The United Nations advises greenhouse gas (GHG) emissions must fall by 45% this decade to achieve net-zero emissions by 2050 and to keep global warming to 1.5°C or less.

This is the case for the Scope 1 and 2 emissions resulting from the production, transportation, and processing of hydrocarbons – which account for 5.1 billion tonnes of greenhouse gas emissions annually, according to the International Energy Agency (IEA). Methane is one of the most potent forms of emissions from the oil and gas industry, responsible for around 30% of the rise in global temperatures since the industrial revolution[1].

Considering this, the field of emissions abatement – the detection, reduction, and ultimately prevention of greenhouse gases – has been cast into the spotlight. The good news is the tools and technology are readily available now. In fact, the IEA said that 80 Mt of annual methane emissions could be avoided through the deployment of known and readily available technologies, at either low cost or net positive return on investment.

The industry has an obligation to act and the means to do it. There is no excuse.

Ilaria Parrella, Emissions Abatement Director, Baker Hughes

However, the road to emissions reduction is not always straight forward. To understand how to use these technologies to abate emissions, the Energy Forward Stories team sat down with Ilaria Parrella, Emissions Abatement Director at Baker Hughes. In this article, she breaks down the different emissions sources, why they matter, and how to tackle them.

1-Flaring

The controlled burning of natural gas associated with oil and gas production.

Flaring is typically done for a few reasons: 1) managing waste gas that can’t be captured or processed (routine); 2) due to equipment and process requirements (non-routine); or 3) to release pressure for safety reasons.

Why it matters?

- In 2023, around 148 billion cubic meters of gas was flared globally, resulting in over 350 million tons of CO2 equivalent emissions[2].

That’s on par with the emissions that would come from 75.5 million passenger vehicles being driven for a year, according to the US EPA Calculator.

Ilaria Parrella, Emissions Abatement Director, Baker Hughes

Reference: US EPA Calculator

- A large portion of that un-burnt gas is methane. Rapidly reducing methane emissions is regarded as the single most effective strategy to keep the goal of limiting warming to 1.5˚C within reach[3].

- Flaring also wastes valuable natural gas resources that could be recovered and monetized.

How do you combat flaring?

- Technology: Using existing, cost-effective technologies that are available today, companies can reduce flaring, while creating value from the gas that would have been wasted by turning it into to power, fuel, or feed-stocks. This starts by having a better understanding of your flaring emissions through a continuous monitoring system. For example, bp conducted one of the largest ever full-scale studies of flare combustion efficiency using real-time data.

- Collaboration: Companies across the sector, including Baker Hughes, have made public commitments to eliminate routine flare emissions by 2030 and to work together on solutions. However, the key is turning these commitments into action.

- Action: Late last year at COP29 in Azerbaijan, SOCAR and Baker Hughes did just that, announcing a project to deploy an innovative gas recovery and hydrogen sulphide (H2S) removal system that will significantly reduce downstream flaring at the Heydar Aliyev Oil Refinery in Baku.

The project is expected to recover flare gas equivalent up to 7 million Nm3 of methane per year, and further reduce CO2 emissions by up to 11,000 tons per year.

Ilaria Parrella, Emissions Abatement Director, Baker Hughes

2-Venting

Unlike flaring where gas is burned, venting is the release of un-ignited waste or excess gas directly into the atmosphere either by design or due to a malfunction. Vented gas is invisible to the naked eye.

Why it matters?

- Venting primarily releases methane, but other harmful pollutants may be present.

- Directly releasing methane into the atmosphere is very environmentally damaging. Over a 20-year period, methane is about 80 times more potent than CO₂ in terms of its global warming potential.

How do you combat venting?

- Getting to the source: Operators need to start by identifying the source of vented emissions and then bring in specialists who can identify appropriate solutions.

- Innovative applications of existing technology: This includes changing wet to dry seals with an upgrade kit, capturing emissions and re-injecting into production using a gas recovery skid, or use of low-bleed valves, to name a few examples.

46% of global venting is estimated to come from gas pneumatic valves and controllers and 23% of onshore methane emission are from compressors.

Ilaria Parrella, Emissions Abatement Director, Baker Hughes

3-Fugitive

The unintentional escape of gases into the atmosphere, which are often due to equipment leaks, old infrastructure, poor design, or inefficient equipment.

Why it matters?

- By their nature, fugitive emissions are extremely difficult for operators to manage.

- This blind spot not only has environmental implications, but it also causes poor efficiency and high operational costs to carry on for long durations of time.

How do you combat fugitive?

- Inspect, detect, and fix: Due to infrastructure deterioration, finding and fixing fugitive emissions requires consistent attention.

- Inspection and integrity services can help operators identify, eliminate, and prevent emissions, while bringing operational efficiencies and cost savings.

Technology: Another way is by using certified low-leak valves, such as the Masoneilan Camflex GR control valves that are designed to significantly minimize fugitive emissions

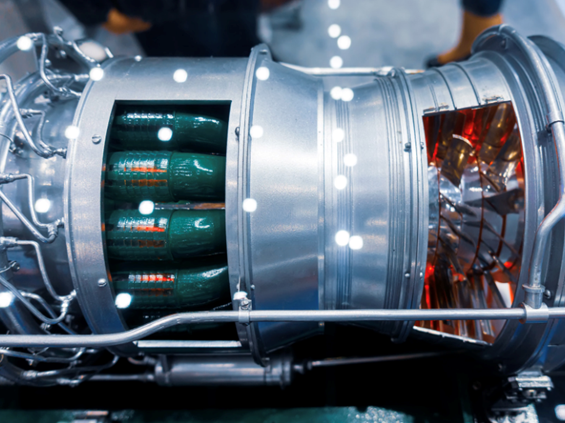

4-Combustion

Equipment used in upstream operations, such as diesel engines or gas turbines, burns fuel which releases combustion emissions.

Why it matters?

More than 50% of emissions sources in oil and gas are from combustion and contain a range of powerful pollutants such as carbon dioxide, methane, nitrogen oxide, and sulphur dioxide[3].

How do you combat combustion?

- Change: Replacing combustion engines with electric systems, such as the electric liquefaction systems (e-LNG) being installed at the ADNOC Ruwais facility in the UAE.

- Improve: Using advanced digital solutions to understand and improve equipment efficiency.

All four types of emissions – flaring, venting, fugitive and combustion – can, and must be stopped if emissions are to be reduced by 45% this decade.

Baker Hughes is embracing that challenge and has stepped forward to bring progress at scale – through experience, collaboration, and innovation.

To hear further insights about emissions abatement listen to these recent conversations with Ilaria Parrella, Emissions Abatement Director at Baker Hughes, Lauren Ward, Senior Low Carbon Program Coordinator at OGCI, and Emmanuel Corral, S&P Global Commodity Insights Senior Emissions Insight Analyst. Click for webinar 1 and webinar 2.

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.