Highlights

Highlights

Benefits

- Ensure reliable setting without pipe manipulation

- Get a simple, robust system design to withstand downhole debris and solids

- Get increased reliability with hanger design that eliminates welded components

Applications

- Medium-to-long liner lengths

- High-angle wells

Overview

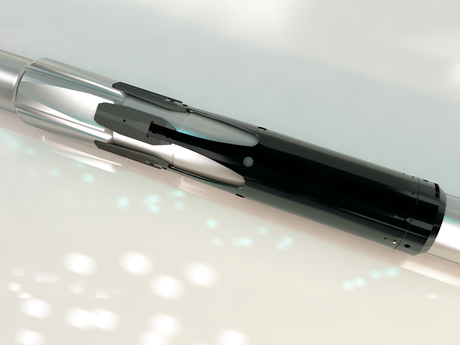

Get an assured, economical hanger solution for your medium-to-long liner lengths and high-angle wells with the BAKERLINETM hanger packer from Baker Hughes.

A non-welded slip-and-cone-style hydraulic hanger, the BAKERLINE hanger packer is designed to reliably withstand harsh downhole conditions that often cause corrosion issues.

With its convex-concave slip-and-cone geometry, the hanger reduces flexing and stress concentrations in the cone pads and slips. This unique geometry also ensures effective slip and cone contact in all host casing IDs within range, while providing a large distributed slip contact area that reduces stress in your supporting casing.

And because the BAKERLINE hanger packer is activated with applied hydraulic pressure, you save time and money by avoiding pipe manipulation and mechanical actuation to set.

This hanger packer also offers cylinder seals that have been API 11D1 V3 qualified to 10,000 psi (689.5 bar) for a temperature range of 82-300°F (27.8-148.9°C).

Built on decades of run history and field expertise, the BAKERLINE liner hanger packer has undergone the most stringent qualification and validation testing to ensure reliable operations in your wells.

Contact us to learn how the BAKERLINE liner hanger packer can reduce the costs and risks of your well construction.