Overview

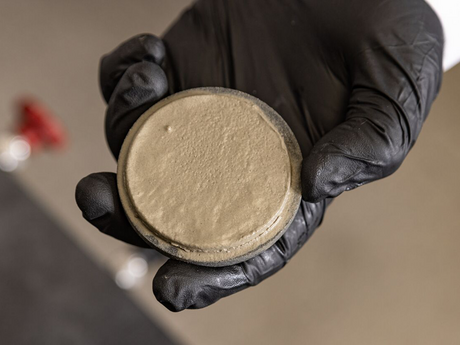

The PERFFLOW™ DIF system is engineered using monovalent and/or divalent brine with a specialized blend of non-damaging polymers and bridging particles that work together to develop a tough, thin, and pliable filter cake.

The fluid has excellent bridging characteristics across a wide range of permeabilities, up to 10 darcies. The dry components are stored in a single sack to aid in inventory management and mixing.

Although the PERFFLOW DIF system can be customized to match specific downhole conditions, the basic PERFFLOW DIF is engineered to deliver densities ranging from 9.1 to 17.8lb/gal (1.09 to 2.13 sg) and maintain excellent rheological properties in bottomhole temperatures up to 300°F (149°C).

The PERFFLOW™ IF intelligent reservoir drill-in fluid (DIF) is a non-damaging water-based system designed to improve the compatibility of filtrate with the reservoir fluid, reducing the risk of formation damage due to emulsions, scales, and fines migration in the near wellbore.

The PERFFLOW IF system is engineered with specific particle size distribution, enhancing properties, and minimizing fluid invasion.

The PERFFLOW™ NG reservoir drill-in fluid (DIF) is a next-generation, high-performance water-based system suitable for use in both in injection and production well operations. PERFFLOW NG system is designed to reduce skin factor, minimize lift-off pressure, and lower filtrate viscosity using non-damaging, acid-soluble products. The PERFFLOW NG system utilizes a multifunctional additive, resulting in an easily dispersed and acid-soluble filter cake.

Contact your local Baker Hughes representative to learn more about PERFFLOW™ drill-in fluids.