How Sarir Oil Operations used Leucipa across 100+ wells to optimize production from 38,000 to 58,000 barrels a day, while enriching the professional fulfilment of its engineers.

Data is a remarkable asset, empowering humans to arrive at more intelligent, timely, and precise decisions. It can help optimize all kinds of processes, including engineers overseeing oilfield production. However, bringing industrial data together from disparate platforms to be truly useful can be very challenging.

That was the challenge Ahmed Swedan was facing as reservoir engineering manager for Libya’s Sarir Oil Operations B.V. (SOO). Libya was on a mission to increase production output by 2 million barrels per day over three years, and SOO was tasked with playing its part. Swedan believed the data coming from their existing wells would show the way to higher production, but wrangling it was tough.

“We went on a long journey searching for a solution that can gather data from different sources, different formats, and integrate them in one platform to offer us insights,” says Swedan from SOO’s headquarters in Tripoli, Libya. “The ultimate goal was to make the right decision at the right time.”

SOO engineers had access to a great set of data from several oilfields. However, they found they were spending about 70% of their time assembling, quality-checking and integrating it with various software solutions and only 30% on the much more valuable work of analyzing, interpreting and making decisions based on the information.

Using multiple industrial software solutions caused several issues for Swedan’s team, included losing data accuracy as it was exported across siloed systems, compatibility problems, having to learn several applications and paying the maintenance fees for each one of them. The primary obstacle was identifying a solution capable of efficiently aggregating data from disparate sources and formats and readily interfacing it with any application.

Harnessing data to uplift operations

In 2023, Baker Hughes began working with SOO to deploy its Leucipa™ automated field production solution for production optimization and data integration.

“With gas-lift optimization, injecting gas into the oil enhances oil recovery. However, this relationship isn't linear. While a higher gas injection rate initially means more incremental oil, there's an optimal injection rate. Injecting beyond this limit diminishes oil production,’’ explains Swedan. “When you have 100 wells, you would need tedious work to analyze each well every day to get to this point and not exceed it. That’s not possible – you need a system working in the background to give you this crucial information.”

Leucipa provided the ideal solution for this challenge.

“We connected Leucipa to SOO’s data and their workflows to automate the optimization across the oilfield,” says Sebastiano Barbarino, digital production solutions leader with Baker Hughes’ Oilfield Services & Equipment segment. “Every morning, the system gives their production engineers recommendations for them to assess and apply.”

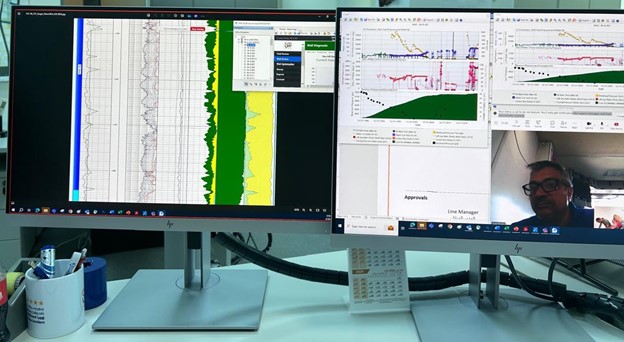

The beauty of this automation is that the alerts are presented to the engineering team via a series of real-time dashboards, integrating continuous surveillance, analytics and optimization in a single solution. Leucipa also allows evaluation of multiple scenarios for optimum field development.

“Leucipa is a single solution that can gather the data from different sources in different formats and integrate it in one platform so that our engineers can leverage the insights,” says Swedan. “We follow the 4R approach: Bring the right data at the right time to the right people in order to make the right decisions.”

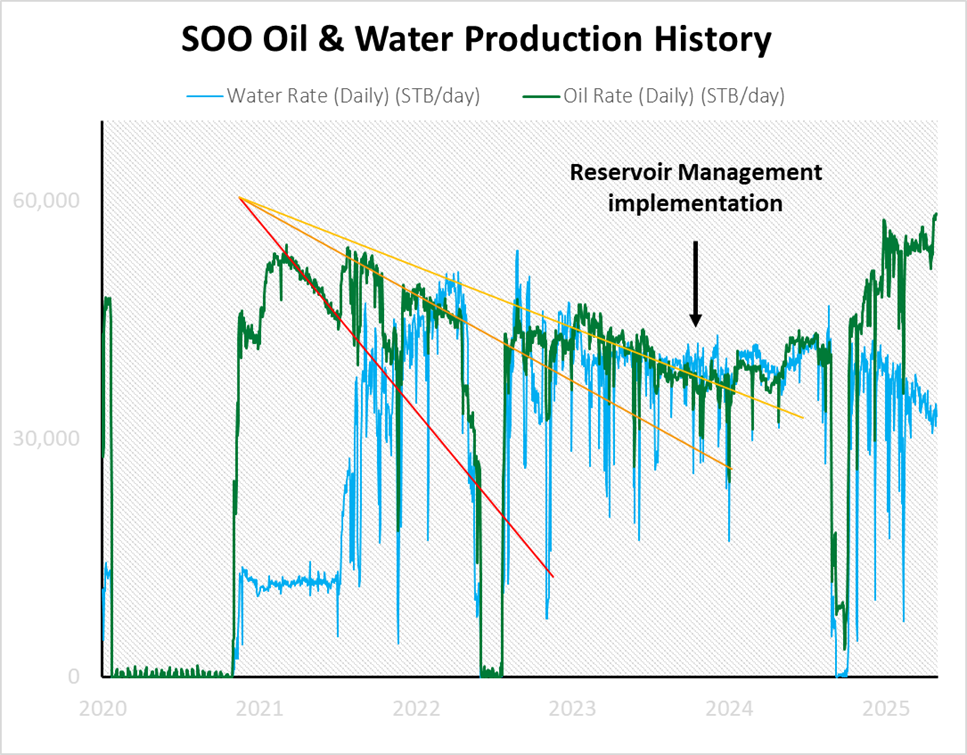

Within two months, the time reservoir engineers dedicated to assembling versus analyzing data flipped, and they now spend at least 70% of their time gaining actional insights. The decisions they then were able to make led to a huge increase in oil production. SOO went from 38,000 barrels a day to 58,000 barrels a day, around half of which was delivered through data integration and optimization using the Leucipa solution integrated with other industrial applications.

Helping engineers do what they do best

The models in Leucipa use data from across the oilfield for rigless intervention and optimization.

“The engineers come in early in the morning and instead of going through the data of 100 wells and trying to locate the issues, Leucipa gives you an alarm. For example, it shows you three wells that are not doing well, so you focus on those,” says Swedan. “With gas-lift, sometimes you try to equalize the gas across wells, and you find out that one well is producing two barrels extra if you inject more gas, and another well is increasing by 200 barrels with the same amount of gas injection. It’s practical to allocate the gas where it’s promoting production, rather than equalizing. It can be easily achieved if utilizing the right system and tools.”

The Leucipa models deployed for SOO in this project are all physics-based, rather than AI or ML-driven. “Leucipa provides recommendations to guide the engineers to the right optimization approach; additionally, it shows them which wells are behaving differently or have a problem for them to go and do the analysis and make their decision,” says Barbarino. “Now that they have all that time back from not having to gather and process the data, the operations team has the time to spend doing much more valuable engineering work. You hire engineers to do engineering, not data management – Leucipa helps them to do what they do best.”

Like SOO’s oil production, Swedan says the job satisfaction of his team is up. “Our people react to that data to make better decisions faster and propose effective plans.” Swedan was a champion for Leucipa from the beginning. “Ahmed really understands the two sides – digital and engineering,” says Barbarino, himself a reservoir engineer. “We know the problems our customers face as operators, and we set out to build something that was useful.”

The Baker Hughes team was able to deploy the Leucipa solution for SOO without once traveling to Libya. This is another achievement Barbarino attributes to Swedan and his highly engaged team.

“The implementation was 100% remote, which makes it more challenging but of course even more valuable when you consider the results we got,” says Barbarino. “It requires a lot of commitment from the asset team to make it work because we were not there to train them. Ahmed’s leadership was vital in making this project successful.”

How Leucipa scales across workflows

The scalability and flexibility of Leucipa means that it can connect with existing systems to deliver results for customers in as little as two weeks, even for customers just beginning their digital transformation journey.

SOO has continued to work with Barbarino’s team to add other Leucipa modules across multiple workflows. “What we like about Leucipa is that our engineers can think about any workflow or sophisticated engineering problem and talk to the experts at Baker Hughes,” says Swedan. “We identify the data inputs and how it will be processed and then they add it to our dashboards, and it becomes a model that anyone can use.”

Swedan says his team is increasingly engaged with the potential of adding and refining the models, with support from Baker Hughes counterparts.

“Our reservoir engineers see the time that they are saving every day and the benefits they are getting from these models,” Swedan says “They are encouraged to think about adding more models and trying to improve the ones we already have.”

That’s the scalability and flexibility.

“The advantage of Leucipa over other existing commercial software is that it’s not based on fixed features that you have to follow. Rather, you bring in your own problem and design a solution for it,” says Swedan. “You design it according to your standards and needs. For example, our models now include virtual metering optimization which saves cost and time, and the results are reliable.”

The engineers set up this model by doing physical monitoring, which is calibrated to negate the need for future physical testing.

“These kinds of workflows help us a lot.”

Leucipa has also led to more efficient ways to identify well interventions.

“The platform is connected to nine oilfields and more than 100 wells,” says Swedan. “Every well has the same setup, the same standards and they are identical in terms of data profile. The integration of all these models has let us move to a proactive mode rather than reactive.”

In 2024, SOO conducted 52 well interventions as best practice reservoir management – up from 15 in 2023. Swedan says Leucipa gave SOO the framework to enable this change. More efficient production operations have led to increased oil production and declining water production, making it more environmentally sustainable.

More frequent or proactive interventions can be better because they allow for earlier identification and resolution of production issues, ultimately leading to increased production, reduced downtime, and lower costs. This approach also enables better well optimization, potentially increasing the overall recovery factor of a field and reducing the need for new well drilling.

“Before Leucipa, we would try to do our operation planning by gathering all the data from different platforms into one folder once a year,” he recalls. “Now all that data is in one platform. Whenever we have a question or an issue we can join a quick video call, share the screen and discuss it and decide. Our activity of planning and executing those well interventions has increased dramatically, from 15 to 52. This is the first time in our history we’ve been able to decrease our water production while oil production exponentially increased – three years ago we were producing more water than oil. Now our operating costs have gone down.”

Swedan is rightly proud of SOO’s achievement. “First, we got stability of production. Then we got exponential growth,” he says. “And our water production is now on a continuous decline thanks to the workflow optimization and the synergy of the team from different departments along with unwavering management support to make things happen. When we look at the charts it shows the tremendous improvement in our production and efficiency.”

In 2024, SOO’s increased production accounted for more than 10% of Libya’s enhanced output. It’s an excellent case study of the 4Rs Swedan was aiming for – and the power of the combination of data excellence and human intelligence.

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.