Overview

Challenges

- Deepwater FPSO vessel operating below capacity due to an out-of-service compressor module

- Maintenance activities for compressor modules to be conducted in limited space with several obstacles

- Lifting plans for handling removed parts on compressor deck

Results

- 50% higher reliability

- Technology upgrades including new control systems, and improved material storage

- Dedicated maintenance procedure ready for future outages including unplanned events

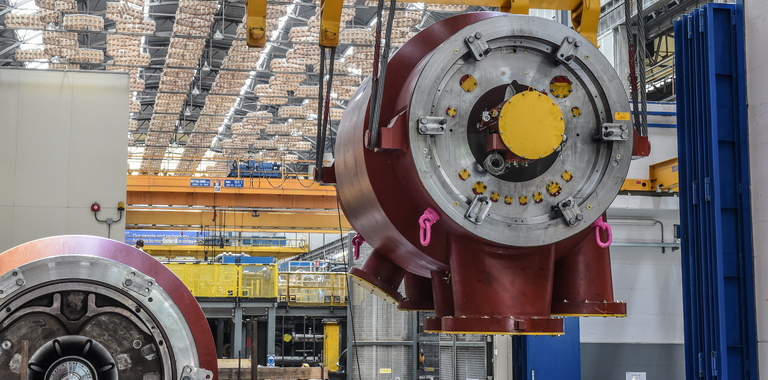

The Baker Hughes Advisory Service team was engaged to inspect the turbomachinery fleet installed a floating production, storage and offloading (FPSO) vessel moored in 1,100 m depths at one of western Africa's largest fields. Our task was to produce a tailored report providing improvements for fleet maintainability and serviceability.

The main objective was to provide technical advice for two compression trains, each composed of three centrifugal compressors driven by electric motors. Train A had not operated for a few years, and Train B had been running below its full production capacity for the last eight years due to production plant constraints, including different operating conditions, different process gas source and composition.

Our report identified key technical findings and upgrade opportunities, and detailed a restoration plan to optimize production and improve reliability.