Highlights

Highlights

Benefits

- Ensure high-integrity seal without the conventional failure modes with through-the-flapper self-equalizing system

- Maximize sealing capabilities and ensure high tensile rating with metal-to-metal thread technology

- Eliminate explosive decompression and thermal degradation with nonelastomeric dynamic seal assembly

Applications

- Deep to shallow setting depths

- Onshore and offshore completions

Overview

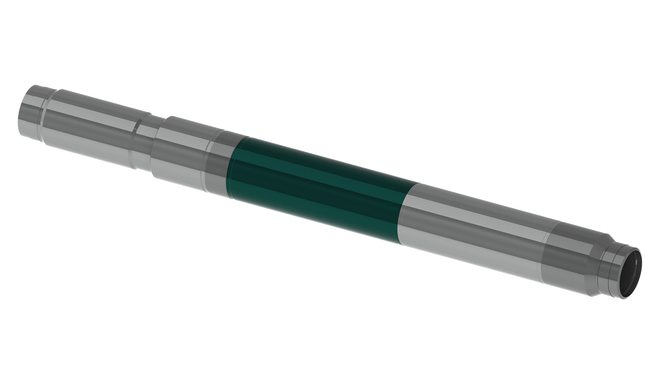

Get a reliable, secure seal in your full range of completion designs with the Thunder™ tubing-retrievable subsurface safety valve from Baker Hughes.

The latest addition to our portfolio of reliable tubing-retrievable subsurface safety valves (TRSSVs). Thunder valves leverage proven features from two widely proven and dependable valves—the Titan™ and T-Series™ valves. The result—a system that offers fail-safe operation at any setting depth, in almost any well.

Get an assured seal at the most extreme well conditions

The Thunder valve is designed for durability in extreme well environments. It can reliably withstand elevated temperatures as high as 300°F (149°C), accommodate working pressures from 5,000 to 10,000 psi (344.7 to 689.5 bar), and maintain fail-safe operation in depths from 1,000 to 9,300 ft (304.8 to 2834.6 m).

Thunder valves are available in two models:

- The standard model features metal-to-metal containment of wellbore fluids in the closed position and a slimline design—useful features in applications requiring a reduced valve diameter

- The Thunder-T model offers a more economical solution for applications where a slightly larger valve diameter is sufficient

Both models use the same puncture communication system as the T-Series valve, which provides an uninterrupted fluid path to the piston. By eliminating the possibility of accidental activation or inadvertent communication, this field-proven communication system helps minimize your costs while enhancing reliability.

Ensure reliability with proven design features

Thunder valves also incorporate a nonelastomeric dynamic seal assembly, which helps avoid explosive decompression and thermal degradation.

And a patented through-the-flapper, self-equalizing system provides high-integrity sealing—without the risks associated with conventional failure modes.

Thanks to detailed finite element analysis, rigorous testing, and decades of experience, Thunder valves offer you an ultra-strong flapper closure mechanism that will ensure reliable, long-term operation in a broad range of completions.

Each valve incorporates flapper design innovations that protect it from damage during your wireline operations. The Thunder valve recesses the sealing surface away from the flapper’s edge, which protects the flapper from damage when wireline cable drags across the edge.

The flapper design is also proven through high-flow-rate gas testing to avoid the flapper damage that can occur in high flow-rate wells during an uncontrolled slam closure.

Contact us to learn more about how our Thunder TRSSVs can ensure reliable, long-term operation in your well.