Overview

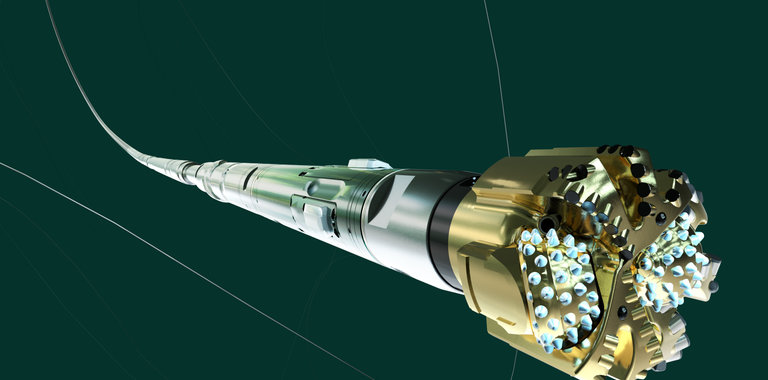

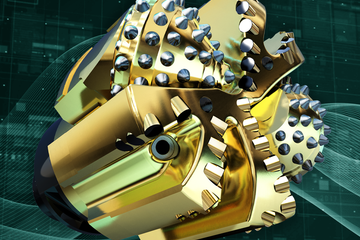

Kymera™ hybrid drill bit technology combines the cutting elements of both roller cone and polycrystalline diamond compact (PDC) bits into a single, patented design to reduce drilling time and trips in the most complex applications. Kymera is designed to take advantage of the best attributes of both bit types – a dual cutting mechanism with the crushing action of a roller cone and the shearing action of a PDC. Kymera drills faster than a roller cone and drills smoother with less torque and vibration than a PDC. This technology increases ROP, reduces drilling vibrations, improves directional control, and improves durability in challenging formations.

The Kymera Mach 6 hybrid bit’s novel design boosts both durability and drilling efficiency. A robust cutter layout improves shoulder durability and provides better core-out resistance to extend run length and improve dull conditions when drilling through the toughest rock.

The Kymera Mach 5 hybrid design package features precision balanced blade count and cone optimization, resulting in a proven performance step-change.

Higher ROP potential than roller cone bits

Roller cone bits drill smoothly, but they suffer from low ROP due to their low aggressive nature. Kymera hybrid bits increase bit aggressiveness without compromising the smooth drilling nature of a roller cone, resulting in higher penetration rates. Kymera bits require less weight on bit to drill than a roller cone and minimize bit bounce vibrations.

Better bit stability than PDC bits

Kymera hybrid bits deliver a smooth low torque drilling response compared to PDC bits, allowing them to drill with less vibrations for more consistent bit runs, better bit durability and reduced tool failures. The smooth torque response also provides better toolface control, resulting in more consistent and higher build rates to steer complex directional profiles. Kymera improves bit stability, reduces vibrations and improves directional control on both bent motor and rotary steerable bottom hole assemblies (BHAs).

Better durability for extended performance

Bit durability is critical for extending run lengths through challenging applications such as interbedded formations, hard rock, chert or inclusions. Kymera improves durability to extend run length and reduce the number of bits needed to complete a section. It reduces bit damaging vibrations such as stick-slip, keeping your bit sharper for longer to stay in the hole and reduce trips.

Baker Hughes continues to develop Kymera hybrid drill bit technology to widen the application range and deliver high performance in challenging applications. Baker Hughes hybrid drill bits are a proven replacement for conventional drill bit approaches, delivering faster, more durable, and more consistent drill bit performance.

Contact your local Baker Hughes representative to learn more about the Kymera hybrid bits.