 13, 2023

Drilling in carbonate formations presents several challenges:

Deployed i-Trak™ drilling automation services in advisory mode in the Baker Hughes Remote Operations Center