Highlights

Highlights

Benefits

- Gain a reliable secondary pressure barrier in case primary cement fails

- Ensure a gas-tight barrier without requiring pressure or pipe manipulation to set the packer

- Eliminate the risk of dangerous gas migration in offshore wells

Applications

- Well construction operations, and plug and abandonment

- Completions operations

- Well production

Protect your people and the environment during all stages of the well lifecycle with the Cytadel ZX™ electronically actuated annular packer from Baker Hughes. This proven packer technology provides a primary or secondary V0-rated barrier to help reduce the risk of sustained casing pressure (SCP).

Get a gas-tight seal with less rigsite risk

Zonal isolation to reduce SCP is critical in today’s drilling operations, particularly in deepwater environments. The Cytadel ZX packer uses an electronic trigger mechanism to provide a gas-tight seal that delivers reliable wellbore integrity and reduces the risk of SCP-related blowouts.

The Cytadel ZX packer forms a secondary mechanical pressure barrier above the primary cement job in your well. The barrier eliminates gas migration and protects against SCP, which is particularly critical when downhole conditions compromise the sealing integrity of the casing cement.

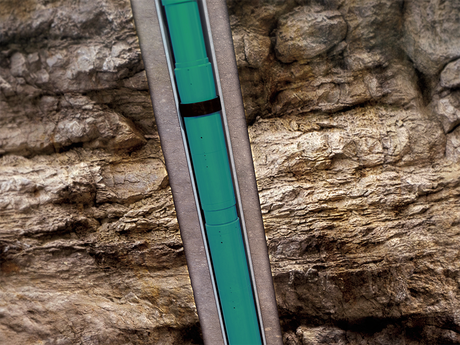

The Cytadel ZX packer comprises three fundamental components:

- A solid-body mandrel eliminates ports and O-rings and the potential for gas migration through the mandrel

- The industry-recognized zero-extrusion ZX™ seal element has proven reliable in 99.5% of more than 40,000 applications

- A unique modular electronic trigger mechanism, deployed and activated in one trip, eliminates the need for pressure or pipe manipulation to set the packer, improving rigsite efficiency and reducing risk

Remote actuation delivers a proven isolation solution

Designed for both onshore and offshore applications, the Cytadel ZX packer is run as part of a long-string completion and is positioned to isolate the casing-to-casing annulus. After the cementing operation, a unique surface signal activates the packer’s onboard electronics module, thus remotely actuating the packer. Once set, the packer provides an ISO 14310 V0-rated annular seal that eliminates the need for costly pressure bleed-off operations.

The Cytadel ZX packer was initially deployed to eliminate gas migration in offshore wells located in the Asia-Pacific region. The operator experienced fluid loss on several wells during completions operations, resulting in inconsistent cement jobs. The operator understood that casing and cement alone would not prevent gas migration.

Cytadel ZX packers were installed in two initial wells that exhibited the potential for channeling and cracking. Backside pressure tests on both wells confirmed that the packers were the only isolation solution consistently providing a gas-tight barrier in these wells. No recorded SCP events have been recorded since the packers were installed.

Contact us today to learn how the Cytadel ZX electronically actuated annular packer can provide you a proven solution to mitigate sustained casing pressure risks.