Understanding your well’s production flow profile is crucial to making decisions that increase reservoir production for the long term. Production Logging services from Baker Hughes efficiently and accurately measure your well’s production performance, regardless of your flow regime, well geometry, or completion type.

Rapid and reliable measurements for every scenario

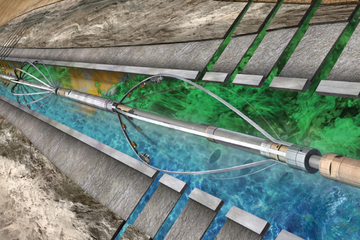

Configure our array production logging services to optimize measurements in vertical, highly deviated, or horizontal wellbores. Gain in-depth understanding of your production pathways in a wide range of well completion types, from open- to cased-hole and gravel-packed to slotted-liner configurations.

- Pinpoint the location of casing damage or collars with high efficiency and precision with our Casing Collar Locator (CCL) tool.

- Determine water holdup in your borehole, with a high degree of accuracy, with the Enhanced Capacitance Water Holdup (CWH) tool.

- Accurately determine the density of your wellbore fluid mixture, regardless of your well’s deviation, with our advanced Fluid Density Inertial (FDI) tool.

- Use low-energy gamma rays to determine downhole fluid density, safely and accurately, with the Fluid Density Radioactive (FDR) tool.

- Gain a reliable, full-bore measurement of your well’s gas volume fraction—independent of flow regime or well deviation—with our low-energy gamma ray Gas Holdup tool.

- Accurately measure flow rates in tubing, casing, and open holes and detect leaks with our compact, in-line and basket spinner flowmeters.

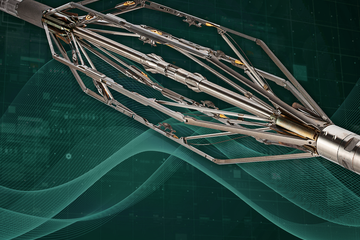

- Get detailed, multiphase evaluation of fluid velocity and phase identification in vertical, deviated, and horizontal wells with the PhaseView™ array production logging service.

- Accurately find fluid entry, gas leaks, injection zones, and cement tops via borehole fluid temperature analysis with the Platinum Resistance Thermometer (PRT) tool.

- Profile your flow regime in all types of well completions, flow rates, and production regimes with our caged fullbore and continuous production logging flowmeter spinners.

- Gain a continuous log of borehole fluid pressures to record pressure draw-down and build-up data with quartz pressure tools.

Sharpen your production analysis in a single pass

With production logging services from Baker Hughes, you’ll improve your reservoir management by determining and quantifying the relative contributions of completed intervals to your total production, while identifying areas of unwanted production like water channelling or gas coning.

You’ll also avoid lengthy downtime and resulting production problems through early detection of potential problems like water or gas breakthrough, crossflow of thief zones, channeling, and mechanical issues like holes in tubing or a leaking packer.

By using this comprehensive array of production logging tools with wireline cased-hole reservoir evaluation services like pulsed-neutron logging, you’ll get detailed borehole fluid hold-up, flow rates, and formation saturation measurements—all of which improve production management in complex and conventional wells alike.

And because you can run these production logging tools with reservoir evaluation services in a single run, you’re assured improved logging efficiency in any well environment.

Let us help you optimize your long-term well production with the right production logging solution.