Highlights

Highlights

Benefits

- Over 41% efficiency in simple cycle, or 56% in combined cycle

- High power output with the possibility for an additional 4 MW when configured with SPRINT option

- Capability to quickly ramp up and down to match demanding operating requirements

Features

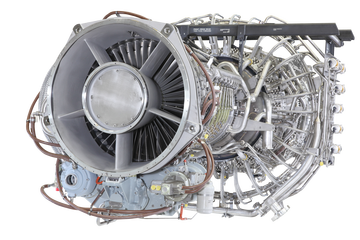

- Combustion system with well-proven DLE 1.5 technology

- High-pressure turbine rotor from CF6-80E aircraft engine for high operating temperatures

- Turbine airfoils optimized for high efficiency

Applications

- Onshore and offshore

- LNG, pipeline and gas storage

- Industrial, and combined heat and power

Overview

Overview

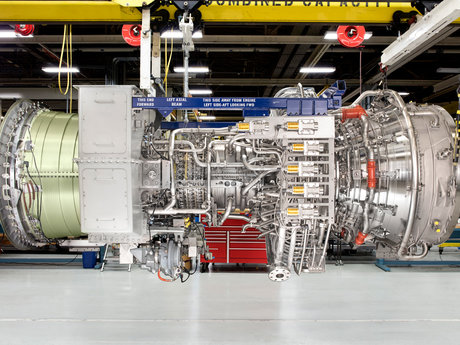

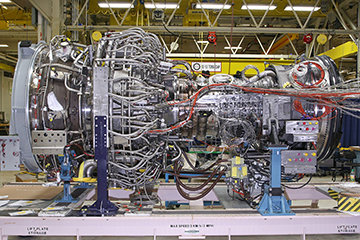

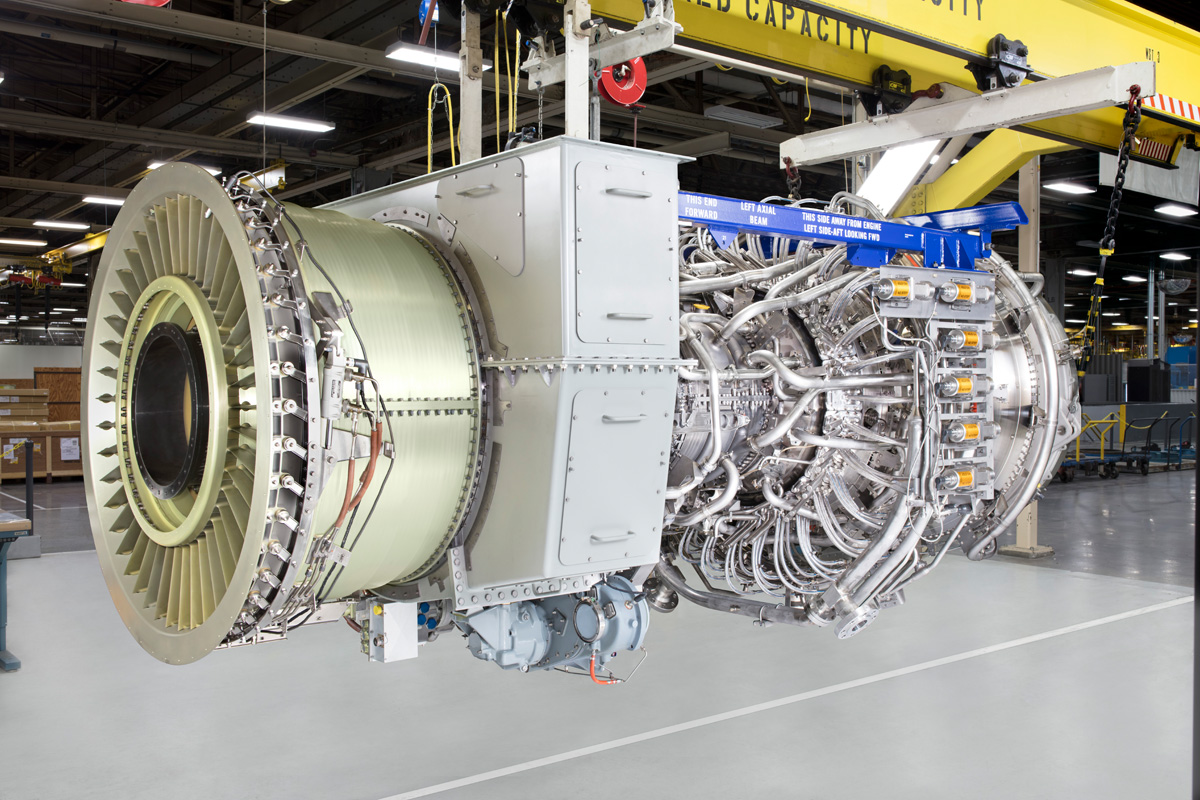

The LM6000PF+ aeroderivative gas turbine combines our latest innovations with the best proven technologies and operating experience from more than 5,000 aircraft engines with over 450 million flight hours, and 1,400+ LM6000 units with over 55 million operating hours in the last 30 years.

In September 2023, the LM6000PF+ overcame successfully 0.5 million operating hours.

Specification

Mechanical drive

Power (MW/HP)

53.8/72,150

Efficiency (%)

42

NOx emissions (ppm)

<25

Exhaust temperature (°C/°F)

498/928

Speed (rpm)

3,930

Borescope inspection (hours)

8,000

Hot Section inspection (hours)

25,000

Major inspection (hours)

50,000

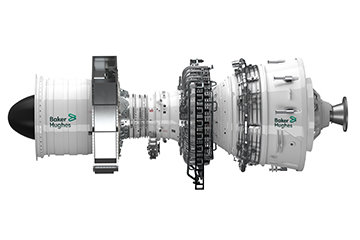

Package dimensions (m/ft)

11.5x5/37.7x16.4 (LxW)

Data for GT inlet conditions: 15ºC (59ºF) ambient temperature, 60% relative humidity, 101.3 kPa ambient pressure, considering no inlet or exhaust losses, and Standard Natural Gas. Extended maintenance plan is available to get higher availability from your plant; Contact Baker Hughes to define your customized service contract as per your needs. Package dimensions exclude driven equipment.

Specification

Power generation (50/60 Hz)

Power (MWe)

52.5

Efficiency (%)

41

NOx emissions (ppm)

<25

Exhaust temperature (°C/°F)

496/925

Speed (rpm)

3,930

Borescope inspection (hours)

8,000

Hot Section inspection (hours)

25,000

Major inspection (hours)

50,000

Package dimensions (m/ft)

20x5/65.6x16.4 (LxW)

Data for GT inlet conditions: 15°C (59°F) ambient temperature, 60% relative humidity, 101.3 kPa ambient pressure, considering no inlet or exhaust losses, and Standard Natural Gas. Extended maintenance plan is available to get higher availability from your plant; Contact Baker Hughes to check the extension capability as per your needs and your operability profile. Package dimensions include driven equipment. Efficiency and power in power-generation configuration at generator terminals.

Extended maintenance plan

Typical aeroderivative gas turbines have maintenance intervals of 8,000, 25,000, and 50,000 hours. The LM6000PF+ aeroderivative gas turbine is designed to extend those intervals to 10,000, 30,000, and 60,000 hours (contact Baker Hughes to check the extension capability as per your needs and your operability profile). This significantly increases the unit’s availability and production—which is particularly ideal for LNG plants.

Enhanced performance

Designed to deliver 53.8 MW with over 42% efficiency, the LM6000 PF+ aeroderivative gas turbine has the best $/kW in its power class. It’s also more reliable and flexible than other options in its class—able to start in less than five minutes and reach full power in 10 minutes or less.

It’s ideal in Liquefied Natural Gas application thanks to its pressurized LNG compressor startup capability, without helper motor assistance.