i-Trak automated reservoir navigation service delivers first-of-a-kind well

See how, in close collaboration with Equinor and its partners, Baker Hughes delivered an amazing, first-ever application by autonomously navigating and drilling an extended lateral section using i-Trak™ drilling automation services.

Highlights

Benefits

- Boosts operational efficiency and ROP

- Reduces the risk of human errors

- Improves hydrocarbon recovery

- Ensures consistent, optimized wellbore placement for increased net-to-gross

- Streamlines steering decisions to reduce workflow related ILT and human errors

- Supports remote operations and minimizes personnel on board (POB)

Applications

- Horizontal drilling

- Thin reservoir targets

- Onshore and offshore wells

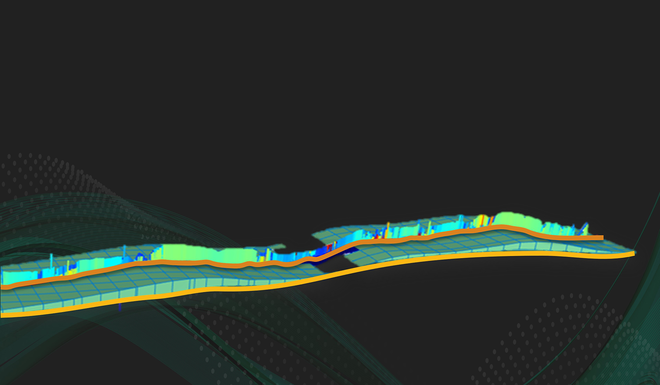

Autonomously navigate your well to the reservoir’s most productive zone—and keep it there—with the i-Trak™ automated reservoir navigation service (RNS) from Baker Hughes. By incorporating pre-well reservoir models, logging-while-drilling (LWD) data, proprietary algorithms, and advanced directional drilling, the i-Trak automated RNS gets your well to target depth (TD) with greater precision in less time.

Consistently identify the most productive well path

From the earliest stages of well design, the i-Trak automated RNS helps you make informed decisions that set your well up for long-term success.

During pre-well planning, the service uses existing downhole data to build a reservoir target map that presents the optimal well path for sustained production—and the optimal set of drilling parameters to maintain it.

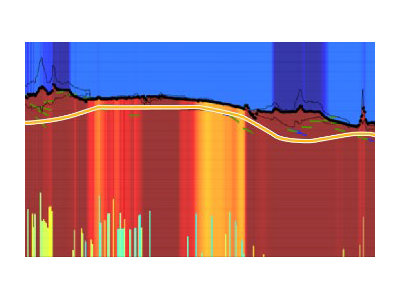

The service continuously monitors and analyzes real-time data from surface systems, directional measurement-while-drilling (MWD) sensors, and deep-reading azimuthal LWD tools.

The service compares actual well conditions to the reservoir target map, calculates wellbore deviation changes, and automatically updates drilling parameters to help subsurface and drilling teams efficiently adjust downhole drilling tools to stay in the target zone.

Streamline steering decisions

Traditional reservoir navigation methods can take up to 15 minutes for data review and steering path adjustments. The i-Trak automated RNS reduces this time to five minutes. The time saved in decision-making translates to faster drilling speeds, reduced invisible lost time (ILT), fewer course corrections, and improved well placement.

Set up the i-Trak automated RNS to run in advisory mode to guide your well construction team’s decisions or enable a fully automated operation. The automated approach is valuable in long horizontal sections that may require up to 80 individual navigation decisions prior to reaching TD.

Instead of wasting time manually processing data and debating decisions, your drilling team instantly receives specific steering recommendations.

Boost recovery with precise well placement

The i-Trak automated RNS’s ability to boost operational efficiency and improve well placement is proven in the field. One customer ran the service in shadow mode while their geosteering team monitored the drilling operation and made manual adjustments. After completing the section, the team determined that if they used the i-Trak automated RNS to geosteer, the well would have recovered an additional 100,000 bbls of hydrocarbon over its production life.

Contact your Baker Hughes representative to learn how the i-Trak automated RNS can reach your reservoir’s sweet spot faster for maximized drilling efficiency and ultimate recovery.